Automatic smoothing device applied to flexible OLED display screen

A display screen, flexible technology, applied in conveyor control devices, transportation and packaging, furnaces, etc., can solve the problems of low degree of automation, wrinkles, increase product defect rate, etc., to achieve good stability, high degree of automation, versatility strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

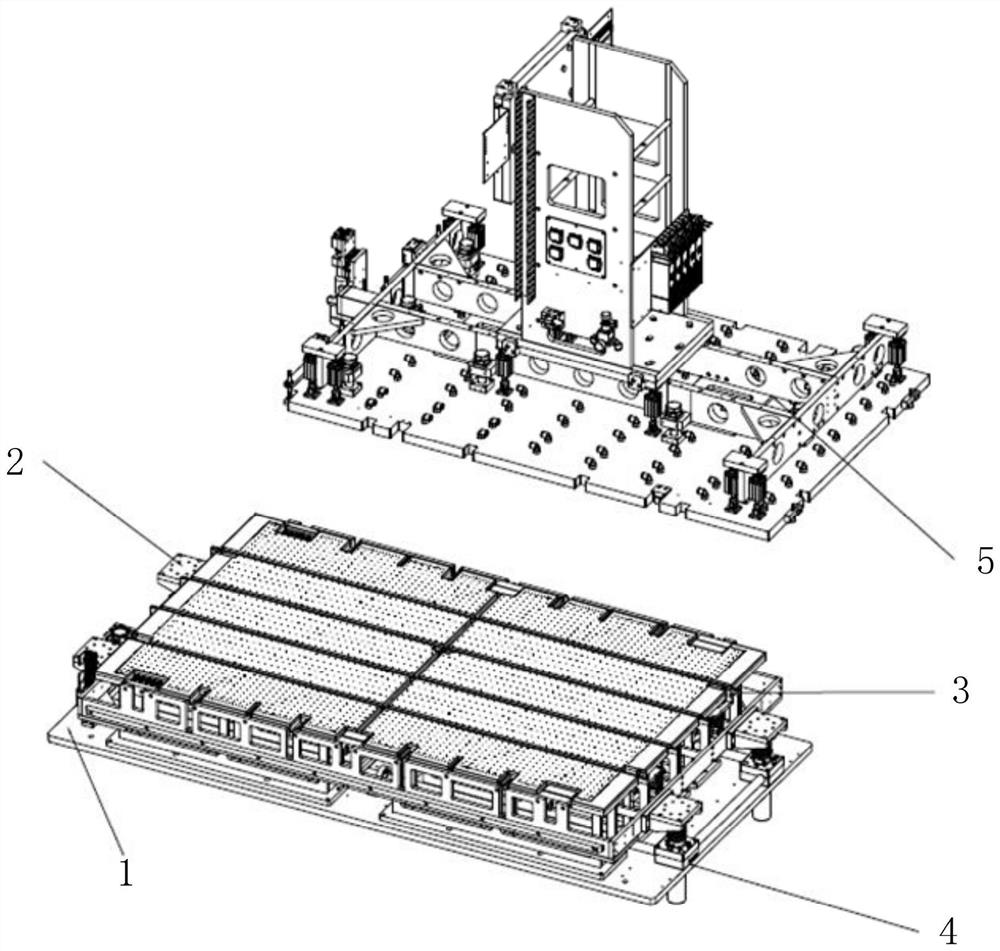

[0049] like Figure 1 to Figure 7 as shown,

[0050] An automatic smoothing device applied to flexible OLED displays, comprising a vacuum adsorption stage mechanism 1, a material receiving and lifting mechanism 2, a synchronous movement mechanism 4 and a transport mechanism 5, and the synchronous movement mechanism 4 is installed on the vacuum adsorption stage mechanism 1 , the material receiving and lifting mechanism 2 is installed on the vacuum adsorption platform mechanism 1 below through the synchronous motion mechanism 4, and the driving ends around the top of the synchronous motion mechanism 4 are connected with the material receiving and lifting mechanism 2 above. The upper position of the vacuum adsorption stage mechanism 1;

