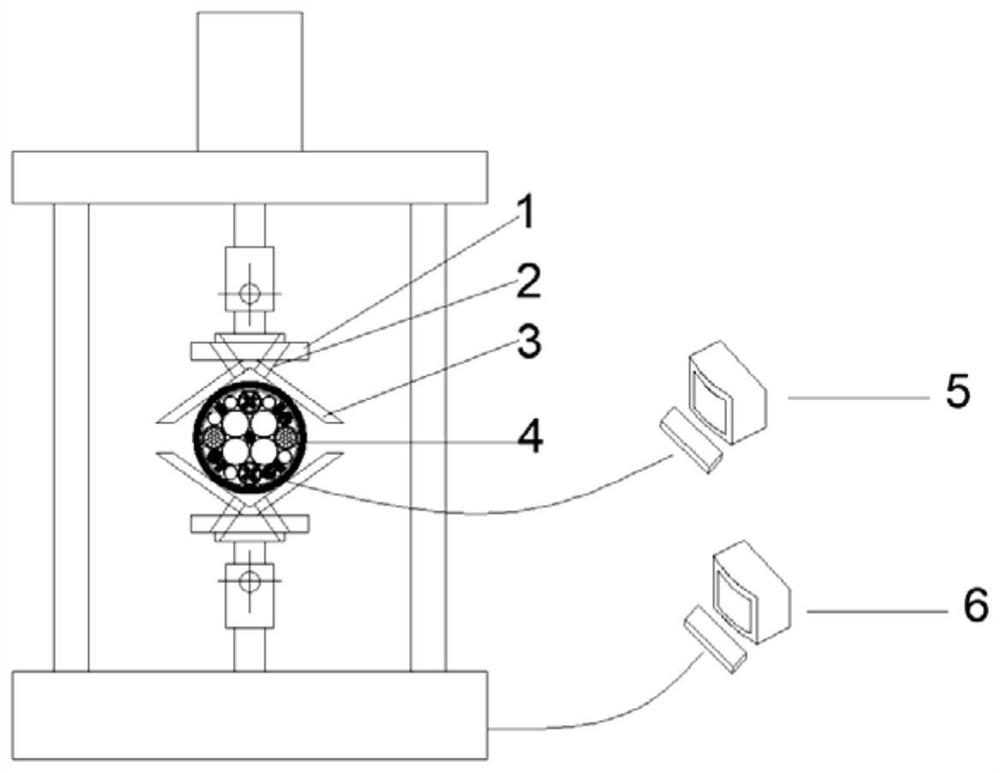

Device and method for testing lateral extrusion capability of umbilical cable

A capability test and umbilical cable technology, applied in the direction of measuring devices, using stable tension/pressure test material strength, instruments, etc., can solve the problems of the test and evaluation system that has not yet formed a system, imperfections, etc., to achieve perfect testing and The effect of evaluation system, easy disassembly and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

