Comprehensive pipe gallery joint system and comprehensive pipe gallery

A technology of integrated pipe corridors and nodes, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of many ground facilities and affect the coordinated construction of roads, and achieve the effect of reducing ground facilities and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

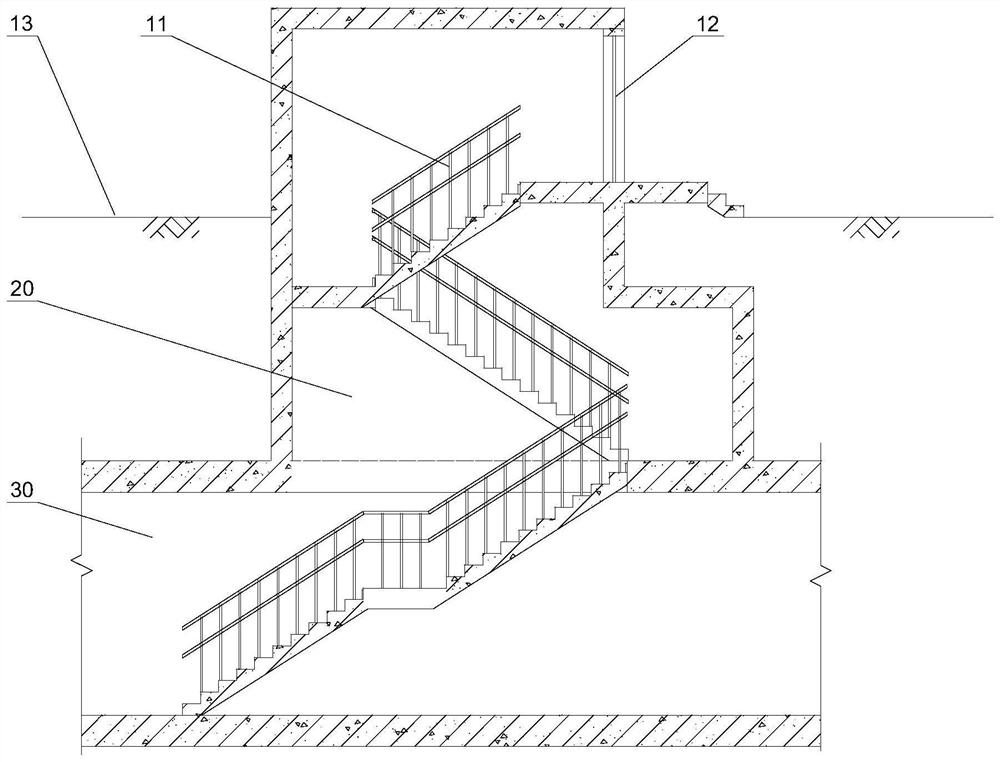

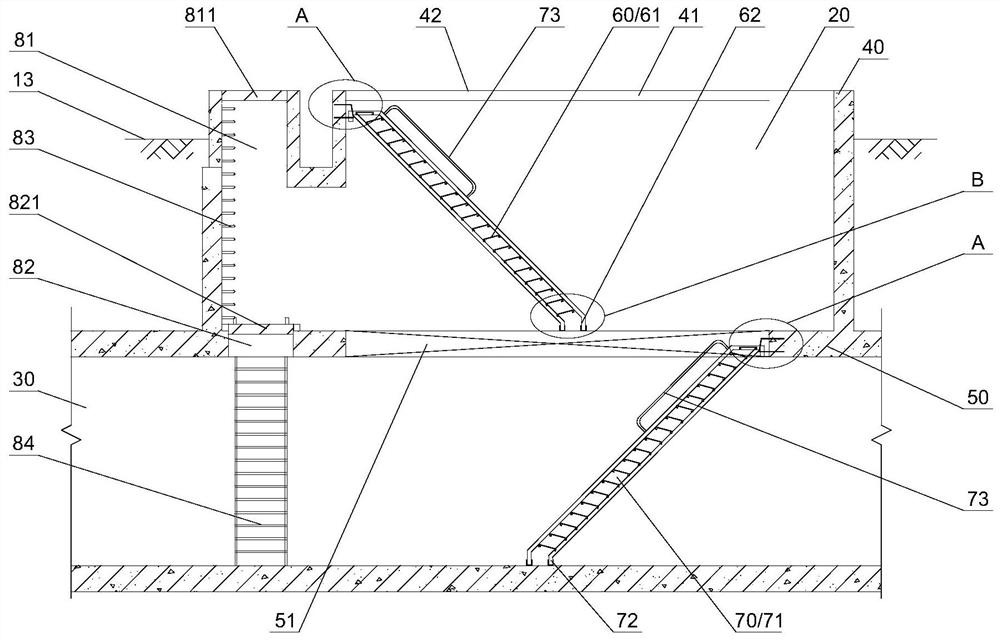

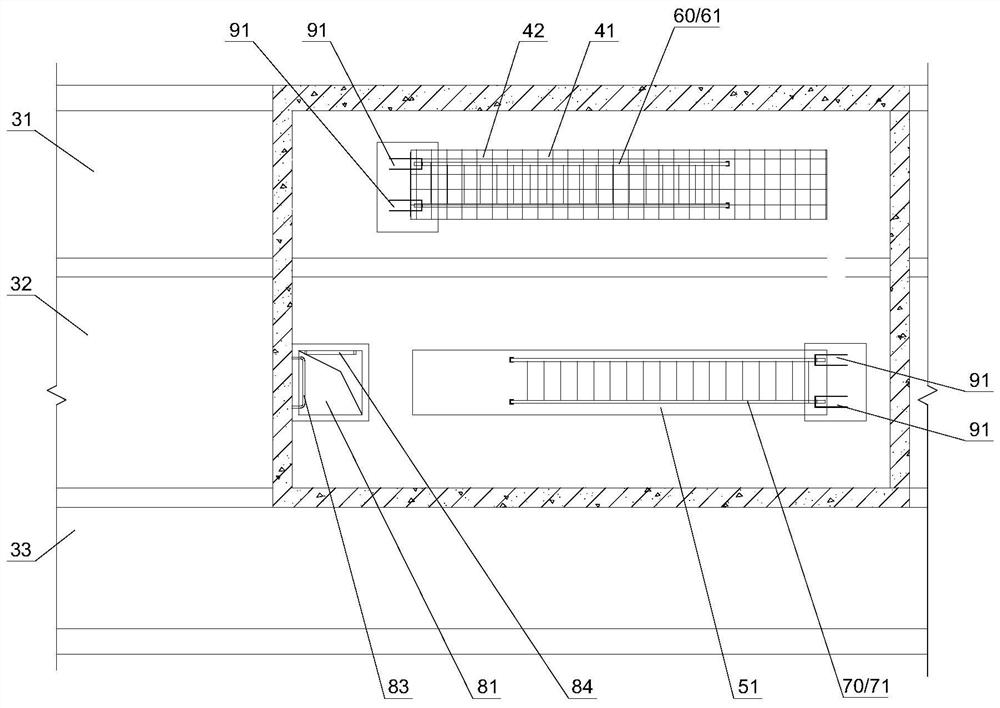

[0037] The present invention provides a comprehensive pipe gallery node system, such as figure 2 and image 3 As shown, the node system includes an interlayer 20 and a pipe corridor layer 30 distributed sequentially from top to bottom, the interlayer 20 is at least partly higher than the ground 13; the top of the interlayer 20 is provided with an interlayer roof 40, and the interlayer roof 40 is preset with a first hole 41, The interlayer 20 is equipped with a detachable interlayer movable staircase 60, and the interlayer movable staircase 60 is configured to allow personnel to go down to the bottom of the interlayer 20 through the first hole 41; 50 is preset to connect the second hole 51 between the interlayer 20 and the pipe gallery layer 30. The pipe gallery layer 30 is equipped with a detachable pipe gallery floor movable staircase 70, and the pipe gallery floor movable staircase 70 is configured for people to pass through the second hole 51 To the bottom of the pipe cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com