Bilateral consequent pole type hybrid excitation brushless motor

A hybrid excitation and brushless motor technology, applied in the direction of motors, magnetic circuits, electric components, etc., can solve the problems of motor output capacity and magnetic adjustment capacity constraints, to improve torque density and power density, enhance magnetic field modulation effect, Effect of reducing the risk of irreversible demagnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Example 1 Inner rotor, with three-phase m=3, Ns=6 (k=2), p a = 2,p s =12,p r =10 as an example

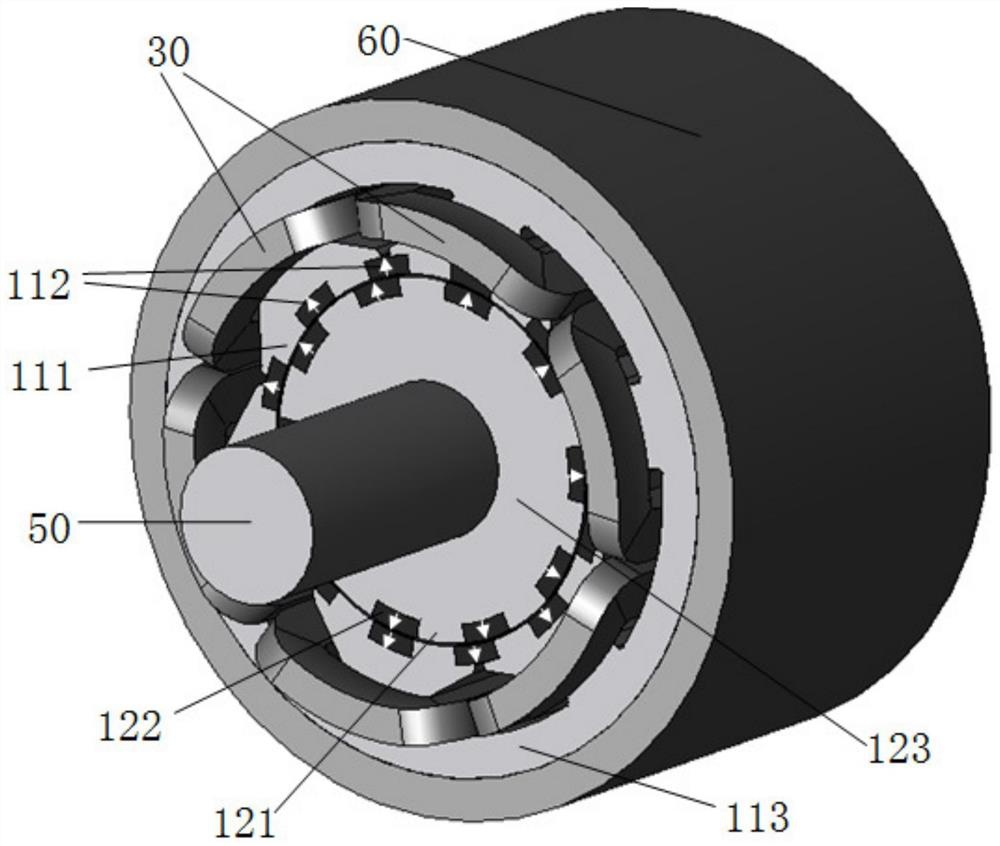

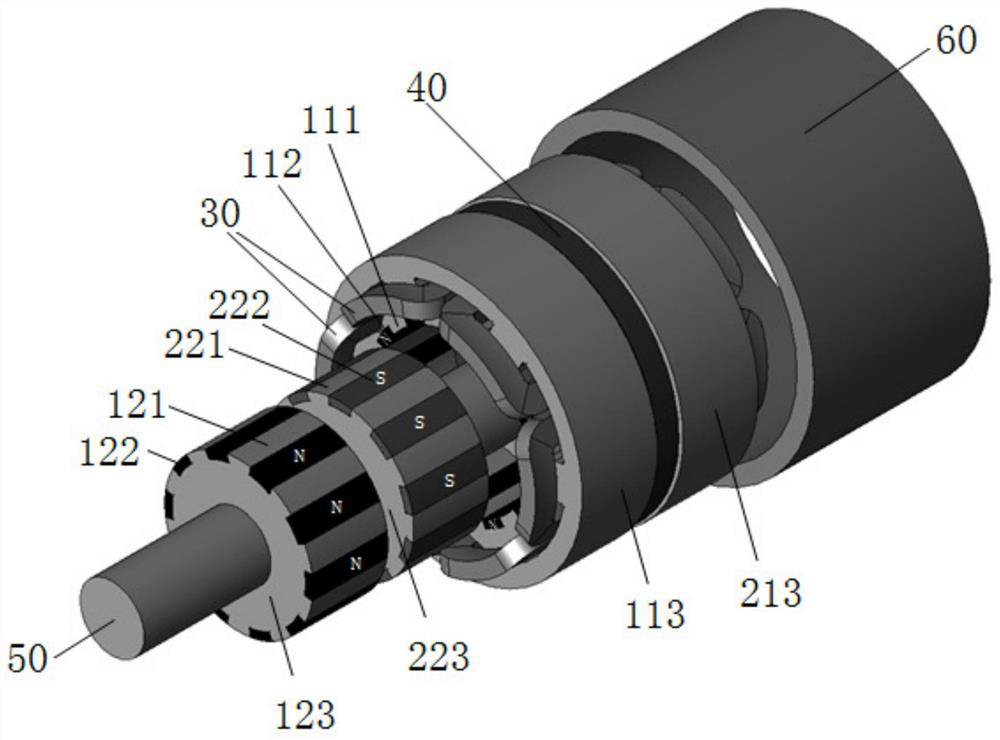

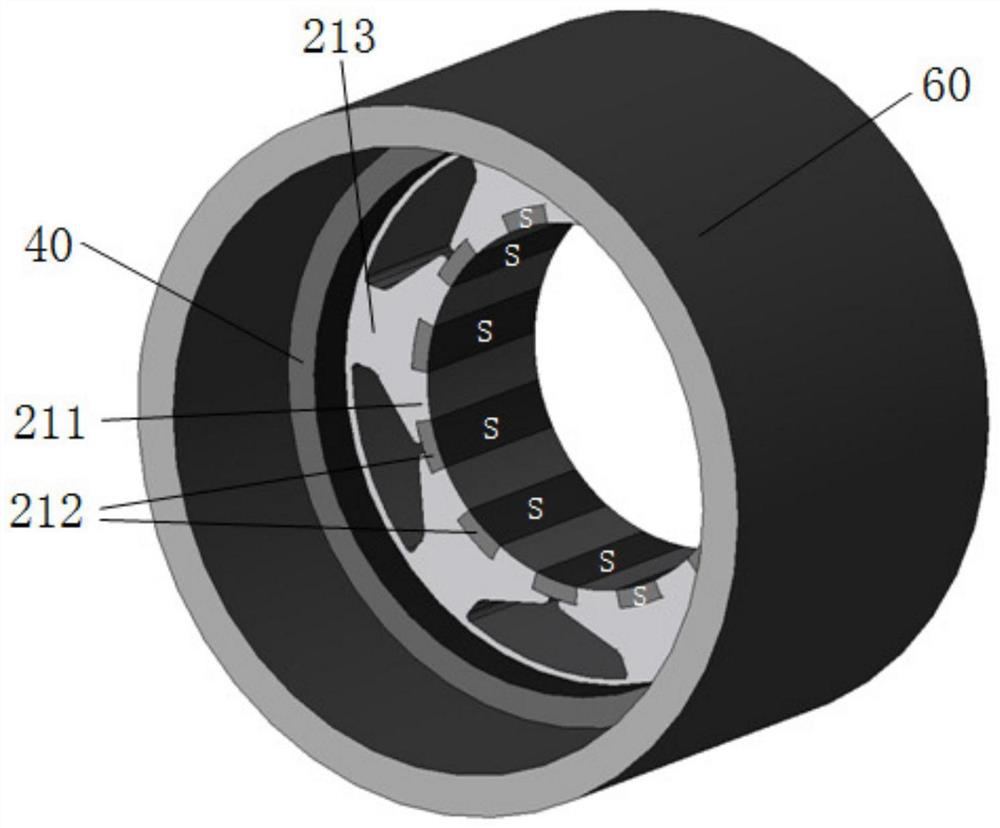

[0068] like Figure 1 to Figure 6 As shown, a bilateral alternating pole hybrid excitation brushless motor includes a stator and rotor 10 , a stator and rotor 2 20 , an armature winding 30 , an annular DC excitation winding 40 , a rotating shaft 50 and a casing 60 .

[0069] The above-mentioned casing is set on the outer circumference of the first stator and rotor and the second stator and the rotor, and the casing is made of magnetically conductive or non-magnetic material; when the casing is made of nonmagnetic material, there is still a A solid magnetically permeable yoke is provided.

[0070] The stator-rotor 1 and the stator-rotor 2 are arranged parallel to each other along the axial direction of the rotating shaft, wherein the rotating shaft is made of magnetically conductive material.

[0071] Stator-rotor-1 includes stator-11, rotor-12 and an air gap between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com