Warm precision forging forming conveying equipment for gear

A conveying equipment and precision forging technology, which is applied in metal processing equipment, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve problems such as low production efficiency, workers' vulnerability to burns, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

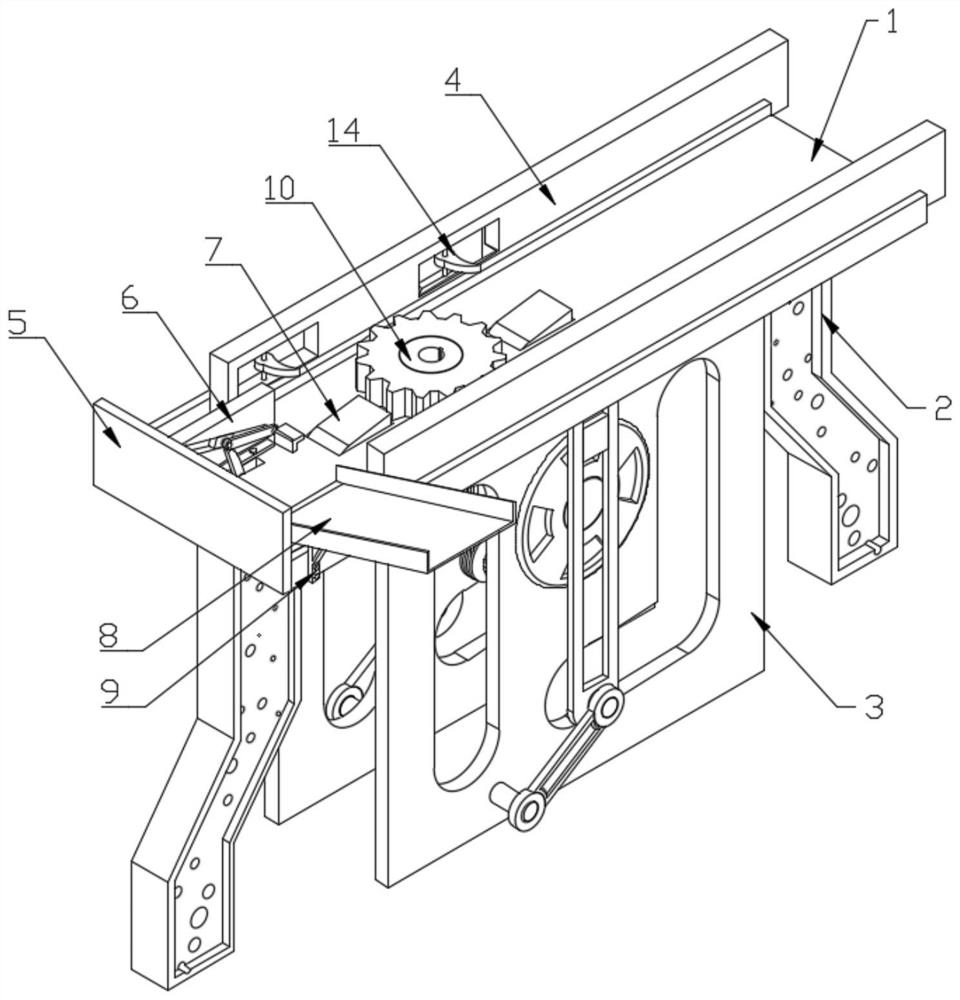

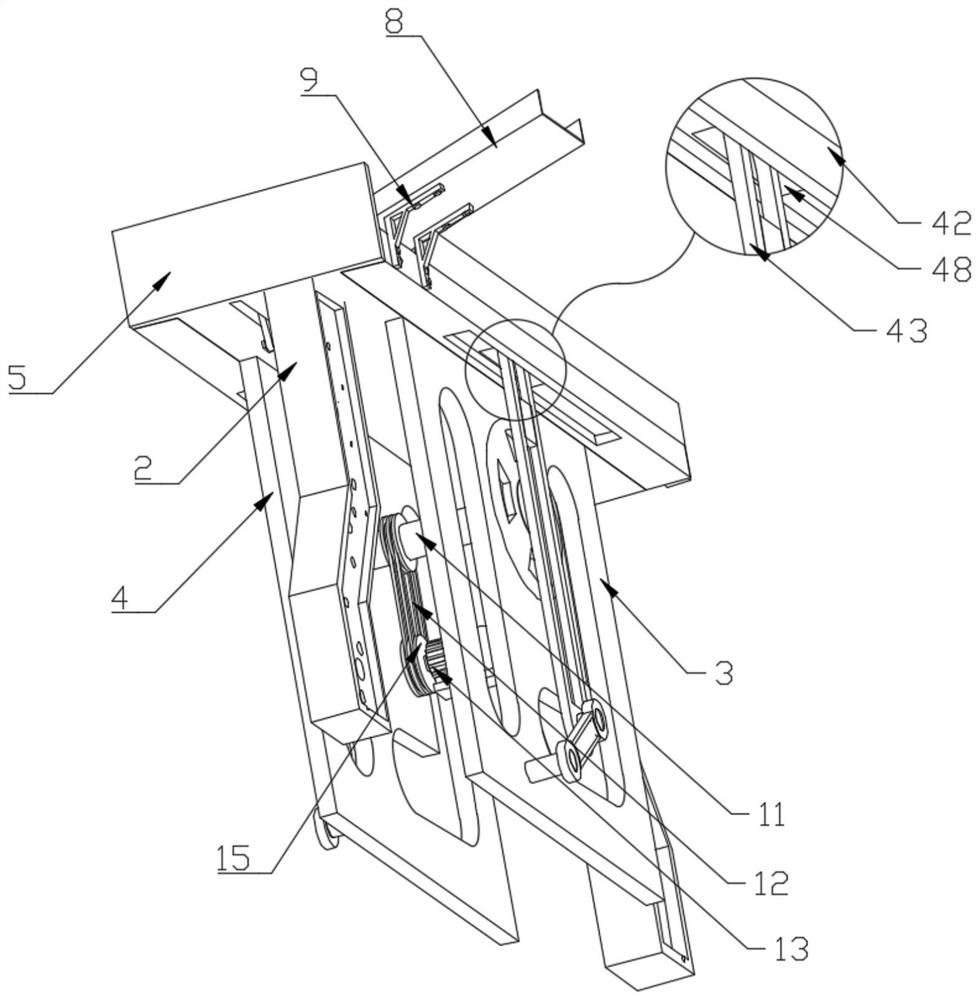

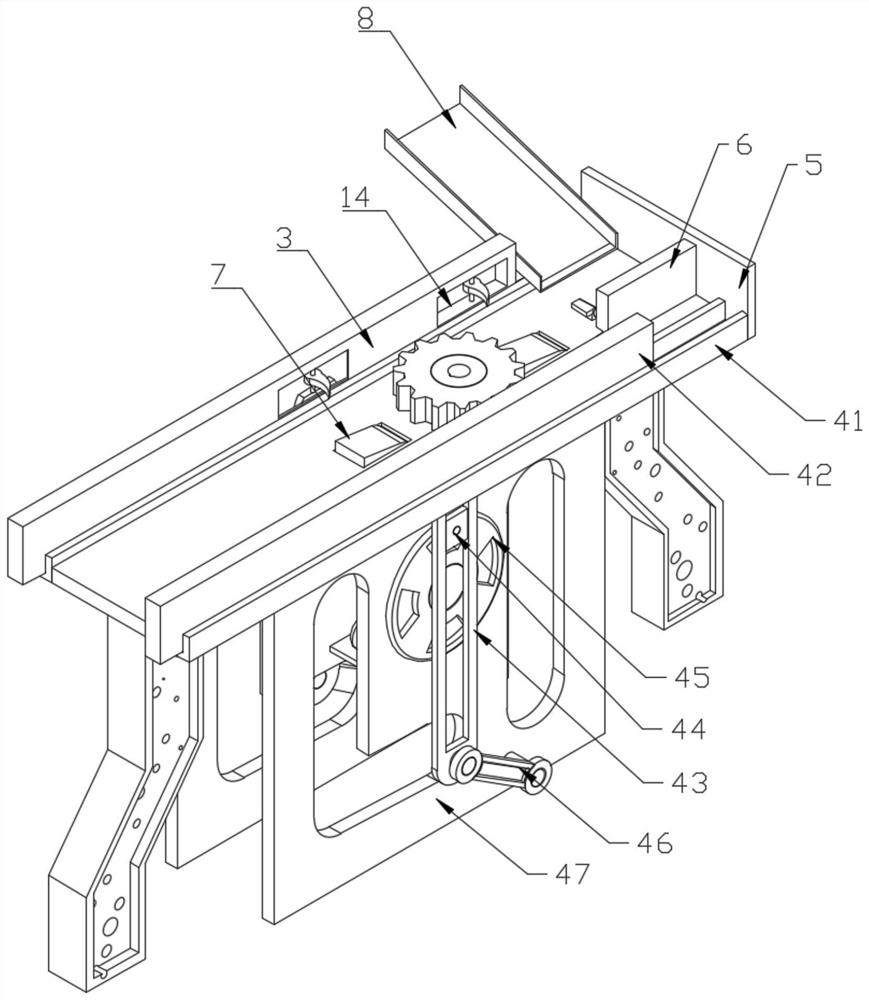

[0039] Please refer to Figure 1 to Figure 10As shown, it shows the specific structure of a preferred embodiment of the present invention, a gear warm precision forging forming conveying equipment, including a precision forging bottom plate 1, and the first drive is fixedly installed on both sides of the precision forging bottom plate 1 Component 3 and the second drive assembly 4, and the support base 2 for the support of precision forging bottom plate 1 is fixedly installed at the bottom of both ends of precision forging bottom plate 1, and an end plate 5 is provided at one end of precision forging bottom plate 1; The inside of the plate 5 is provided with a gear press assembly 6; the gear press assembly 6 is detachably connected to the precision forging base plate 1; above the precision forging base plate 1 is provided with a plurality of gear anti-backward components 7; One side of the gear anti-backward assembly 7 is provided with a gear 10; the side of one end of the prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com