Isolation material, method for preparing same, display panel and display device

A technology for display panels and spacers, applied in nonlinear optics, instruments, optics, etc., can solve the problems of poolingmura light leakage, large spacer compression, etc., to improve supporting force, small compression, and solve light leakage. effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

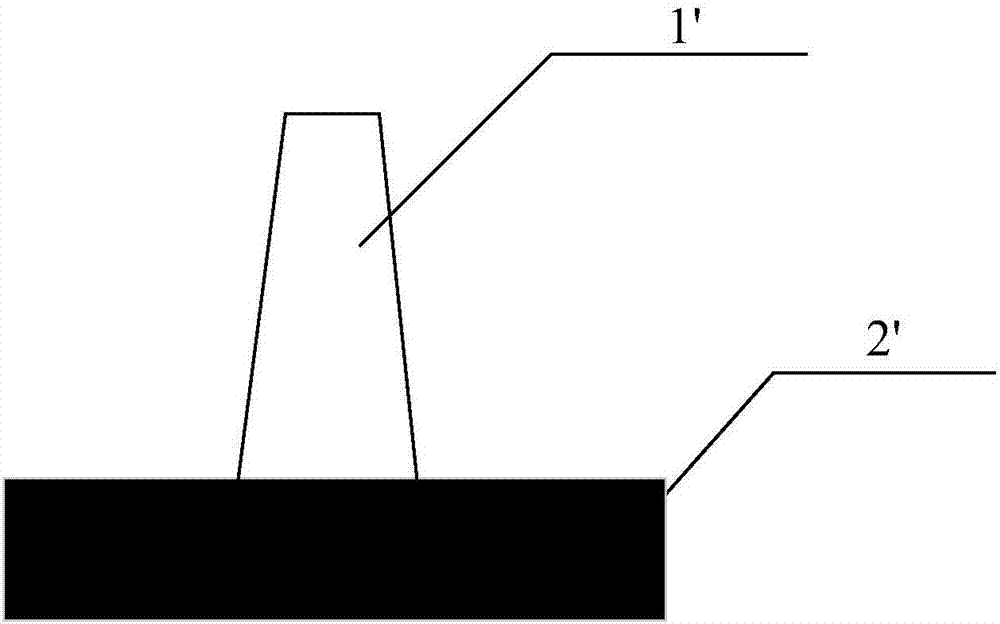

[0035] refer to Figure 4 , is a structural schematic diagram of a spacer according to an embodiment of the present invention.

[0036] The spacer is disposed between the first substrate and the second substrate of the display panel, and is formed on the black matrix 2 of the first substrate. The spacer includes a first component 101 and a second component 102 .

[0037] The first part 101 is formed on the black matrix 2, the first part 101 has two opposite first end faces and second end faces, and the first end face of the first part 101 is bonded to the black matrix 2, the first part 101 of the first part 101 The area boundary of one end surface coincides with the area boundary of the black matrix 2 where it is bonded, and the area of the second end surface of the first component 101 is not larger than the area of the first end surface;

[0038] The second part 102 is formed on the second end face of the first part 101, the second part 102 has a third end face and a fou...

Embodiment 2

[0047] refer to Figure 7 , is a flowchart of a method for preparing a spacer according to an embodiment of the present invention.

[0048] Step 1, forming the first part of the spacer on the black matrix of the first substrate through the first patterning process.

[0049] The first component has opposite first end surfaces and second end surfaces, and the first end surfaces of the first components are bonded to the black matrix.

[0050] Specifically include the following processes:

[0051] forming a photoresist layer for making the first component on the black matrix of the first substrate;

[0052] The photoresist layer is exposed and developed by using the first mask to form the first component on the black matrix of the first substrate, wherein the first mask is a mask for making the black matrix on the first substrate.

[0053] In this way, the mask plate of the black matrix is used to expose and develop the photoresist layer of the first part to make the first pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com