A hatch cover jacking and moving method

A hatch cover and jacking technology, which is applied in the direction of lifting frame, lifting device, ship hatch/hatch, etc., can solve the problems of great influence on installation, shortage of crane resources, and many times of hatch cover lifting, so as to achieve installation and operation It is simple, meets the requirements of oil cylinder hoisting, and alleviates the effect of crane resources on the wharf

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] refer to Figure 1 to Figure 6 , the present invention is a hatch cover jacking moving method, which comprises the following steps:

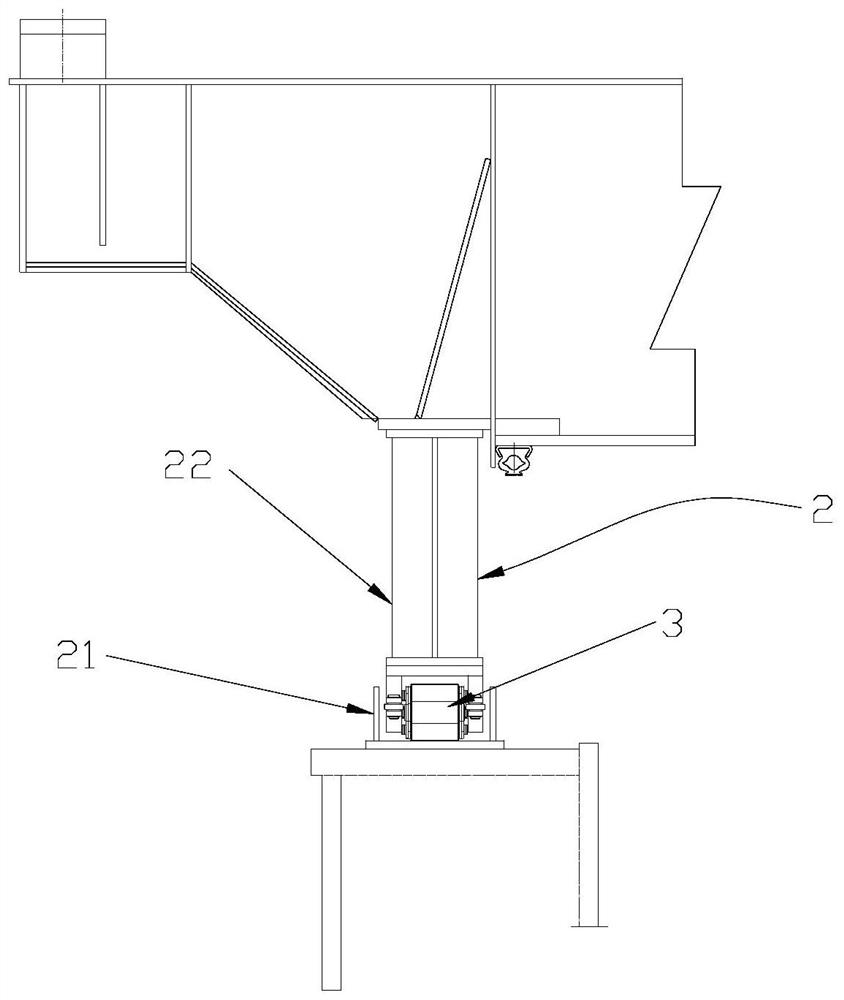

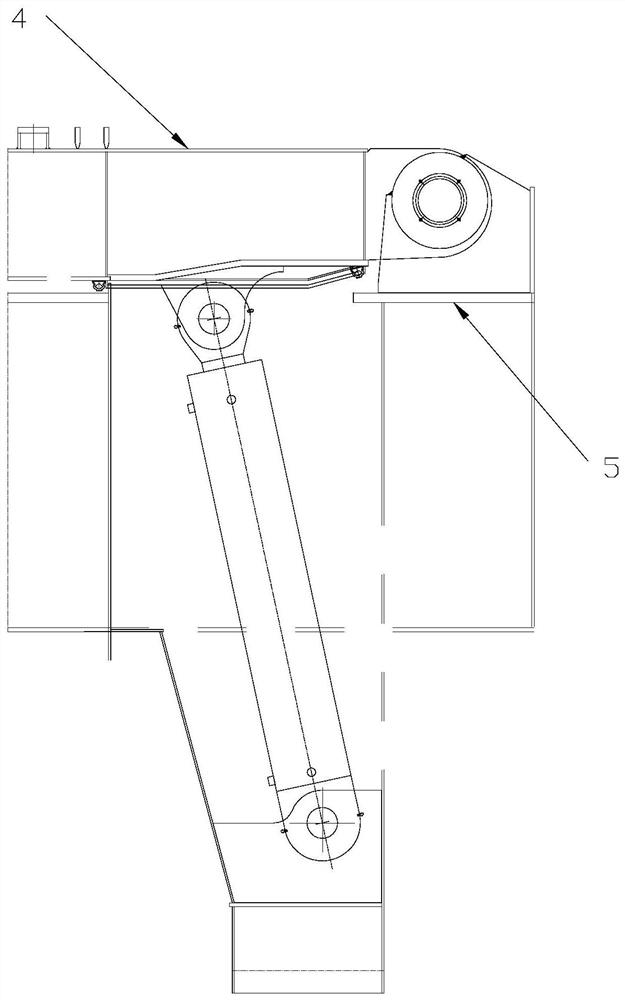

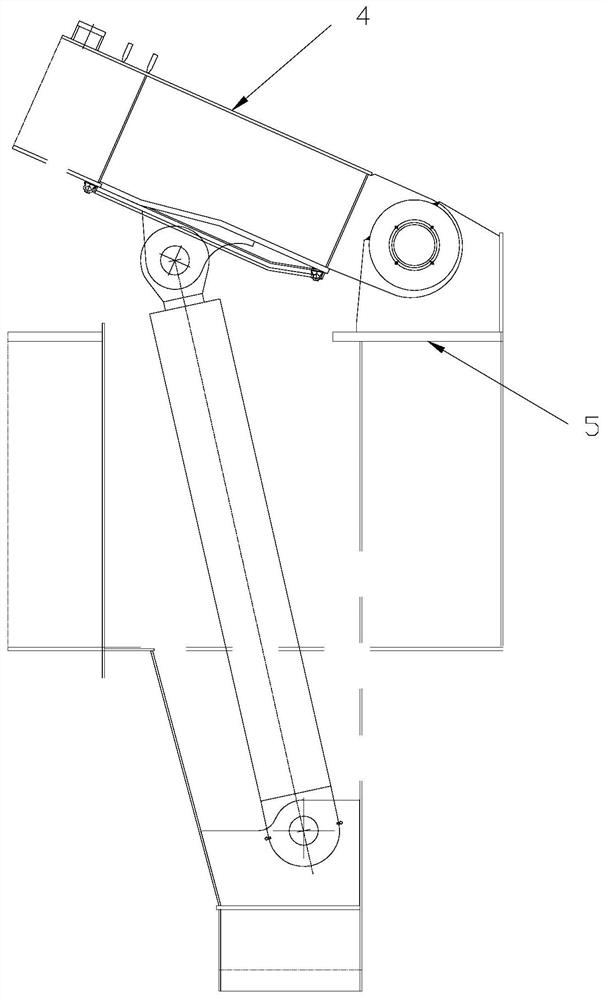

[0028] S1: Design jacking tooling 1, moving tooling 2, and sliding trolley 3. Before the hatch cover 4 is on board, hoist the lower ear plate of the hatch cover hinge and the dummy shaft-like rod into the oil tank cabin. Specifically, the mobile tooling 2 includes a guide rail 21 and a support pier 22 , the guide rail 21 is spot welded and fixed on the hatch coaming 5 , and the support pier 22 is installed at the bottom of the hatch cover 4 . The jacking tool 1 includes a jacking oil top 11 and a jacking platform 12, the jacking platform 12 is installed at the lifting lug position of the hatch cover, and the jacking oil top 11 is installed on the hatch coaming and the jacking platform 12. Between pallets 12. Among them, the lifting tooling 1 and the moving tooling 2 are welded with GFL-71 welding rods, and all welding legs are ≥7mm; aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com