Debris treatment device of machine tool

A technology for processing equipment and debris, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, manufacturing tools, etc., can solve the problems that debris is easy to fall off, cannot be collected and pressed metal ingots, etc., to prevent debris from falling off, The nesting process is convenient and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

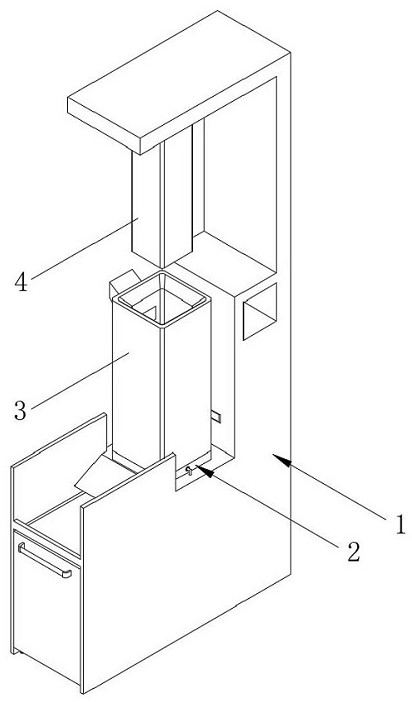

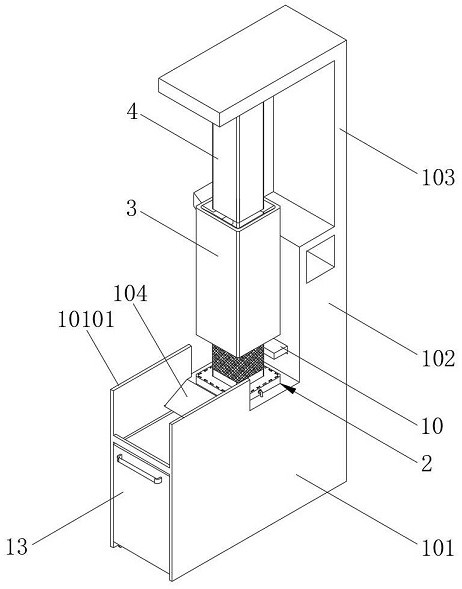

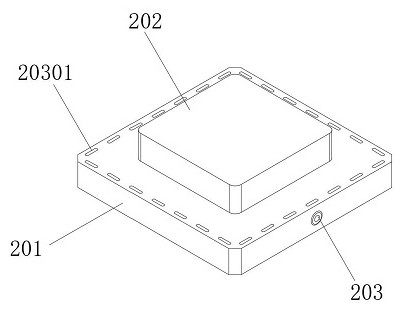

[0036] In order to achieve automated pressing metal spindle flow, the present invention provides figure 1 , figure 2 , Figure 4 , Figure 5 with Image 6 The debris treatment apparatus of a machine, including a device assembly 1 as a body structure and is provided by the pressing base 2, an adjustable die-casting mode 3, and a lower pressure mold 4;

[0037] The apparatus assembly includes a hollow base case 101, a power cartridge 102 disposed above the base case 101 and a bending plate 103 disposed above the power tank 102, and the upper end surface of the base case 101 is formed. 2 fixed The plane of the assembly is provided with the drive adjustable die-casting moving mode 3 along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com