Bevel cutting device of plasma cutting machine

A plasma cutting machine and groove cutting technology, which is applied in plasma welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of heavy weight, unsatisfactory assembly accuracy, and large structure, so as to improve quality and stability. performance, reduced size and weight, and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

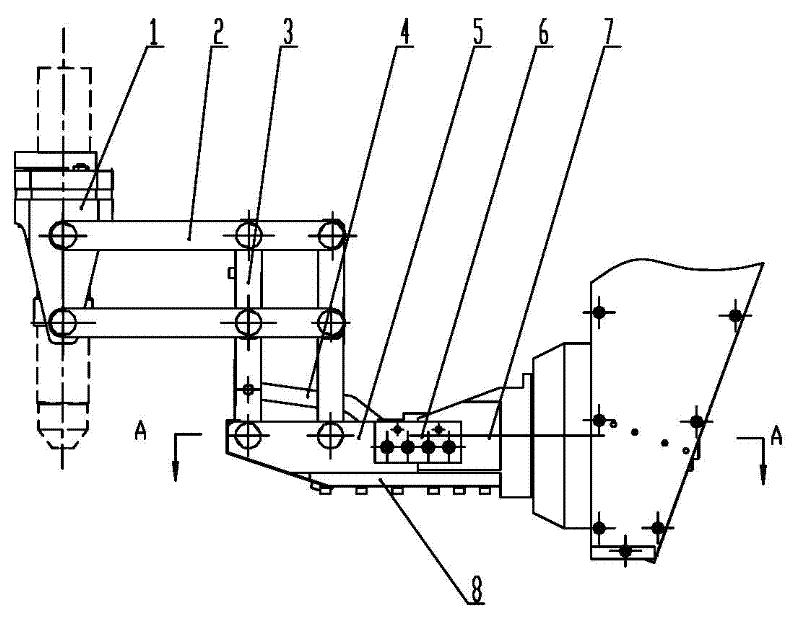

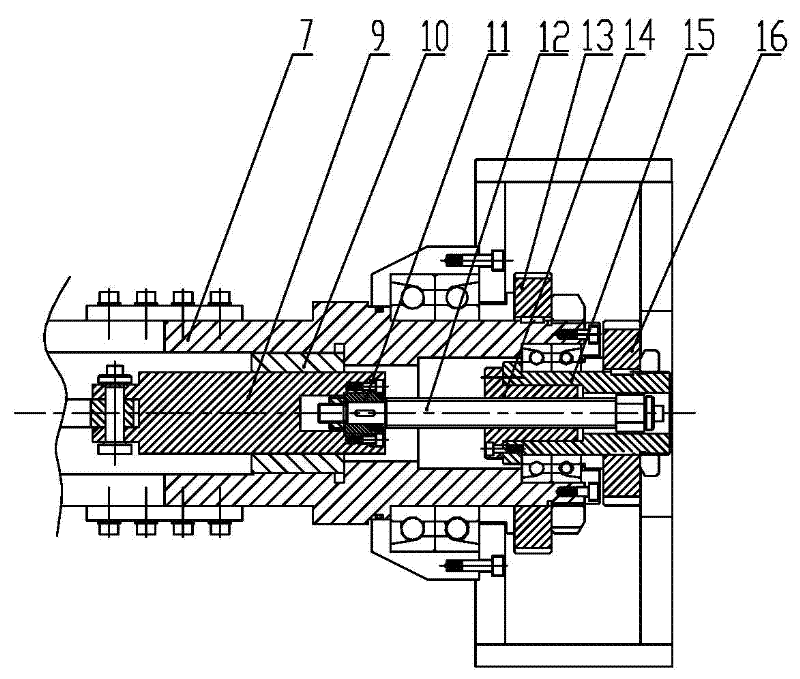

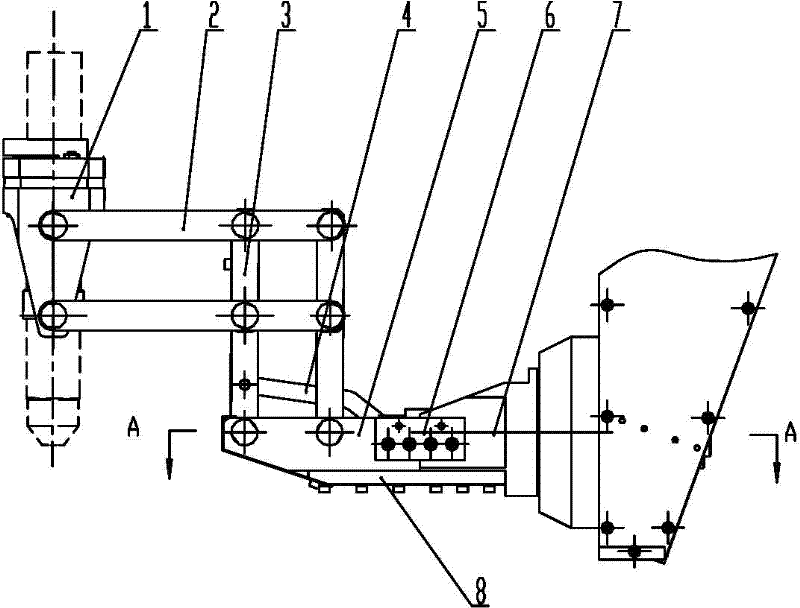

[0022] Such as figure 1 and figure 2 As shown, an embodiment of the ion cutting machine bevel cutting device of the present invention includes a gun body clamping linkage mechanism, a horizontal rotation mechanism and a longitudinal rotation mechanism, and the curved rod 4 of the gun body clamping linkage mechanism is connected to the longitudinal rotation mechanism The reciprocating shaft 9 of the mechanism is hinged, and the gun body clamping link mechanism is fixed with the rotary shaft 7 of the horizontal rotary mechanism through the fixed base plate 8 and the fixed seat 6, and the rotary shaft 7 is respectively connected with the fixed sleeve 10, Nut seat 15 is connected. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com