Automatic tsa label labeling machine

A labeling and fully automatic technology, applied in the field of fully automatic TSA label labeling machine, can solve the problems of increased working hours, insufficient pressing time, disconnected process, etc., and achieve the effect of improved firmness, fast labeling speed and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in further detail below in conjunction with the examples and the accompanying drawings, but the implementation of the present invention is not limited thereto.

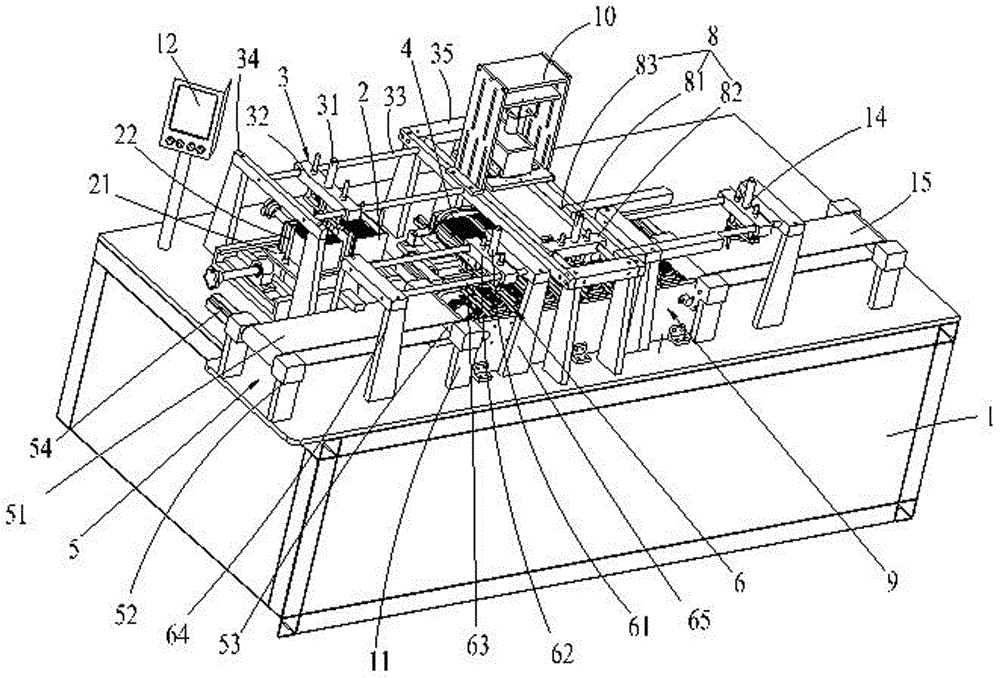

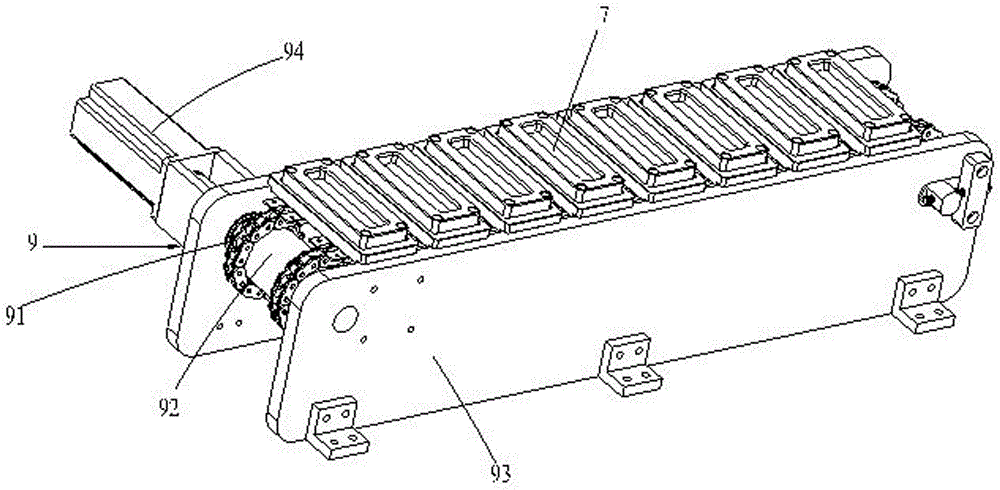

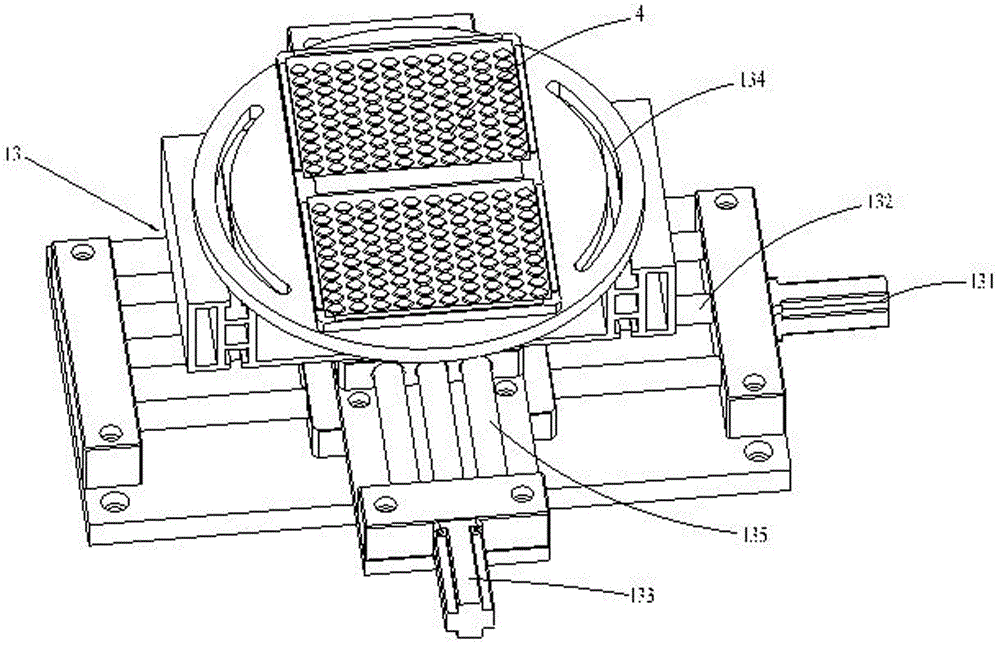

[0061] Such as Figure 1 to Figure 3 As shown, the fully automatic TSA label labeling machine provided by the present invention includes a frame 1 and a label storage box 2 respectively arranged on the frame 1, a label suction cup assembly 3, a label adsorption and detection platform 4, and a product placement conveyor belt 5 , product suction cup assembly 6, product positioning fixture assembly 7, labeling suction cup assembly 8, product fixture transmission system 9, first vision system 10 and second vision system; wherein, a certain amount ( For example, 100 TSA labels, the number of labels on each TSA label is 100. Standard storage box 2 is cuboid, and it is made up of four side plates and a bottom plate.

[0062] The label sucker assembly 3 is used to suck the labe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com