Combined precision seeder

A seeder, a sophisticated technology, applied in agricultural machinery and implements, shovels, plows, etc., can solve the problems of low seeding quality, congestion, complex structure, etc., to improve the uniformity of seed distribution, induce root growth, and reasonable population structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

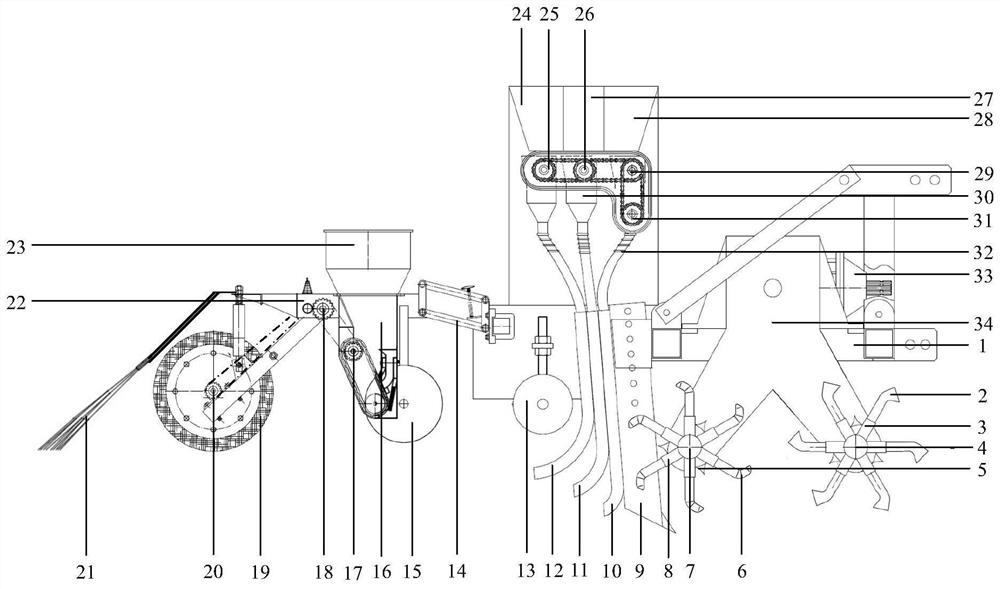

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] As shown in the figure, this embodiment includes a sowing frame and a suspension frame 1, wherein the sowing frame is connected with the suspension frame 1 through a spring bracket and a latch during actual operation.

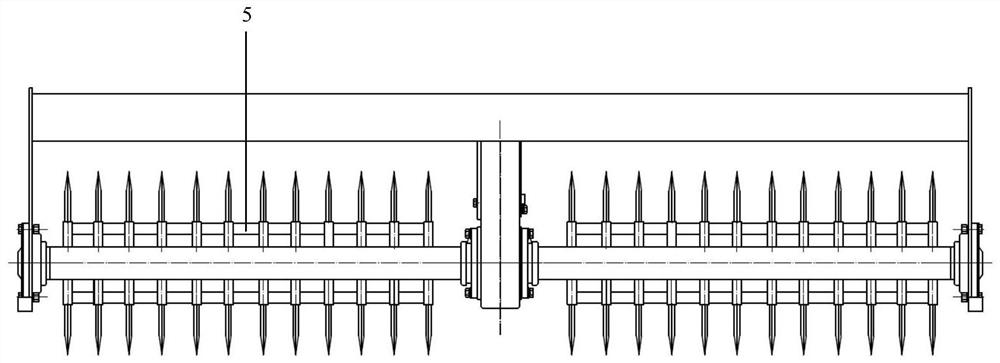

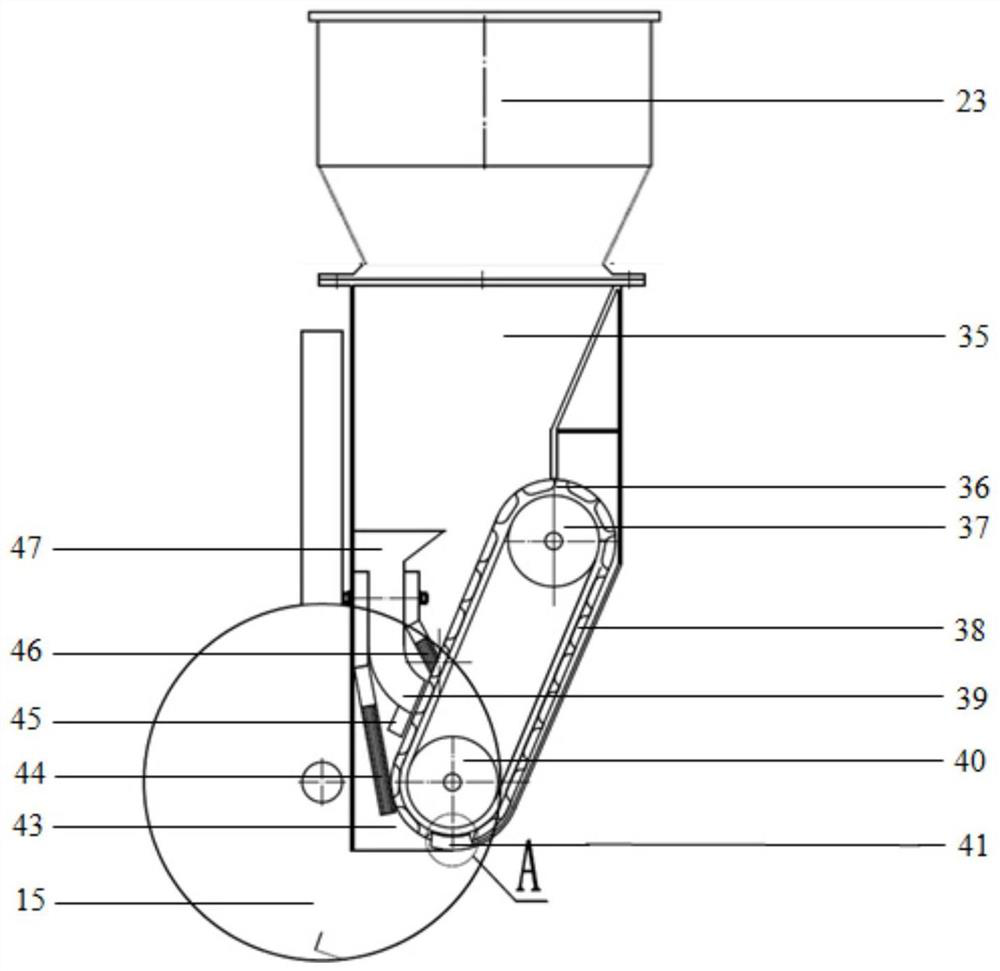

[0028] On the suspension frame 1 of the present embodiment, a recurve chopping knife, a rotary tiller, a subsoiling shovel, a fertilizing mechanism, and a packer are successively installed from front to back: "personnel" are arranged on both sides of the front of the suspension frame. "The shape of the tool magazine installation frame, the two lower ends of the tool magazine installation frame are respectively equipped with a recurve cutter shaft and a rotary tiller shaft, and a recurve cutter shaft is installed at intervals along the length direction of the recurve cutter shaft. Knife magazine 3 is equipped with recurve chop knife blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com