A kind of anti-rolling type semi-rigid inner health water retention material and preparation method thereof

A technology of semi-rigid base layer and water-retaining material, which is applied in the field of road materials, can solve the problems of weakening the performance of semi-rigid base layer, internal curing material maintenance efficiency, premature release of internal moisture, low strength, etc., so as to enhance rigidity, ensure water demand, Chemically stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

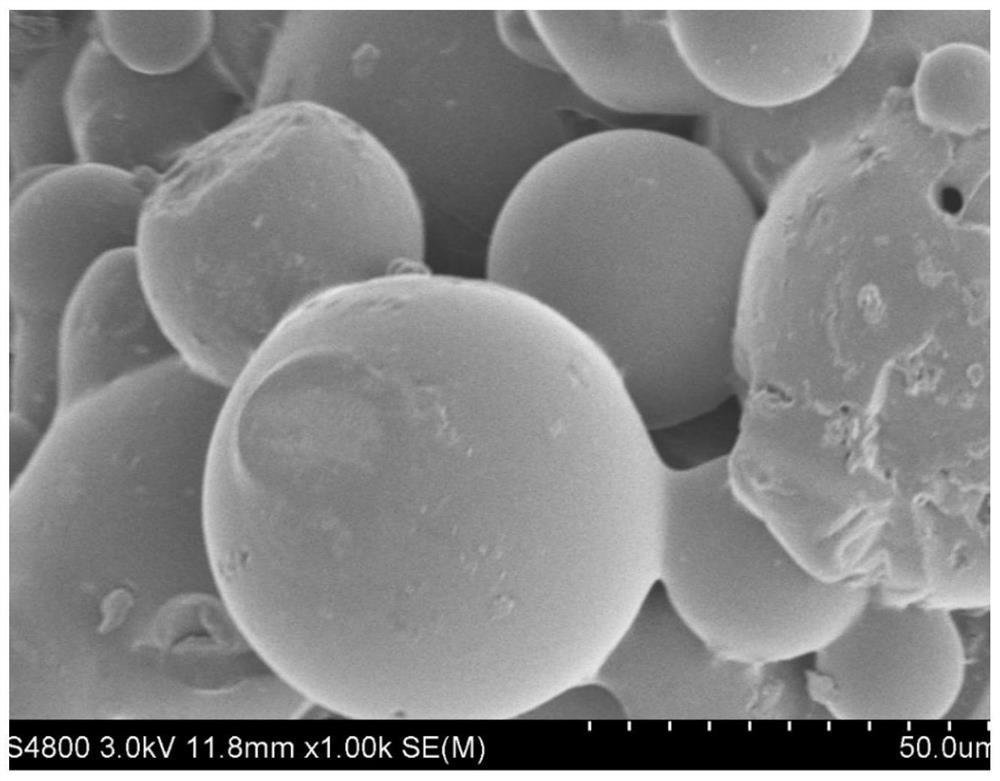

Image

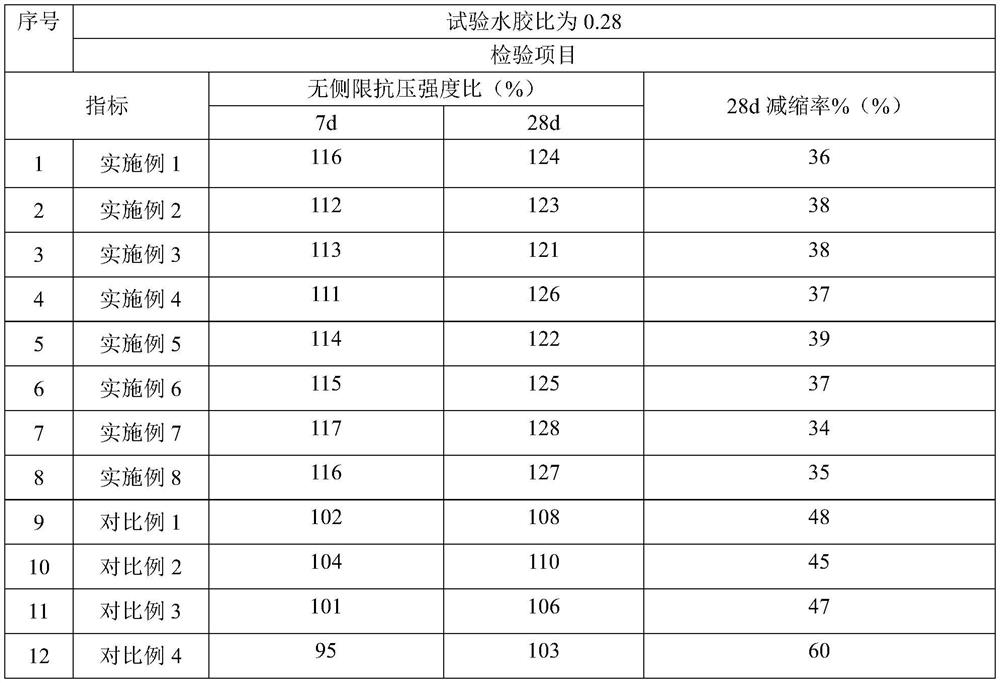

Examples

preparation example Construction

[0047] A preparation method of a rolling-resistant semi-rigid base layer for internal health preservation and water retention, comprising the following steps:

[0048] Step 1: Weigh silica aerogel powder, glass powder, nano-silicon nitride by mass, and mix them evenly for later use;

[0049] Step 2: hydrolyze the silane coupling agent Si-602 under the action of acetic acid, add a certain amount of a mixture of absolute ethanol and deionized water, wherein m 无水乙醇和去离子水 : m 硅烷偶联剂Si-602 = 16:1, v 去离子水 :v 无水乙醇 =7:3, forming a silane coupling agent Si-602 hydrolyzate;

[0050] Step 3: Disperse the uniformly mixed silica aerogel powder, glass powder, and nano-silicon nitride in the hydrolyzed solution of the silane coupling agent Si-602 in Step 2, stir with argon, and then let stand Until the layers are separated, the supernatant liquid is poured out, and the remaining mixture is dried to obtain the modified silica aerogel powder, glass powder, and nano-silicon nitride, which is ...

Embodiment 1

[0062] This example provides a method for preparing an inner-health water-retaining material of a rolling-resistant semi-rigid base, which is composed of the following raw materials in terms of weight:

