Probe station for chip testing

A technology of chip testing and probe station, which is applied in electronic circuit testing, components of electrical measuring instruments, measuring electricity, etc., can solve problems such as inconsistency, unstable test data, fatigue of probe station, etc., and achieve fatigue elimination problems, eliminate small rotational offsets, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

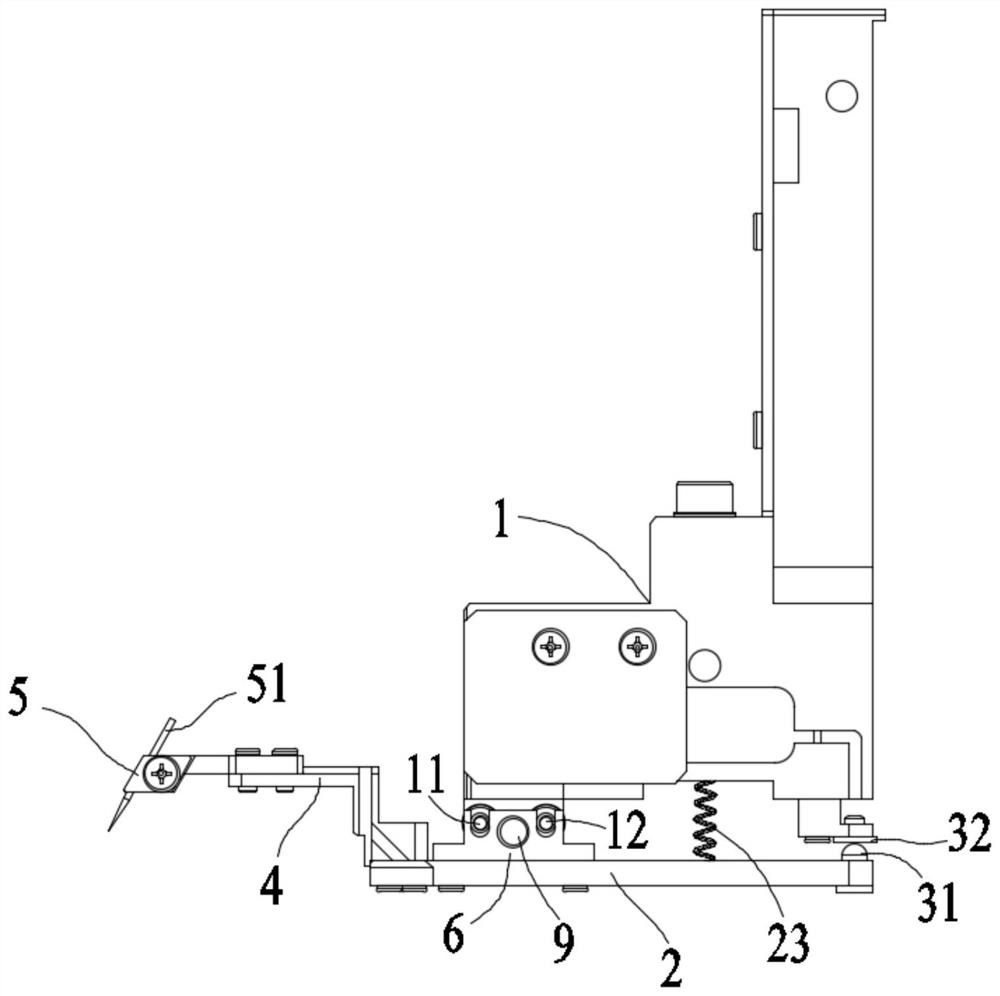

[0030] Example 1: A probe station for chip test, including the body 1, a support plate 2 located below the body 1, a probe 51 and a moving point contact probe 31, which is in contact with the chip to be tested, the probe 51. The moving point contact probe 31 is attached to both ends of the support plate 2, and the middle portion of the support plate 2 is connected to the body 1, and the lower end surface side of the body 1 is provided with one side. The static contact probe 32 corresponding to the moving point contact probe 31 and corresponds to the moving point contact probe 31;

