Clothes dryer filter screen clogging detection method and clothes dryer

A filter clogging and detection method technology, which is applied to household clothes dryers, textiles and papermaking, climate sustainability, etc., can solve the problems of complex detection methods, low accuracy, filter clogging, etc., and achieve good real-time performance, The effect of high accuracy and simple detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

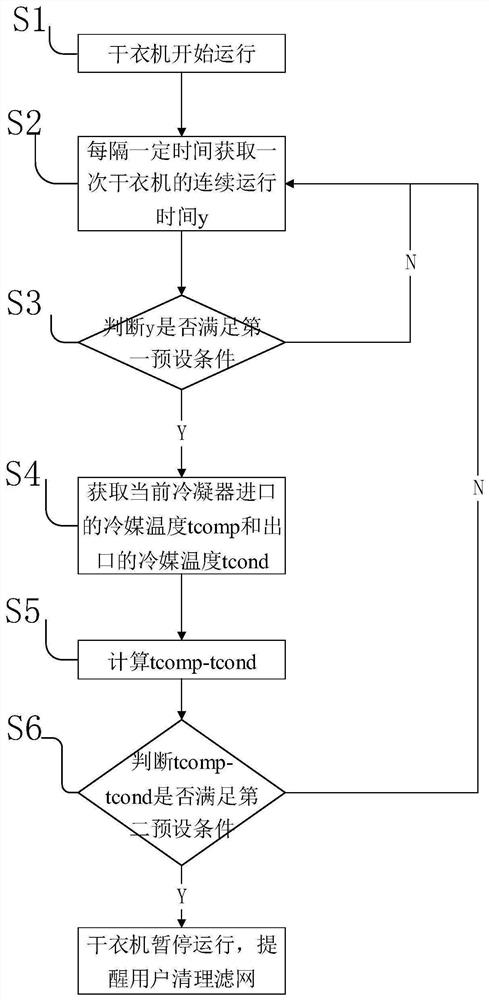

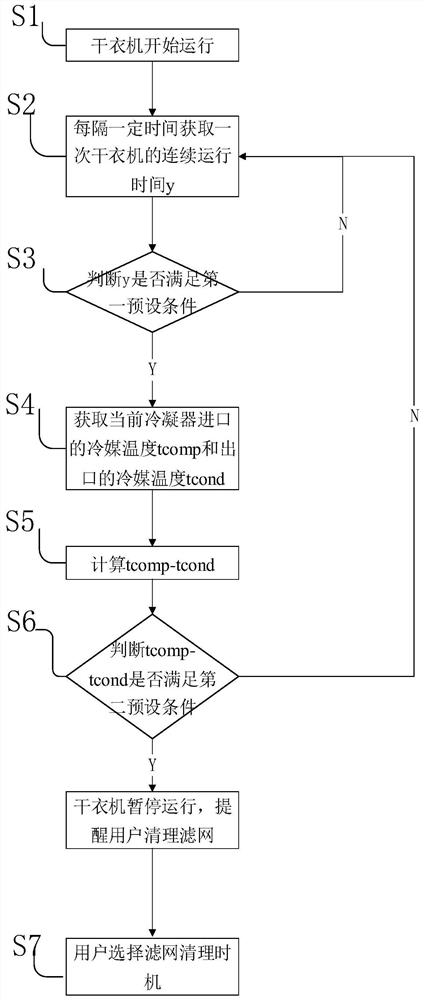

[0054] like Figures 1 to 2 As shown, a method for detecting clogging of a clothes dryer filter screen includes the steps of:

[0055] S1, the dryer starts to run;

[0056] S2, obtain the continuous running time y of the clothes dryer at regular intervals;

[0057] S3, judging whether the continuous running time y of the dryer satisfies the first preset condition; if so, continue to perform step S4, if not, then the dryer is running normally, and continue to perform step S2;

[0058] S4, obtain the current refrigerant temperature tcomp at the inlet of the condenser and the current refrigerant temperature tcond at the outlet of the condenser;

[0059] S5, calculate the value of the current tcomp-tcond;

[0060] S6, determine whether the current value of tcomp-tcond satisfies the second preset condition; if so, the dryer suspends operation to remind the user to clean the filter screen; if not, the dryer runs normally, and proceeds to step S2.

