Method and apparatus for manufacturing workpiece into product

A technology for workpieces, products, applied in the field of faceted diamonds or other faceted gemstones, which can solve problems such as no fully automatic process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

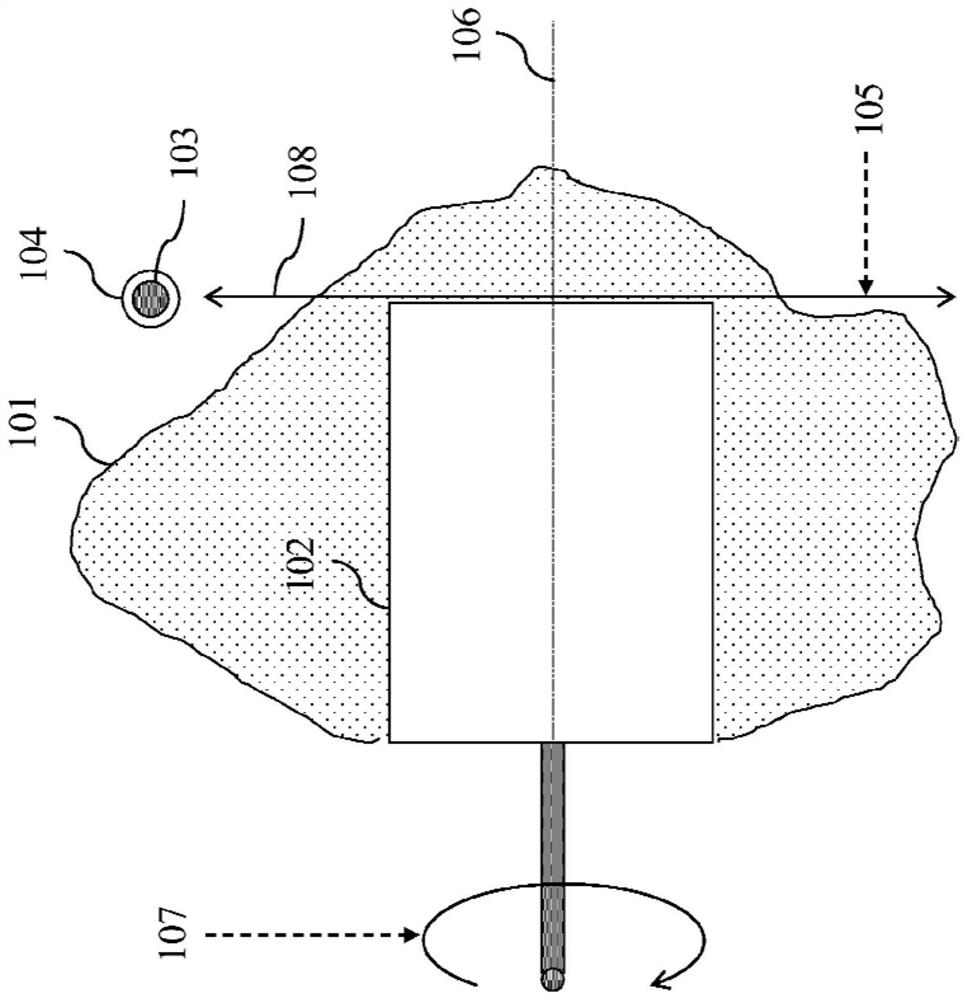

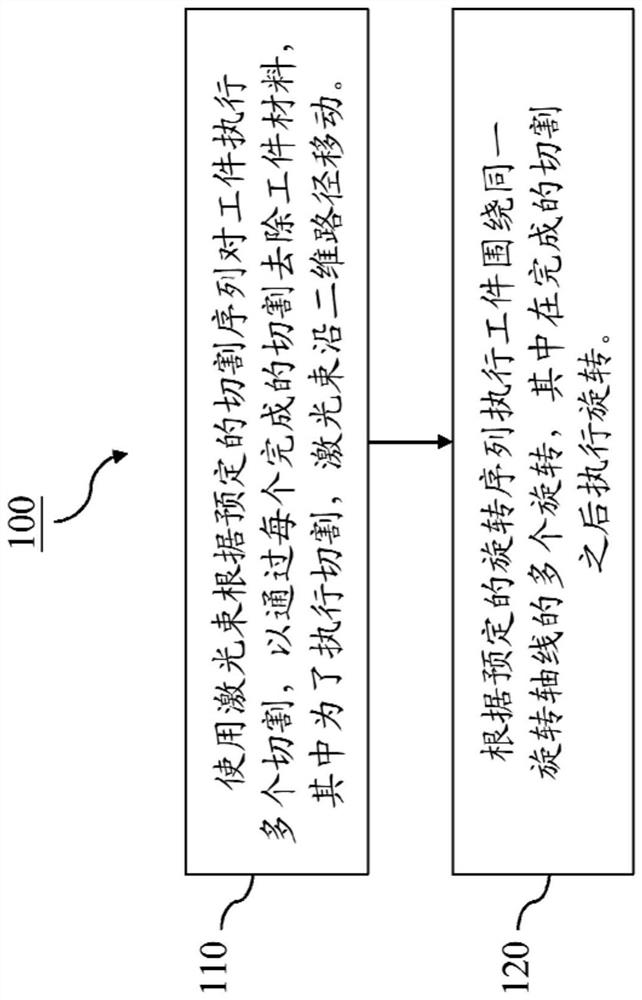

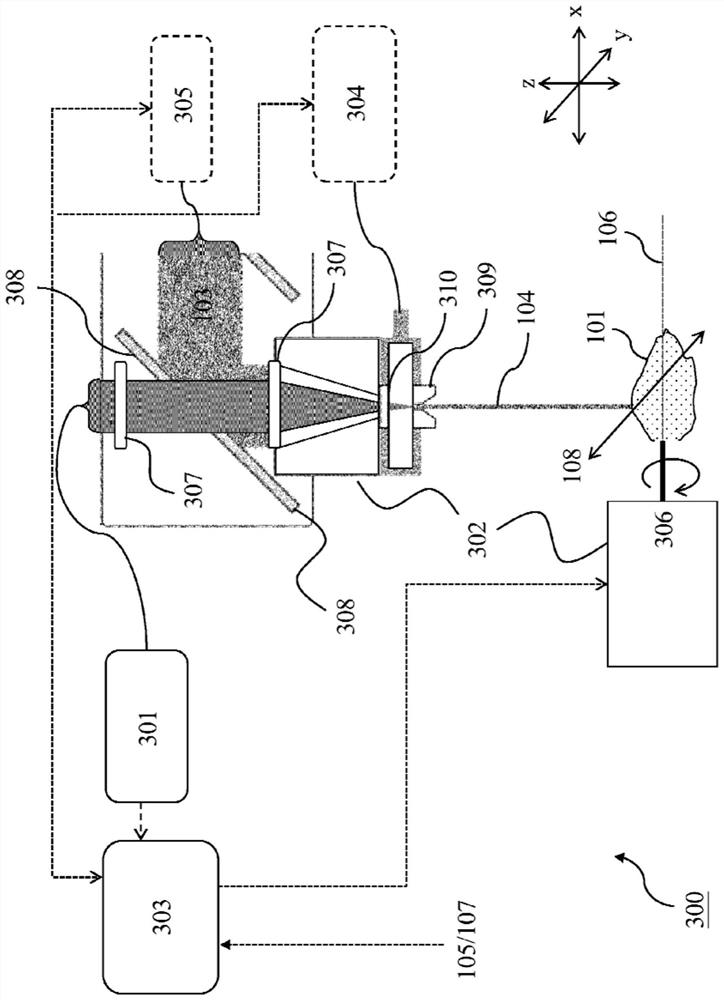

[0088] figure 1 A method 100 according to an embodiment of the invention is schematically shown. The steps of method 100 are at figure 2 is shown in the flowchart. The method 100 is suitable for manufacturing a workpiece 101 into a product 102 by successively cutting blocks of material from the workpiece 101 . The workpiece 101 may in particular be a rough diamond (see e.g. Figure 8 ), and product 102 may in particular be a faceted diamond (see e.g. Figure 7 ) or another faceted gemstone. Product 102 may be planned prior to performing method 100 , where the planning may be based on the shape and volume of workpiece 101 . To manufacture product 102 , method 100 continuously cuts away blocks of material from workpiece 101 until the desired complex shape of product 102 is achieved. To perform cutting, the method 100 utilizes an apparatus 300 that provides a laser beam 103 coupled into a pressurized fluid jet 104 (see image 3 ).

[0089] In particular, method 100 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com