Manufacturing method of display module and related product

A technology of display module and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, instruments, electrical components, etc., can solve the problems of light leakage of flexible display panels and poor imaging effect of front camera, so as to improve the user experience and solve the problems of light leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

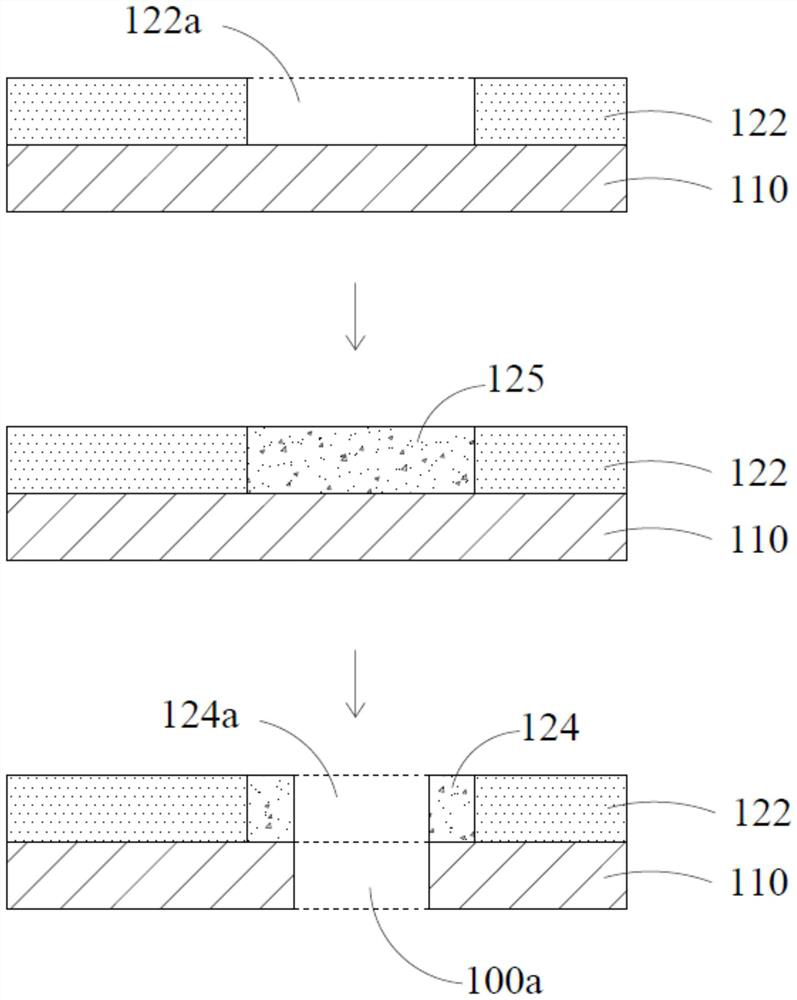

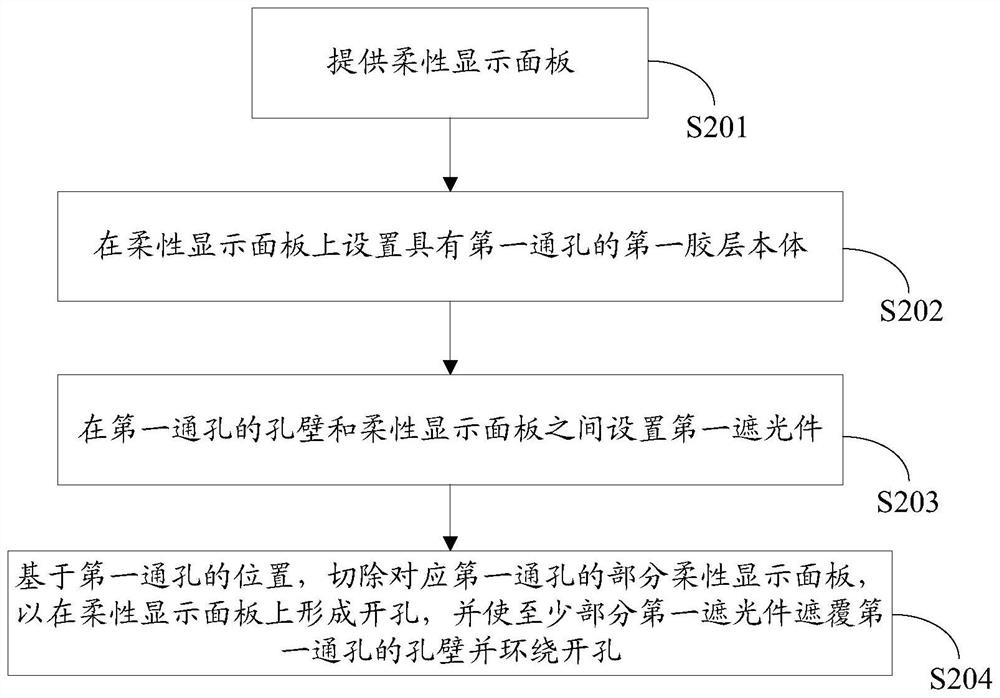

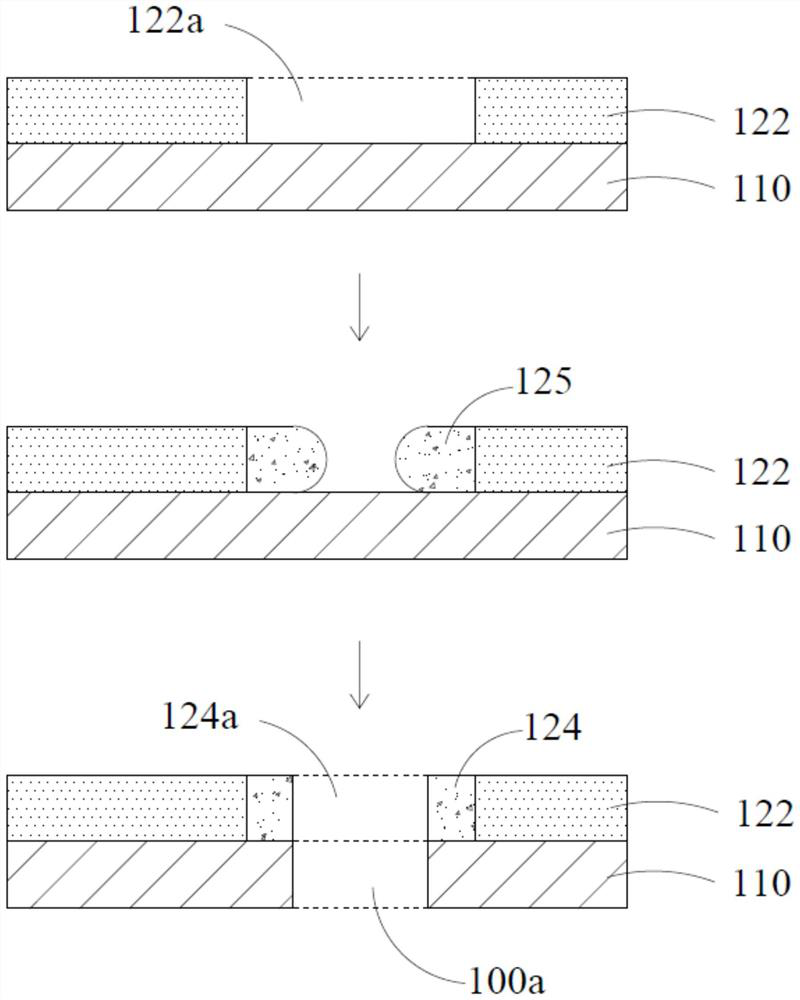

[0075] The following will clearly and completely describe the technical solutions in the embodiments of the present application with reference to the accompanying drawings in the embodiments of the present application.

[0076] In normal touch mobile phones, in order to meet the needs of users, a large-sized display panel is usually configured. The display panel is used as a display module together with related touch components. When the display panel is a liquid crystal display panel, since the liquid crystal display panel cannot emit light, it is also necessary to configure a backlight assembly to provide a light source for the liquid crystal display panel. However, the large size of the liquid crystal display panel and the backlight assembly is not conducive to the design of the mobile phone. Therefore, some mobile phones will choose flexible self-luminous display panels that can emit light to replace liquid crystal display panels and backlight components. Wherein, the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com