Fully automatic multi-station multi-axis CNC machining center

A machining center, multi-station technology, used in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of large centrifugal force, shorten the service life of CNC machining centers, and inconvenient use of CNC machining centers, and reduce the center of gravity. offset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is attached Figure 1-4 The present invention is described in further detail.

[0036] The embodiment of the invention discloses a fully automatic multi-station multi-axis numerical control CNC machining center.

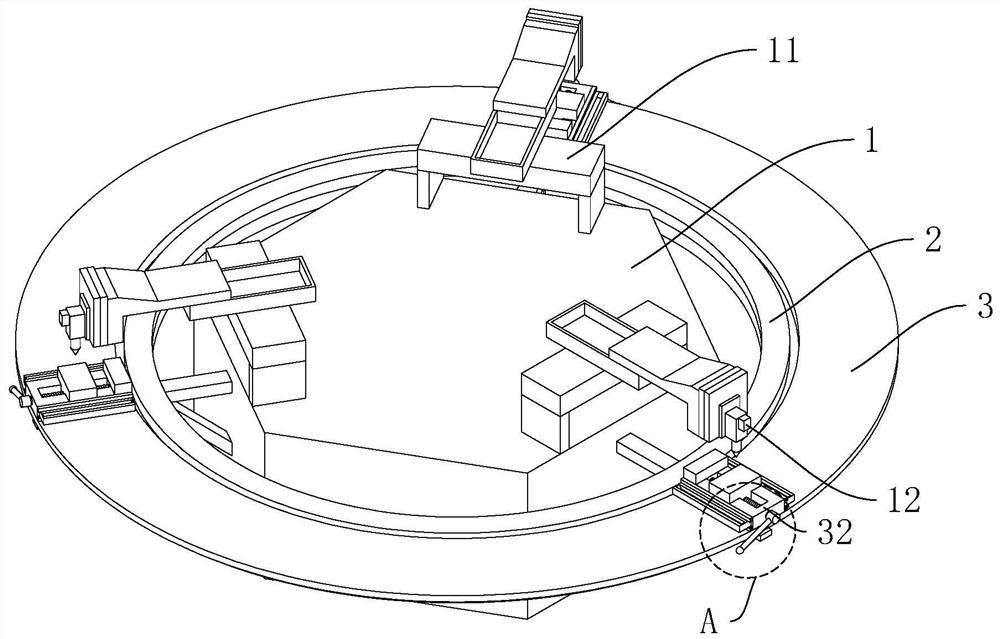

[0037] refer to figure 1 , a fully automatic multi-station multi-axis CNC machining center, including a fixed table 1, a plurality of multi-axis CNC bodies 11 are fixed on the top of the fixed table 1, in this embodiment, the number of multi-axis CNC bodies 11 There are three, and three multi-axis CNC machine bodies 11 surround equidistantly along the top outer edge of the fixed table 1 .

