Integral type bonding plate of aircraft system label

An aircraft system, integrated technology, applied in the directions of stamps, instruments, identification devices, etc., can solve the problems of difficult storage, large installation workload, cumbersome installation, etc., to improve efficiency, improve adhesion, and facilitate management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

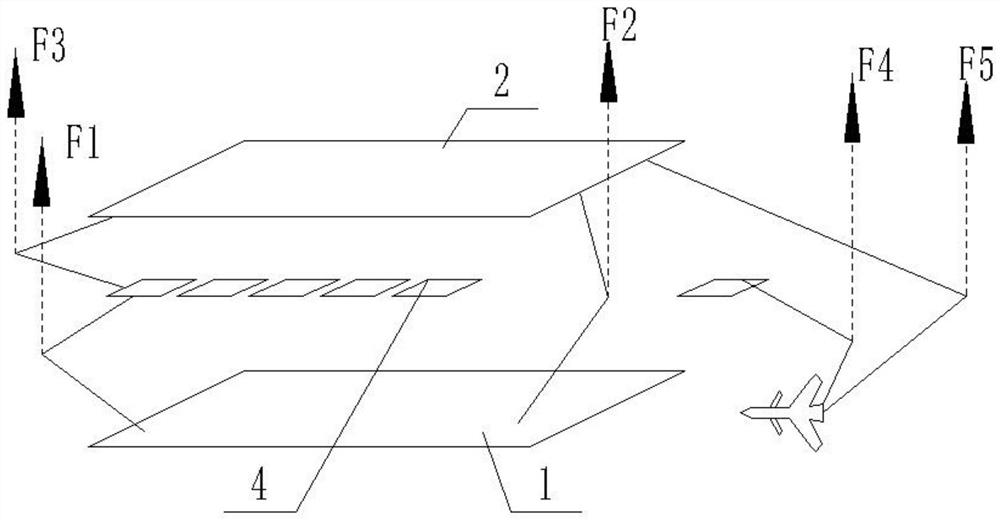

[0039] An aircraft system signage integral adhesive panel such as figure 1 and Figure 6 As shown, it includes release paper 1, transfer film 2, and component label layer 3. The component label layer 3 is arranged between the release paper 1 and the transfer film 2 .

[0040] The release paper 1 is the carrier of the entire bonding board. The release paper is composed of three layers, the first layer of backing paper; the second layer of coating; the third layer is an anti-adhesive substance, generally silicone oil.

[0041] The transfer film 2 includes a waterproof surface and an adhesive surface, and the adhesive surface is bonded to the release paper 1 . The waterproof surface is mainly the main body of the transfer film 2, which has certain strength, water resistance, moisture resistance and high temperature resistance. The adhesive surface is a PE micro-adhesive film, and the peeling strength with the release paper 1 is the fourth peeling strength F2.

[0042] The par...

Embodiment 2

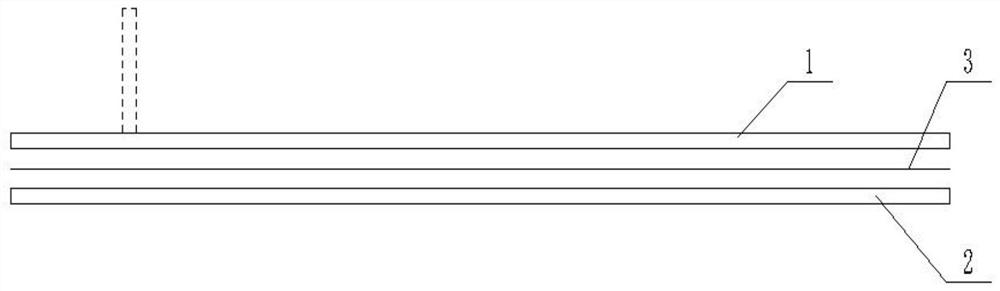

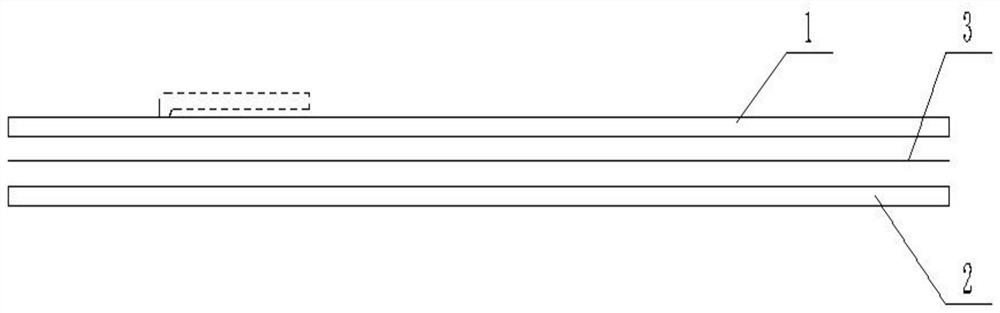

[0054] An aircraft system signage integral adhesive panel such as Figure 7 and Figure 8As shown, on the basis of Embodiment 1, an easy-tear line 201 is added on the transfer film 2, and there are two ways to set the easy-tear line 201 .

[0055] One of the easy-to-tear lines 201 is set between two adjacent columns of part labels 4, and a row of transfer film 2 with part labels 4 is torn off from the whole to form a new whole as a row of part labels 4 and transfer film 2 . The setting of the easy-to-tear line 201 is convenient for handling and sticking during the labeling process, and is convenient for sticking at narrow positions of the body.

[0056] The other type of easy-tear line 201 is vertically intersecting along the length and width of the transfer film 2 , and the easy-tear line 201 is set between two adjacent component labels 4 . The vertically intersecting easy-tear lines 201 have a relatively large mutual pulling force at the intersection, and when the transfe...

Embodiment 3

[0058] A method for using an aircraft system signage integral adhesive plate, the method comprising the following steps:

[0059] (1) Take out the release paper 1 with the transfer film 2 and the parts label 4, separate the transfer film 2 from the release paper 1, and form the bonding whole with the transfer film 2 and the parts label 4;

[0060] (2) The bonding surface of the transfer film 2 is pasted on the aircraft surface, and now the adhesive layer 404 of the parts label 4 is also bonded to the aircraft surface; the transfer film 2 is torn off, and the transfer film 2 is separated from the parts label 4 to achieve Aircraft integrated fast labeling.

[0061] The specific usage steps are:

[0062] ① Check whether the signage parts in the integral bonding plate meet the requirements, and whether there is any blistering and debonding at the signage;

[0063] ②Take out the whole bonding board, and spread it on a clean and flat operating table according to the position where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com