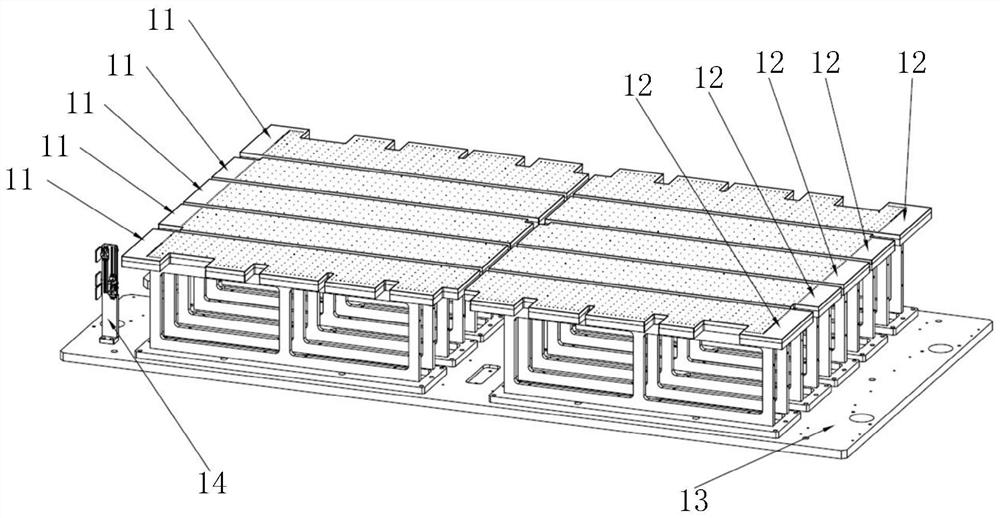

[0051] The vacuum adsorption stage mechanism 1 includes a bottom plate 13, and the top of the bottom plate 13 is provided with a vacuum stage unit;

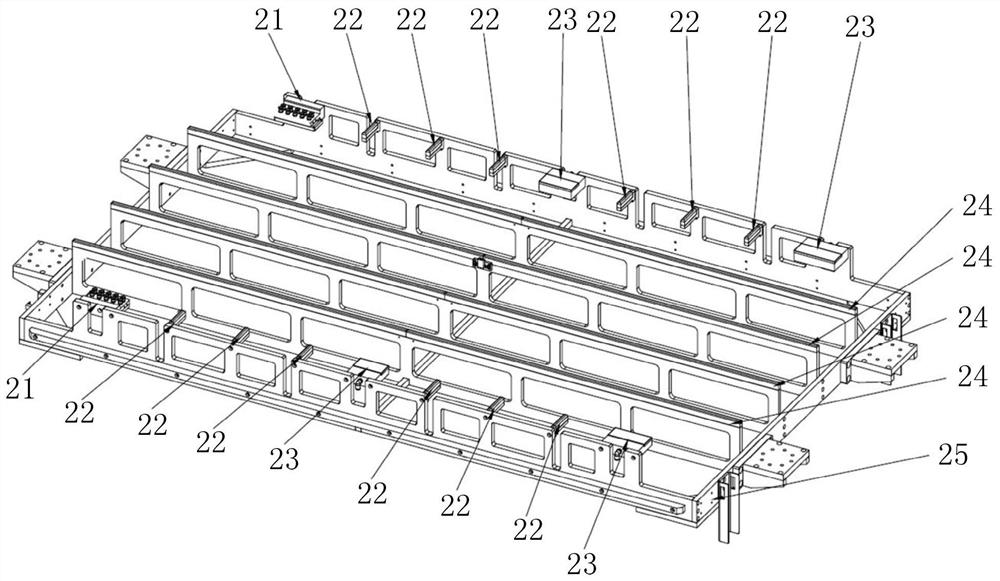

[0052] The material-receiving lifting mechanism 2 includes a lifting frame 25, and the driving...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap