Textile wrinkle removing mechanism

A textile and mechanical technology, applied in the field of textile wrinkle removal mechanism, can solve the problems of affecting the color and smoothness of textiles, unsatisfactory wrinkle removal effect, and lower textile quality, so as to improve ironing efficiency, improve wrinkle removal effect, and reduce motor pressure. The effect of the amount used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

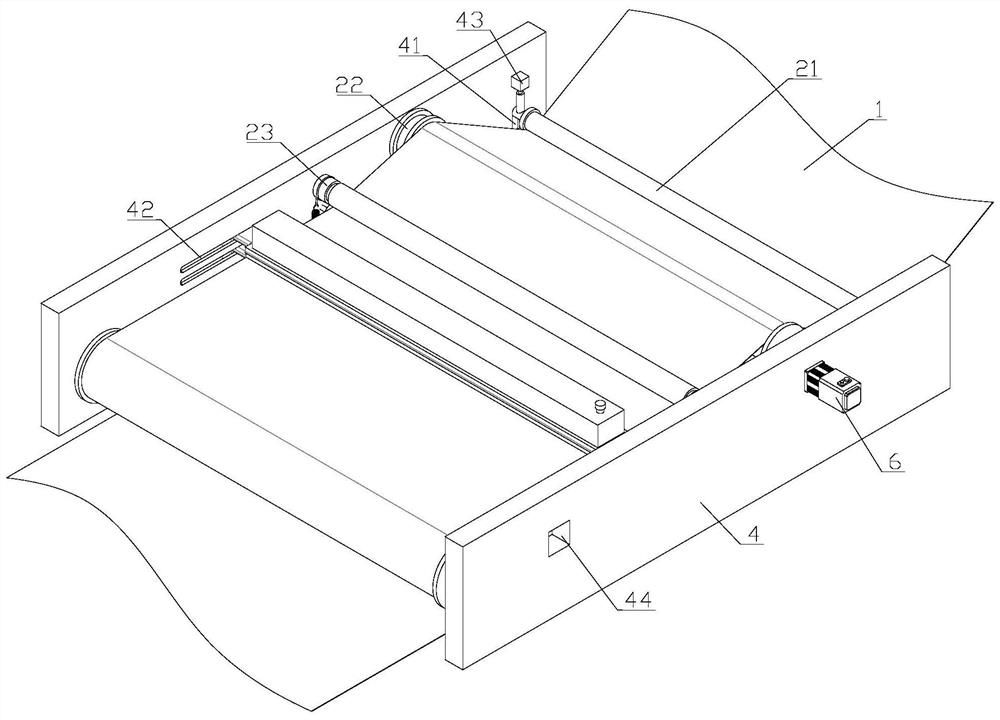

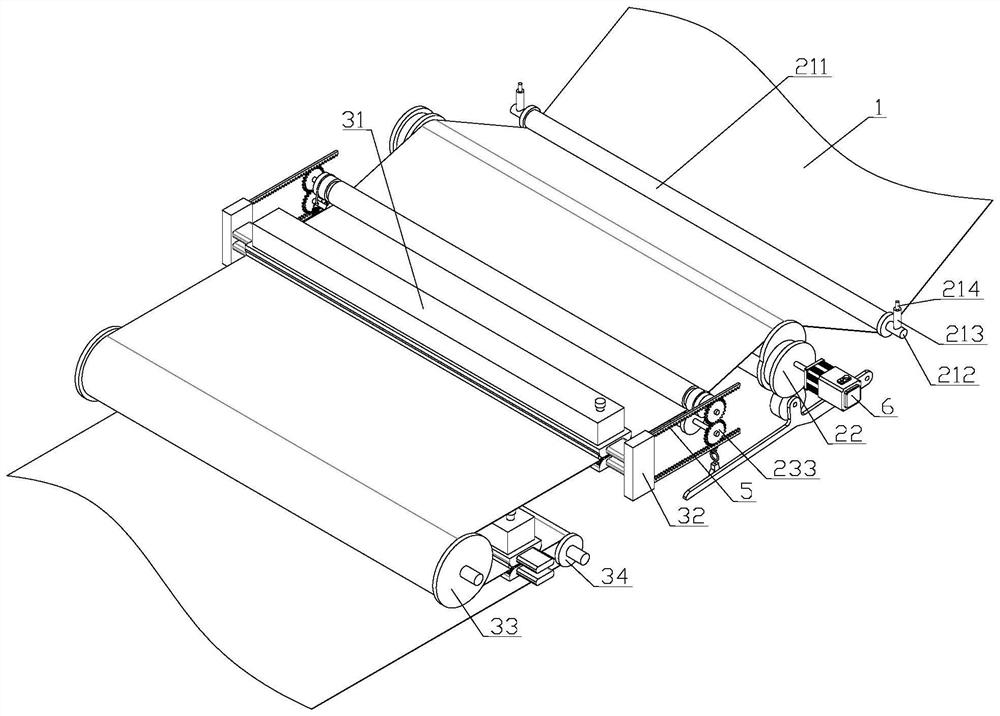

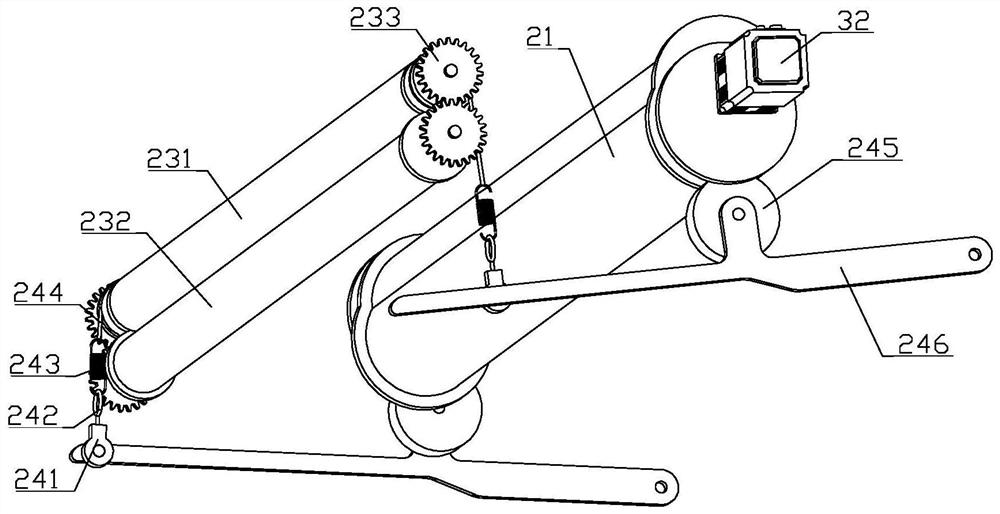

[0043] see Figure 1 to Figure 9 , the embodiment of the present invention provides a textile wrinkle removal mechanism, which includes a base 4, a mechanical wrinkle removal unit and an ironing unit sequentially arranged between the bases 4 along the traveling direction of the cloth 1, and a motor 6 for controlling the mechanical wrinkle removal unit ;

[0044] The mechanical wrinkle-removing unit includes a tightening assembly 21, a wrinkle-removing roller 22 and a smoothing assembly 23 arranged in sequence along the traveling direction of the cloth 1, wherein the tightening assembly 21 cooperates with the wrinkle-removing roller 22 to pull the cloth 1 evenly, and then the smoothing assembly 21 The flattening component 23 performs smoothing operation on the pulled cloth 1, which facilitates the subsequent ironing operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com