Manufacturing and machining machine and machining method for reducing copper pipe connector

A technology for processing machinery and connectors, which is applied in the field of grinding and manufacturing of copper pipe connectors, and can solve the problems of rough inner wall, discharge of waste chips, and burrs on the surface of copper tube connectors with different diameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

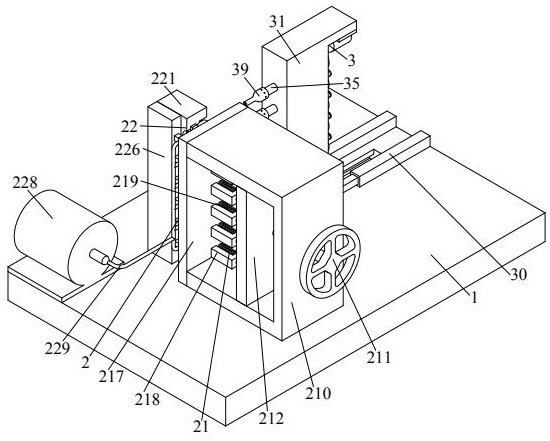

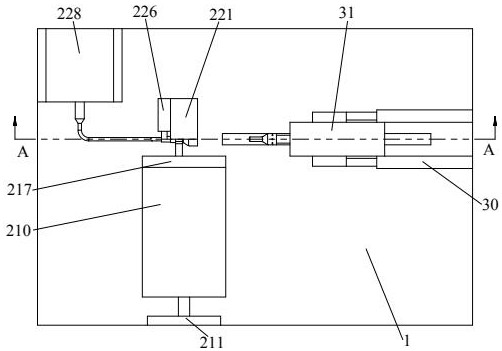

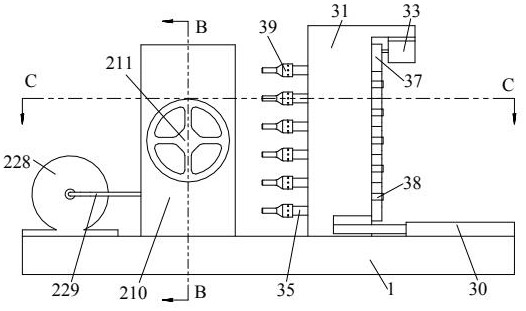

[0036] In order to make the technical means, the creation of the present invention, the purpose and energy is easy to understand, the following combinations Figure 1 to 11 Further, the invention is further illustrated.

[0037] An aerated copper pipe connection head manufacturing machine, including the bottom plate 1, the fixing device 2, and the grinding device 3, and the upper end is mounted in the upper end of the bottom plate 1, and the fixing device 2 is disposed on the right side of the fixing device 3, the grinding device 3. Installed on the top of the upper end of the bottom plate 1.

[0038] like figure 1 As shown, the fixing device 2 includes a fixing mechanism 21 and a tensioning mechanism 22, and the upper end of the bottom plate 1 is sequentially mounted from the back to the back to the locking mechanism 22, and when the specific operation, the absence of the absence of treatment The copper pipe connection head is placed between the fixing mechanism 21 and the tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com