[0061] Wherein, the first pres...

Embodiment 2

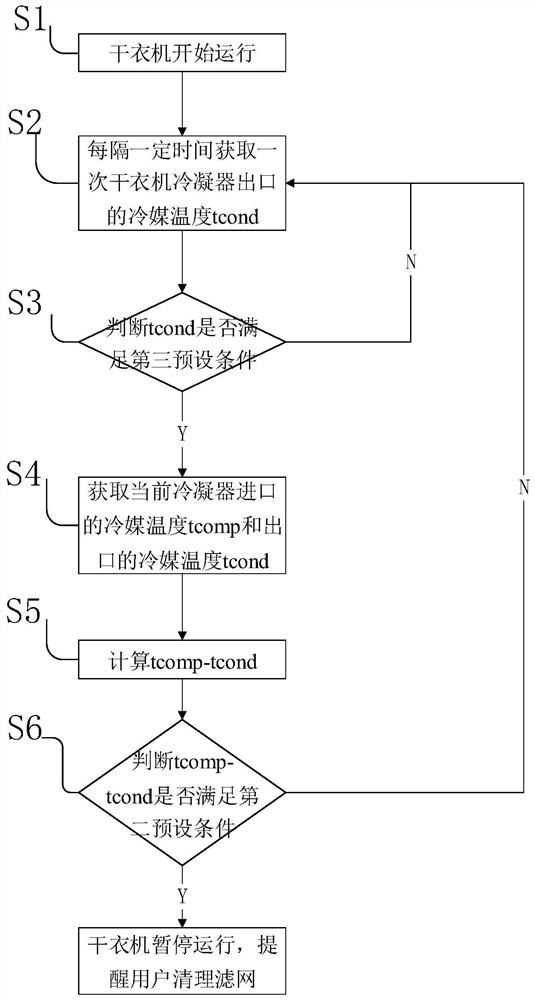

[0075] like image 3 As shown, a method for detecting clogging of a clothes dryer filter screen includes the steps of:

[0076] S1, the dryer starts to run;

[0077] S2, obtain the refrigerant temperature tcond at the condenser outlet of the dryer at regular intervals;

[0078] S3, judging whether the temperature tcond of the refrigerant at the outlet of the condenser satisfies the third preset condition; if so, continue to perform step S4, if not, the clothes dryer is running normally, and continue to perform step S2;

[0079] S4, obtain the current refrigerant temperature tcomp at the inlet of the condenser and the current refrigerant temperature tcond at the outlet of the condenser;

[0080] S5, calculate the value of the current tcomp-tcond;

[0081] S6, determine whether the current value of tcomp-tcond satisfies the second preset condition; if so, the dryer suspends operation to remind the user to clean the filter screen; if not, the dryer runs normally, and proceeds ...

Embodiment 3

[0088] like Figures 4 to 5 As shown, a method for detecting clogging of a clothes dryer filter screen includes the steps of:

[0089] S1, the dryer starts to run;

[0090] S2, obtain the condenser outlet refrigerant temperature tcond of the dryer and the continuous running time y of the dryer at regular intervals;

[0091] S3, judging whether the continuous running time y of the dryer satisfies the first preset condition; if so, continue to perform step S4, if not, continue to judge whether the condenser outlet temperature tcond satisfies the third preset condition; If yes, continue to step S4, if not, the clothes dryer is running normally, and continue to execute step S2;

[0092] S4, obtain the current refrigerant temperature tcomp at the inlet of the condenser and the current refrigerant temperature tcond at the outlet of the condenser;

[0093] S5, calculate the value of the current tcomp-tcond;

[0094] S6, judging whether the current value of tcomp-tcond satisfies t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com