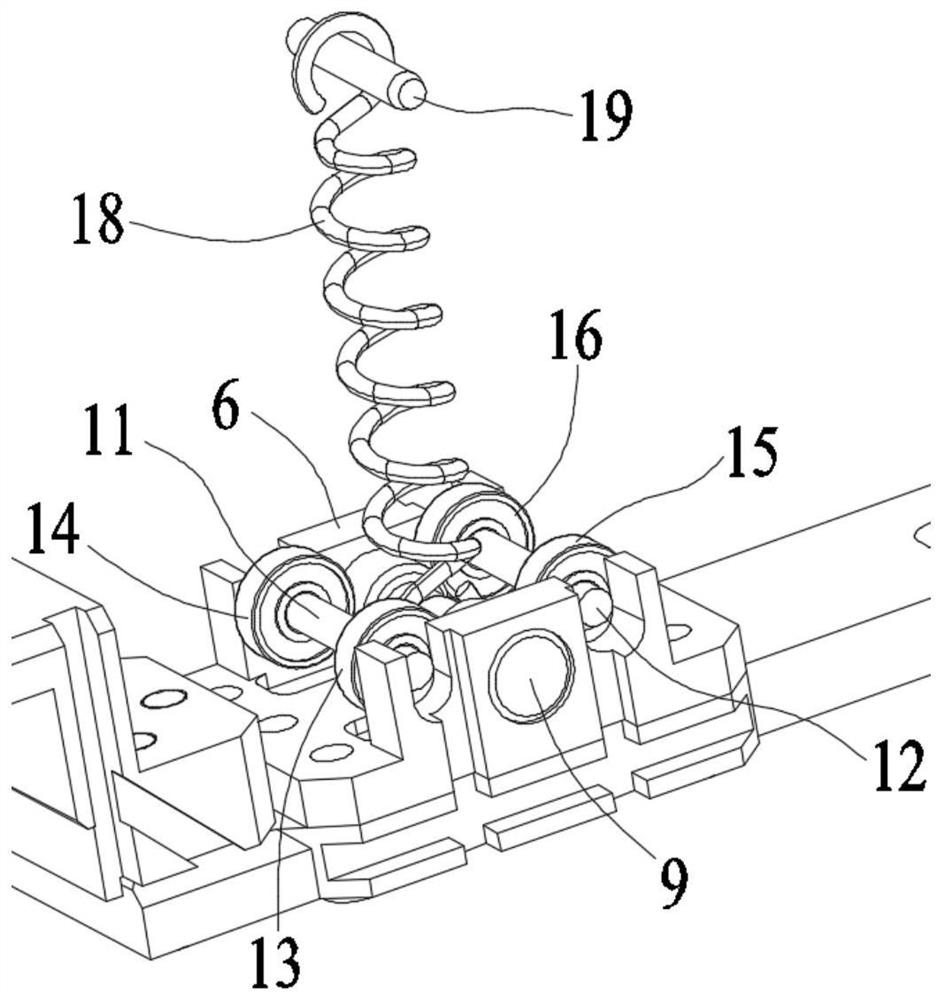

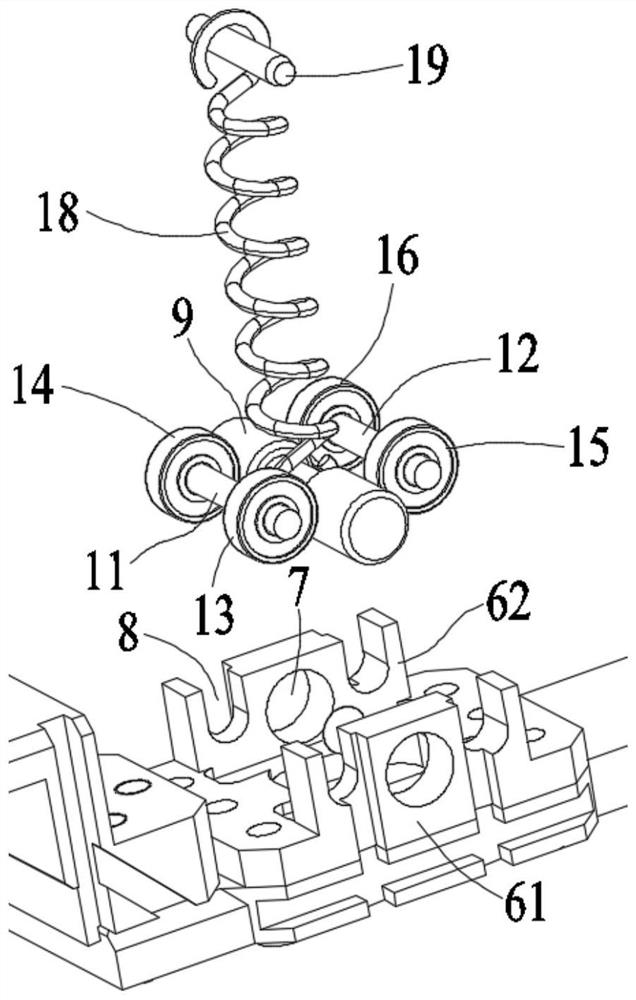

[0031]A first pin shaft 9 perpendicular to the length direction of the support plate 2 is mounted above the support plate 2 to the support plate 2, located between the probe 51 and the second elastic member 23, located at the lower end of the body 1 A second pin shaft 11 and a third pin shaft 12 parallel to the first pin shaft 9 are provided on the lower bumps 10, and the second pin shaft 11, the third ...

Embodiment 2

[0034] Example 2: A probe station for the chip test, including the body 1, the support plate 2 below the body 1, is used to contact the probe 51 and the moving point contact probe 31 in contact with the chip to be tested, the probe 51. The moving point contact probe 31 is attached to both ends of the support plate 2, and the middle portion of the support plate 2 is connected to the body 1, and the lower end surface side of the body 1 is provided with one side. The moving point contact probe 32 is located above the moving point contact probe 31, and when the probe is in contact with the chip to be tested, the moving point contact probe rotates away from the static contact probe, moving, static point The contact probe becomes the initial state of the mutual contact, and the control system of the chip test receives the moving, the stationary contact of the probe is separated from each other, and performs power-on operation to electrically conduct the probe and the chip electrically, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com