Five-phase axial magnetic flux permanent magnet motor for electric vehicle

A technology for axial flux and electric vehicles, applied in electric vehicles, motors, electric components, etc. Low efficiency and other problems, to achieve the effect of shortening the main magnetic circuit, meeting the low-speed high-torque capability, wide speed range, and high magnetic modulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] The invention relates to a five-phase axial flux permanent magnet motor used for electric vehicles.

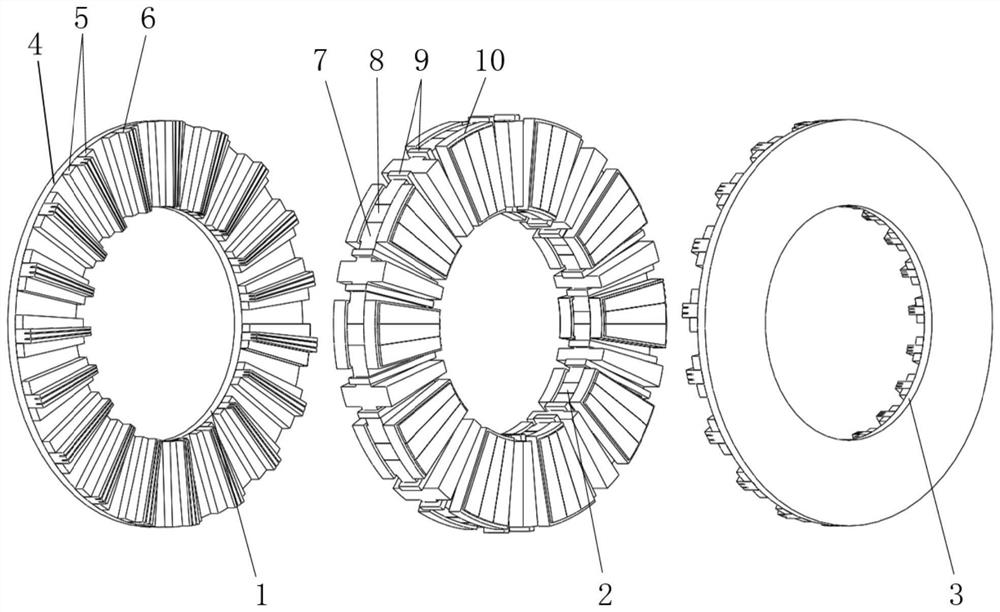

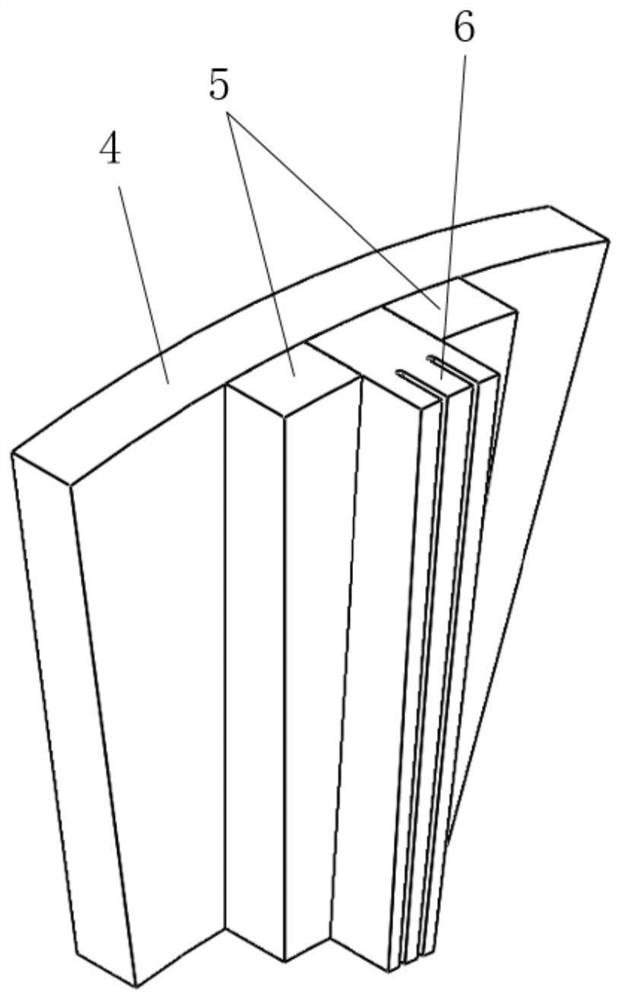

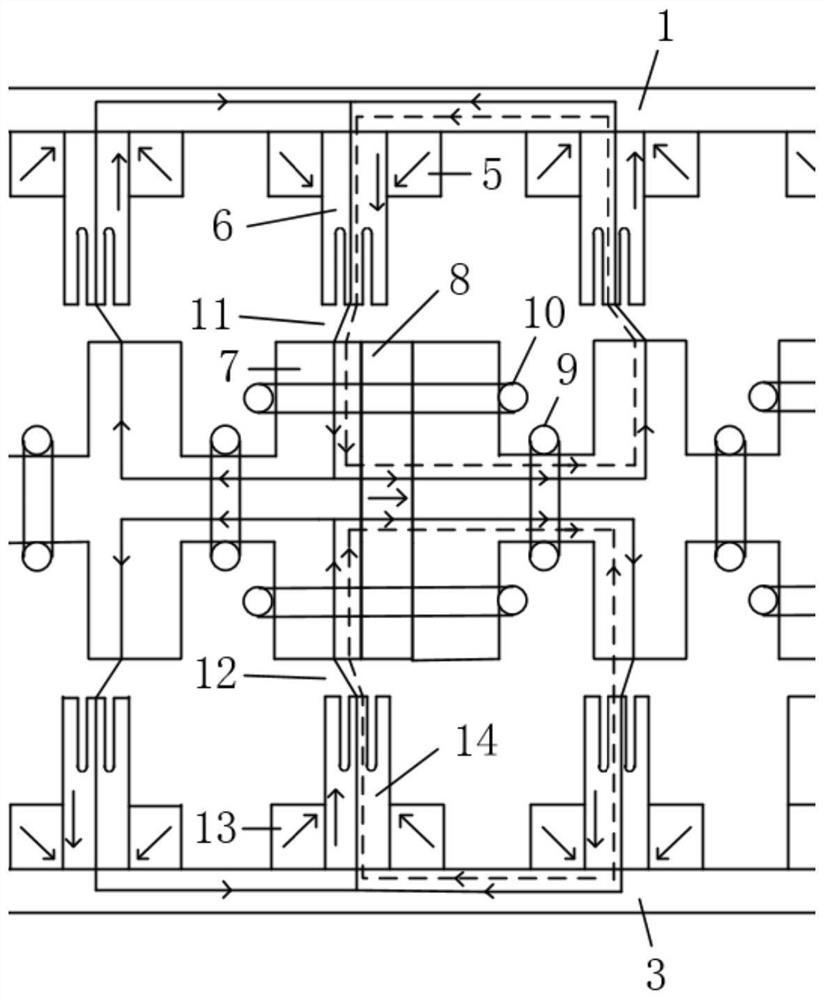

[0030] like figure 1 As shown, the dual-rotor / single-stator axial topology is adopted, including the first rotor 1, the stator 2, and the second rotor 3 installed coaxially in sequence; Air gap, the first rotor 1 and the second rotor 3 are symmetrical about the center of the stator 2, each rotor includes a magnetically conductive annular back iron 4, and nineteen modular rotor poles are arranged on the annular back iron 4, each modular The rotor pole consists of two small NdFeB permanent magnets 5 and one large NdFeB permanent magnet 6, the large NdFeB permanent magnet 6 is sandwiched between the two small NdFeB permanent magnets 5; the large NdFeB permanent magnet The axial length of 6 is greater than the small NdFeB permanent magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com