Connecting joint of fabricated steel-timber combined truss

A technology of combining trusses and connecting nodes, which is applied in the direction of architecture and building construction, can solve problems such as failure to meet structural force requirements, low installation efficiency, and large node loads, and achieve good architectural applicability, improve installation efficiency, and improve The effect of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

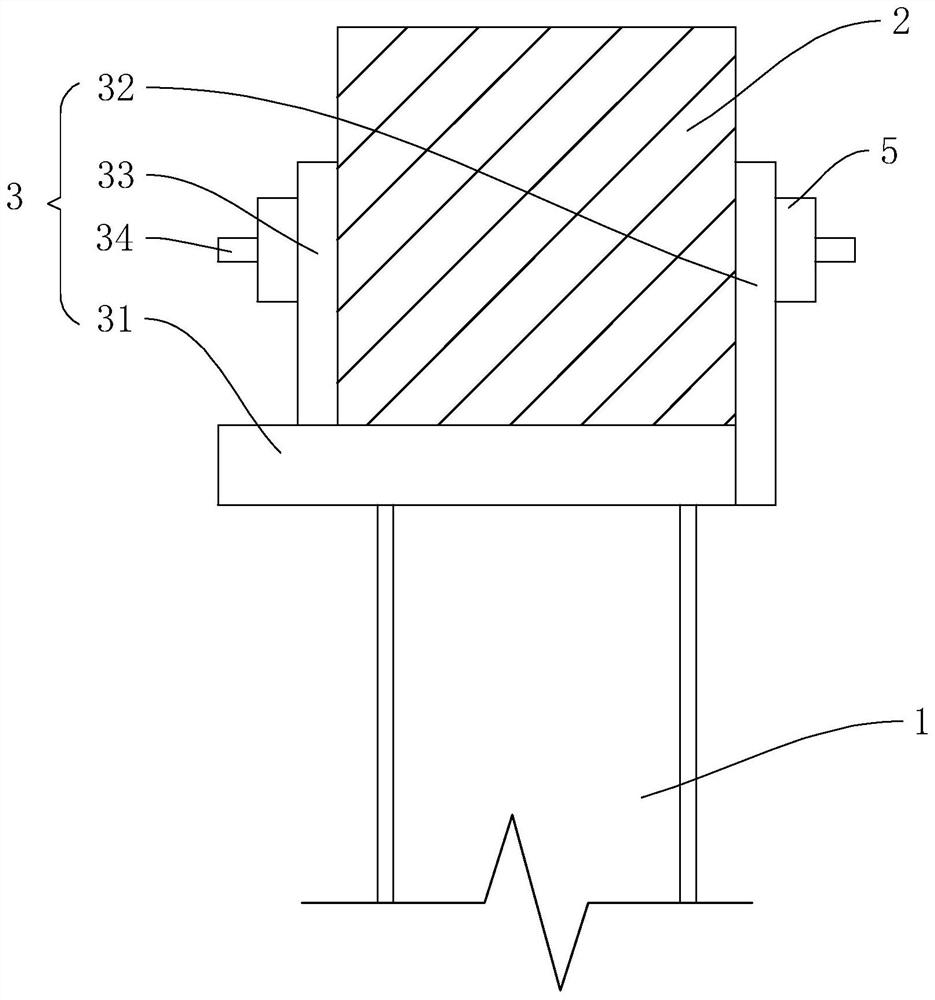

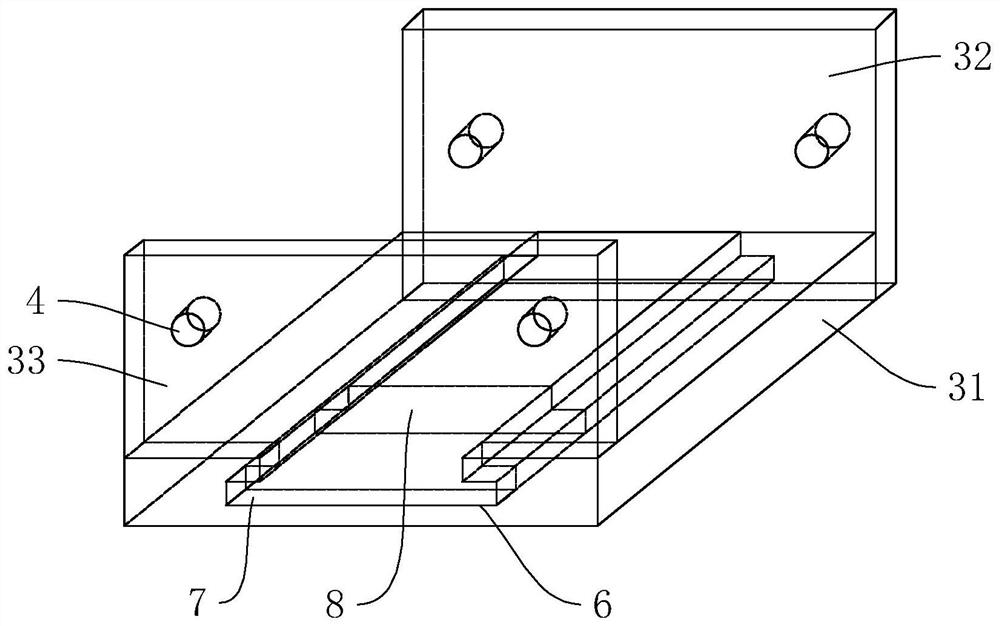

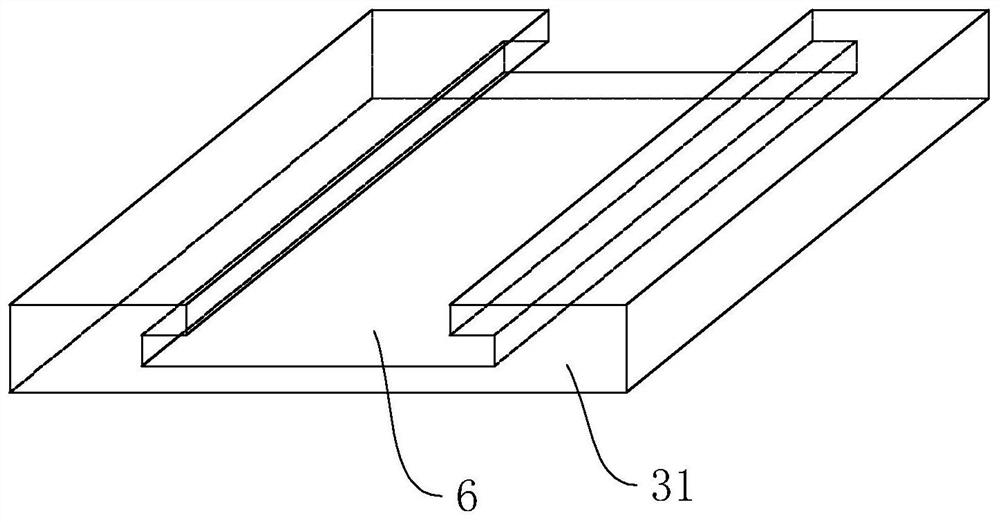

[0042] refer to figure 1 , figure 2 As shown, the connection node includes a steel member 1, a square log 2 and a connection assembly 3, the steel member 1 and the square log 2 are connected through a connection assembly 3, and the connection assembly 3 includes a connection plate 31, a first limit plate 32, a second limit plate Plate 33 and locking member 34, the first limiting plate 32 and the second limiting plate 33 are clamped to the square log 2 both sides, the first limiting plate 32, the second limiting plate 33 and the square log 2 are all provided with The mounting holes 4 provided on the same axis, the locking member 34 passes through each mounting hole 4 and cooperates with the nut 5 to lock and fix the first limiting plate 32 and the second limiting plate 33 to both sides of the square wood 2, the first limiting plate Both the lower end of the plate 32 and the second limiting plate 33 are connected with the connecting plate 31, and the lower end of the connectin...

Embodiment 2

[0048] refer to Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the filling plate 8 is divided into several sub-boards of equal specifications and spliced together, and the arrangement direction of each sub-board is consistent with the sliding direction of the second limiting plate 33 .

[0049] The implementation principle of embodiment 2 is as follows: the difference from embodiment 1 is that when plugging in the filler boards 8, a corresponding number of sub-boards are plugged and installed according to the actual site conditions.

Embodiment 3

[0051] refer to Figure 6 , Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the lower end of the connecting plate 31 is welded and fixed with the first ear plate 9, the end of the steel member 1 is fixed with the end plate 11, and the end plate 11 is fixed with the second ear plate 10. In this embodiment, there are two pieces of the first lug plate 9, and one piece of the second lug plate 10. The second lug plate 10 and the two pieces of the first lug plate 9 are coaxially penetrated with a shaft hole 12, corresponding to the shaft A pin shaft 13 is rotatably installed in the hole 12 , thereby realizing the hinge connection effect between the first ear plate 9 and the second ear plate 10 , and further realizing the oblique connection between the steel member 1 and the square timber 2 .

[0052] The implementation principle of Embodiment 3 is as follows: the difference from Embodiment 1 is that before the on-site construction, the first ear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com