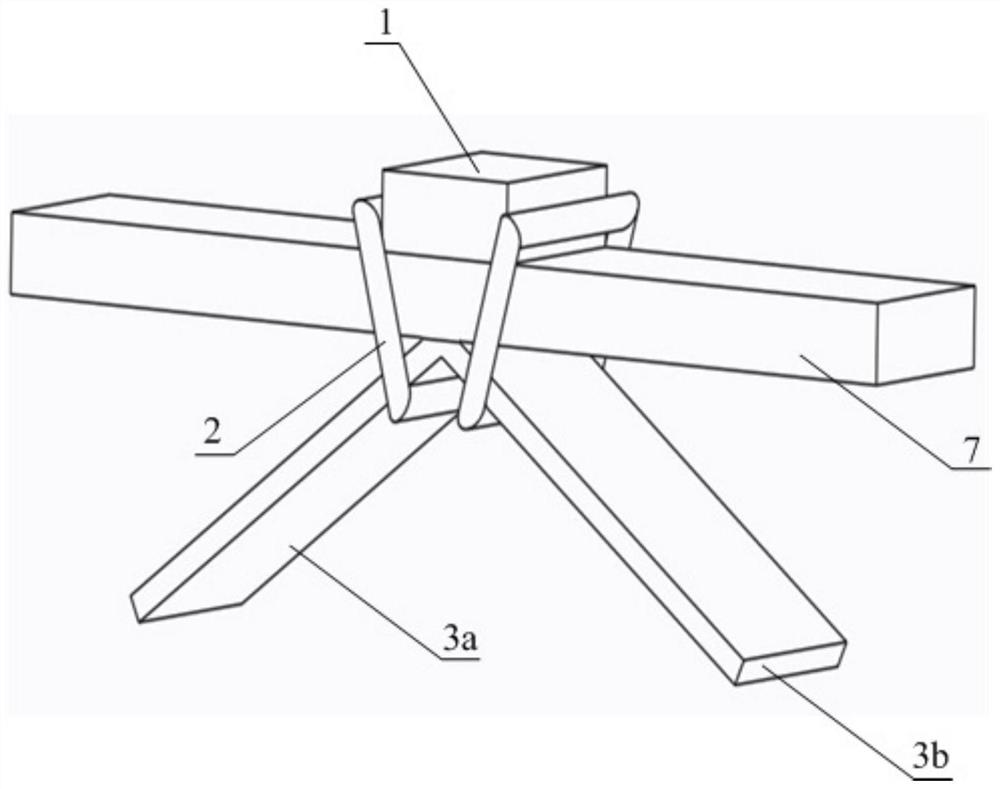

[0044] see Figure 4 Figure 4 It shows the first embodiment of the umbilical lateral extrusion capacity testing method based on the umbilical lateral extrusion capacity testing device of the present invention, including:

[0045] S101, intercept the umbilical cable sample.

[0046] Preferably, the length of the umbilical sample is 200mm-300mm.

[0047] S102. Place the umbilical cable sample on the lower fixture along the horizontal direction.

[0048] It should be noted that when placed, the steel pipe unit in the umbilical sample can be placed close to the contact position between the contact panel and the umbilical sample, or the electrical unit in the umbilical sample can be placed close to the contact position of the umbilical sample to achieve targeted measurement.

[0049] S103, driving the upper clamp to move downward until the upper clamp contacts the umbilical cable sample.

[0050] Specifically, the piston rod of the tensile testing machine can be controlled by...

no. 4 example

[0085] see Figure 7 Figure 7 Shows the fourth embodiment of the umbilical lateral extrusion capacity testing method based on the umbilical lateral extrusion capacity testing device of the present invention, including:

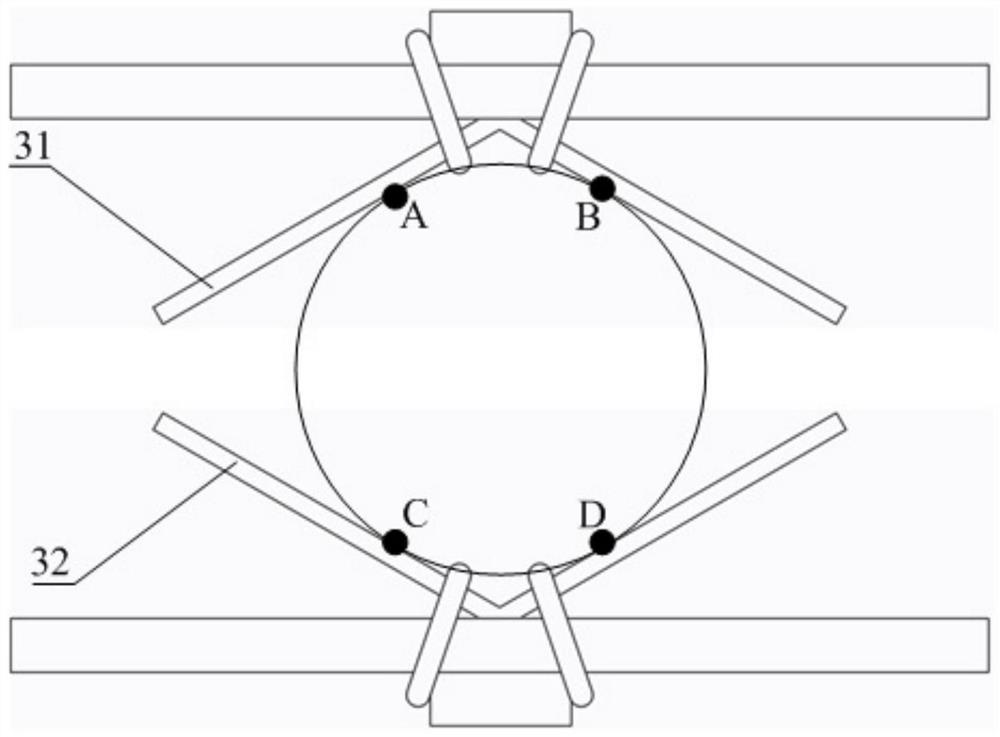

[0086] S401, take four umbilical cable samples with a length of about 200mm-300mm, and draw four straight lines along the axial direction on the outer surface of each umbilical cable sample as marking lines (including two upper marking lines A, B and two lower marking lines) Marking lines C, D, see figure 2 ) to indicate where to load.

[0087] S402. Place the umbilical cable samples horizontally on the "V"-shaped lower clamp, and keep the lower marking line in contact with the lower clamp.

[0088] S403, gradually lower the hydraulic cylinder of the tensile testing machine to keep the umbilical cable sample in contact with the upper fixture.

[0089] S404, start loading, and record the "displacement-force" curve. Wherein, the initial loading speed is l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com