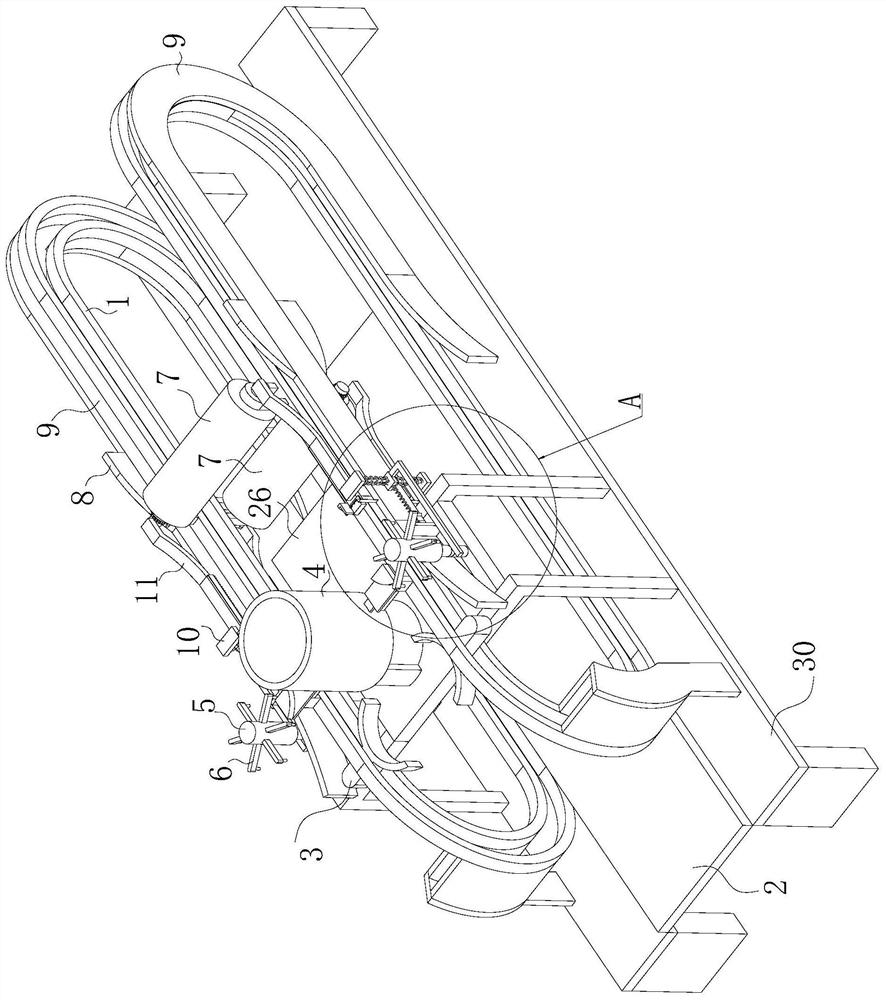

Full-automatic plane up-down labeling machine

A labeling machine, fully automatic technology, applied in the direction of labeling machine, labeling, packaging, etc., can solve the problems of difficulty in ensuring accuracy, low efficiency, uneven labeling, etc., to ensure stability and accuracy, save handling time, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

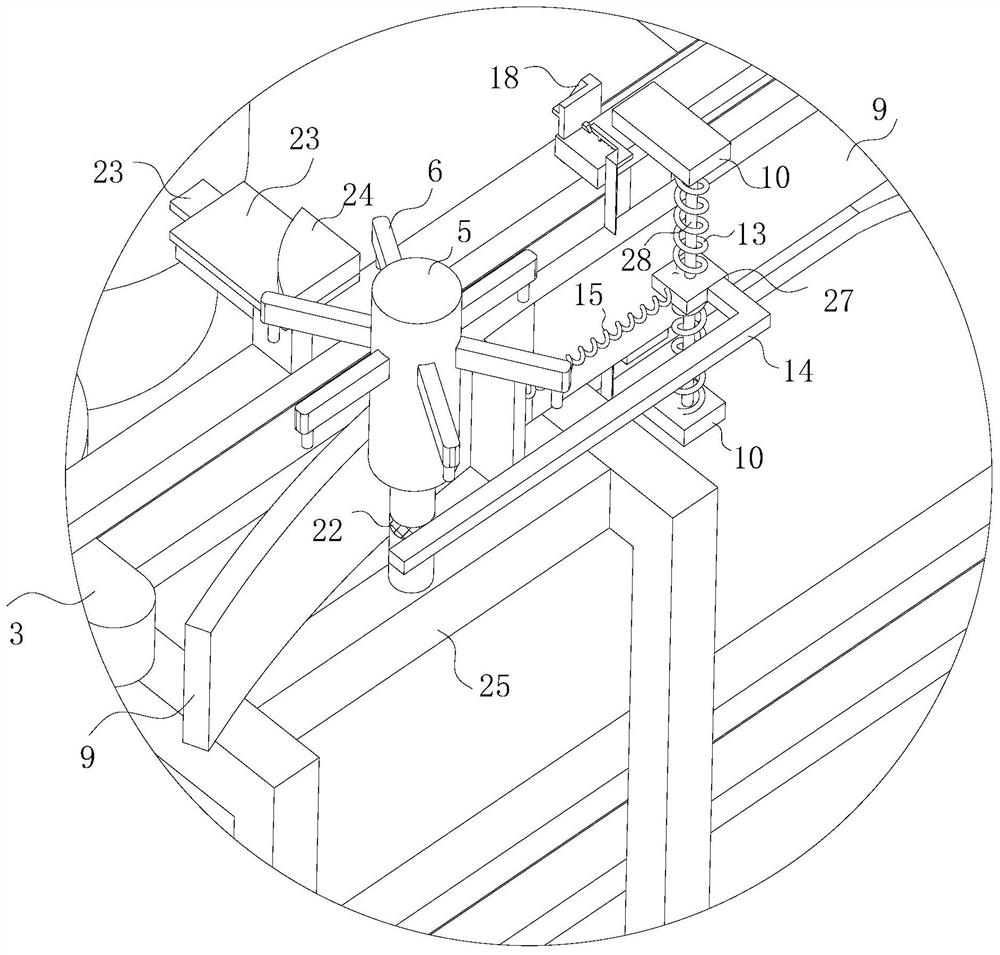

[0030] see Figure 1-8 , the present invention provides a technical solution: a fully automatic plane up and down labeling machine, including a track 1, which is provided with a retrieving mechanism for grabbing and clamping workpieces, and is fixedly connected between the two tracks 1 for The feeding pipe 4 is connected with two labeling rollers 7 vertically and elastically slidingly on the track 1, and the track 1 is provided with a labeling mechanism for driving the two labeling rollers 7 to move inward synchronously to label the workpiece; A supporting plate 26 for supporting workpieces is arranged below the material pipe 4, and a feeding mechanism that cooperates with the labeling mechanism to control the feeding of the feeding pipe 4 is provided on the supporting plate 26.

[0031] The retrieving mechanism includes claws 3, which are horizontally slidably connected in the track 1, and the track 1 is fixedly connected with a baffle 9 for limiting the claws 3, and the baff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com