A kind of solid precursor source sublimation device and method for semiconductor processing

A sublimation device and semiconductor technology, applied in the direction of sublimation, separation methods, chemical instruments and methods, etc., can solve the problems of increasing the frequency of equipment shutdown, affecting the utilization rate of precursor sources, and unfavorable vapor deposition, so as to provide service life and reduce The effect of changing the frequency of bottle change and stabilizing the volatilization area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

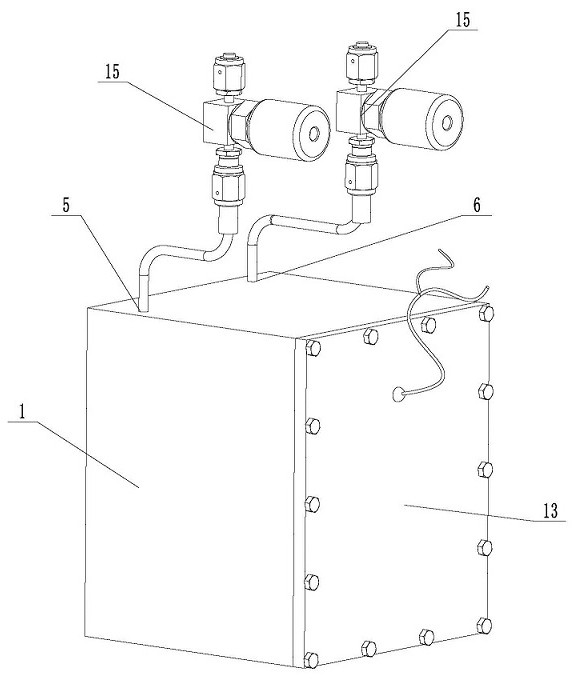

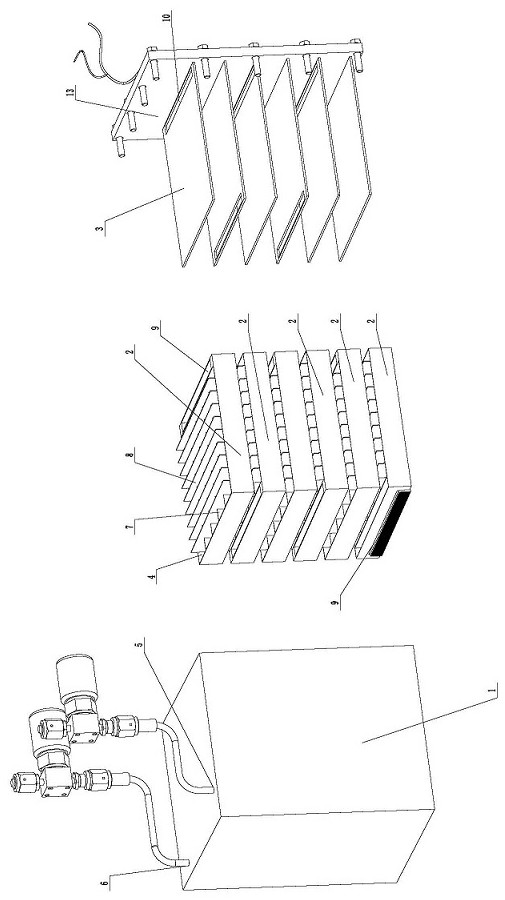

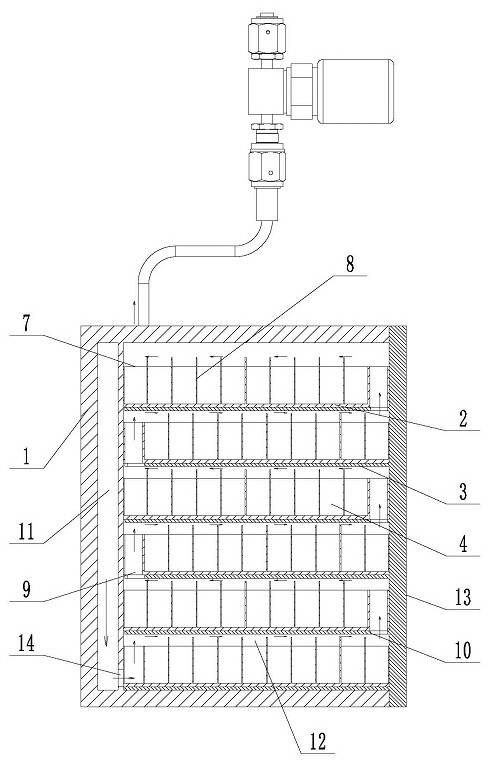

[0027] Embodiment 1: A kind of solid precursor source sublimation device for semiconductor processing (see attached figure 1 to attach image 3 ), including a storage box 1, a tray 2 installed in the storage box, an electric heating temperature control plate 3 installed at the bottom of the tray, a number of storage tanks 4 for loading solid-state precursor sources are densely covered on the tray, and several storage tanks are arranged in the storage box The upper and lower trays are arranged at intervals, the gap between the upper and lower adjacent trays forms a ventilation cavity, the uppermost tray and the top of the storage box form a ventilation cavity, and a ventilation groove 9 is provided on one side of the tray; the ventilation on the upper and lower adjacent trays One of the slots is on the left side of the tray, and the other is on the right side of the other tray. The ventilation slots connect all the ventilation chambers together to form a serpentine ventilation ...

Embodiment 2

[0040] Embodiment 2: A kind of solid precursor source sublimation device for semiconductor processing (see attached Figure 4 , attached Figure 5 ), its structure is similar to that of Embodiment 1, the main difference is that in this embodiment, an adjustment plate 16 is arranged on the upper part of the longitudinal baffle plate, the adjustment plate can be rotated, and a push-pull rod 17 is installed in the storage box, and the adjustment plates are all connected with the push-pull rod. The movement of the push-pull rod drives the adjustment plate to rotate, and a plurality of driving rods 18 are installed on one side of the adjustment plate and the material storage tank one by one. The lower end of the driving rod is placed in the material storage tank, and the piston cylinder 19 is installed outside the storage box. Magnetic block 20 is installed, and the slide block 21 that can attract each other with magnetic block is installed in the storage box, and slide block can s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com