[0063] 10% silica aerogel powder, 3% glass powder, 5% nano silicon nitride, 2% silane coupling agent Si-602, 1% acetic acid, 27% methacrylic acid, 7% oil phase material, 3% Carrageenan, 16% polyaspartic acid, 20% succinimide, 0.1% 1,4 butanediol diacrylate, 0.2% azobisisobutyronitrile, 0.3% cerium ammonium nitrate, 5.6% sodium ethoxide .

[0064] Among them, in the oil phase material, Span 80 is 4% of the mass fraction of diethyl phthalate.

[0065] In particular, absolute ethanol, deionized water and isopropanol are used as solvents for preparing solutions or washing raw materials, and do not participate in chemical reactions.

[0066] The preparation method of the above-mentioned rolling-resistant semi-rigid base layer of the inner-healthy water-retaining material comprise...

Embodiment 2

[0078] This example provides a method for preparing an inner-health water-retaining material of a rolling-resistant semi-rigid base, which is composed of the following raw materials in terms of weight:

[0079] 10% silica aerogel powder, 3% glass powder, 8% nano silicon nitride, 3% silane coupling agent Si-602, 1.5% acetic acid, 25% methacrylic acid, 8% oil phase material, 3% Carrageenan, 14% polyaspartic acid, 18.82% succinimide, 0.18% 1,4 butanediol diacrylate, 0.2% azobisisobutyronitrile, 0.3% ceric ammonium nitrate, 5% sodium ethoxide .

[0080]In particular, the oil phase material is Span 80 and diethyl phthalate, and Span 80 is 6% of the mass fraction of diethyl phthalate.

[0081] In particular, absolute ethanol, deionized water and isopropanol are used as solvents to prepare solutions or wash raw materials without participating in chemical reactions.

[0082] The preparation method of the above-mentioned rolling-resistant semi-rigid base layer of the inner-healthy wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com