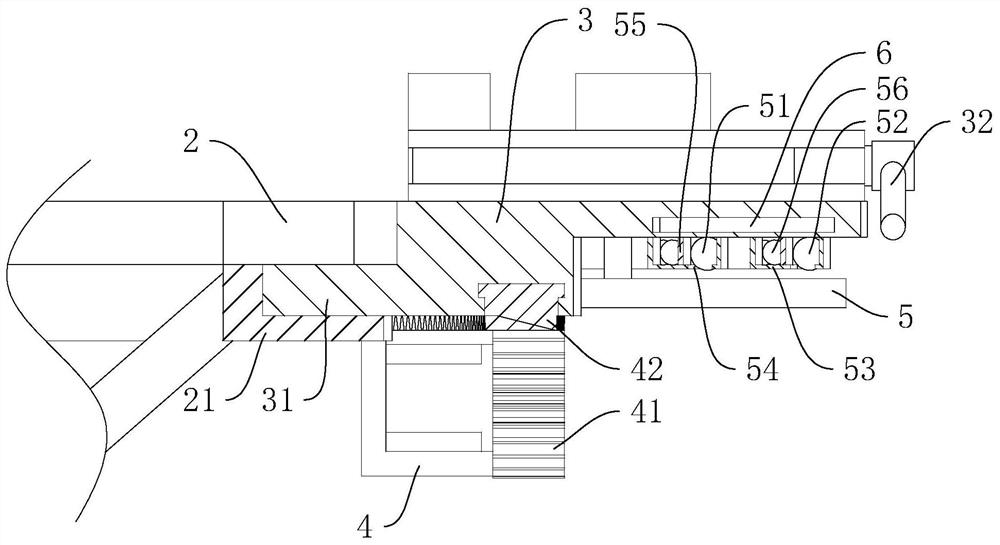

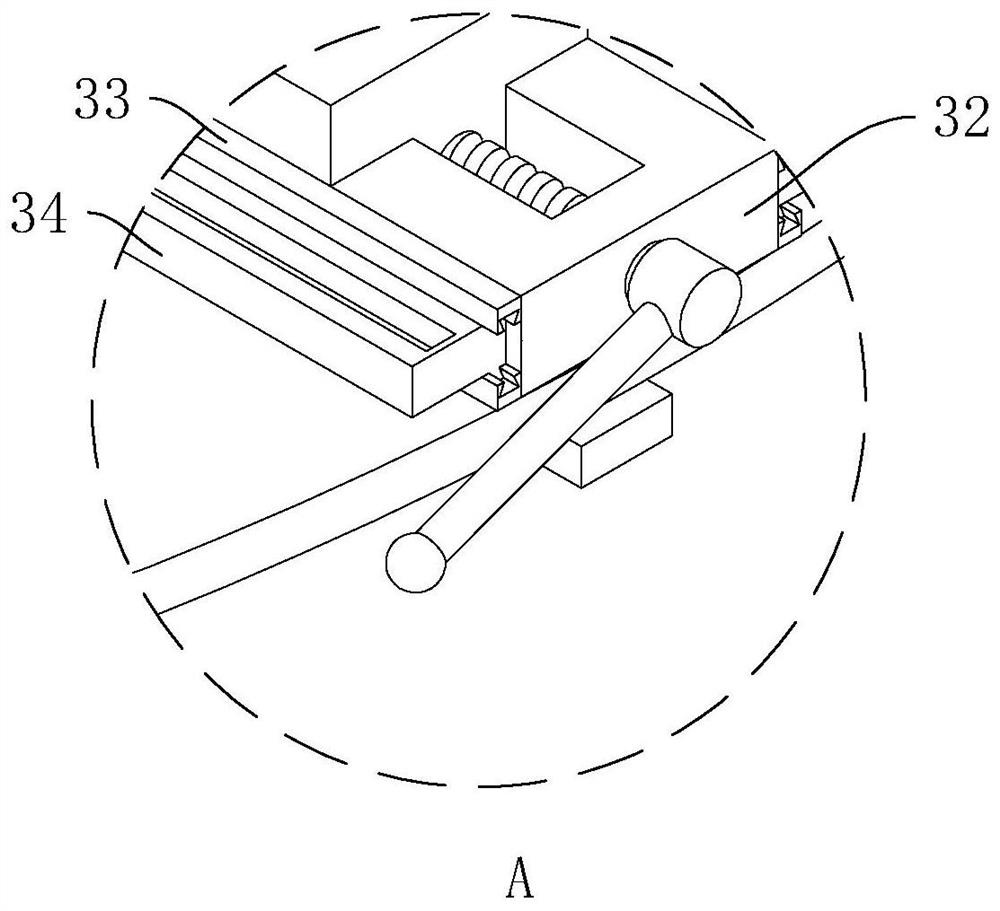

[0038] At the same time, refer to figure 2 , the ring platform 2 is arranged on the outer edge of the fixed platform 1, and the base slide rail 21 is arranged on the bottom ring of the ring platform 2. In addition, the turntable 3 is arranged on the outer edge of the ring platform 2, and the bottom of the turntable 3 is fixed. There is a vise 32 that is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com