Magnetic force measuring device

A technology of magnetic force measurement and magnetic conduction, applied in the direction of magnetic performance measurement, etc., can solve the problems that the measurement results cannot be obtained, the lifting speed cannot be kept completely consistent, and the spring balance cannot maintain the maximum value, etc., and achieve high practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

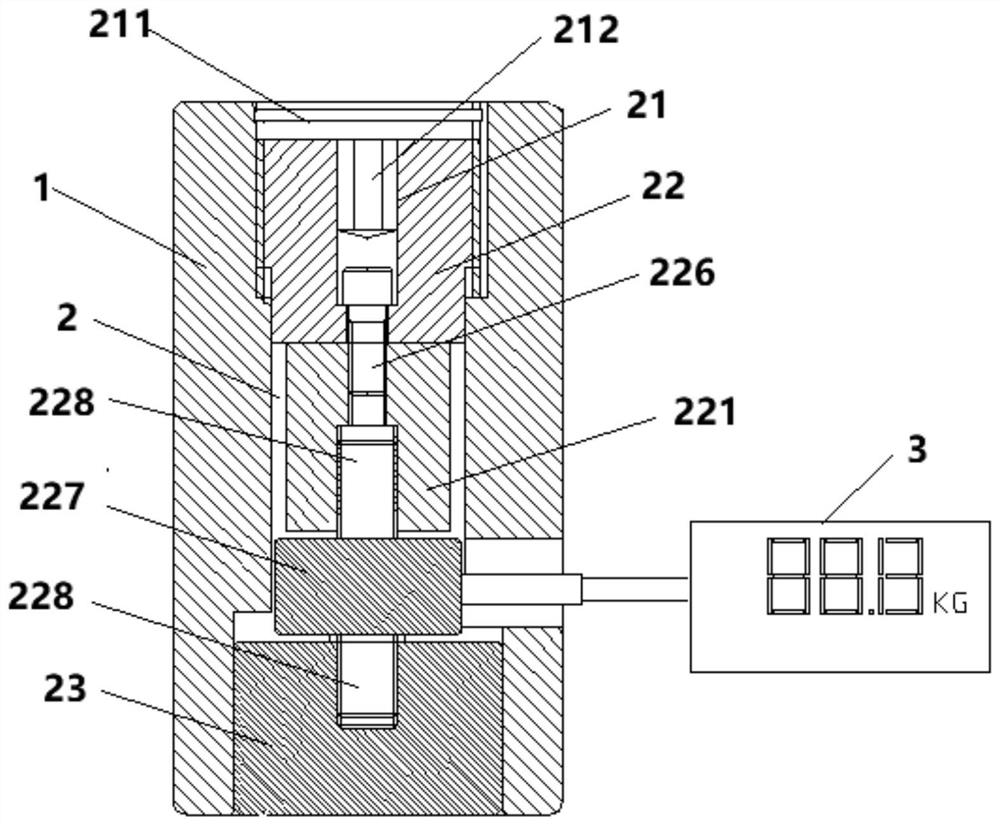

[0029] Such as figure 1 As shown, the first embodiment of the present invention discloses a magnetic measuring device, including a measuring body 1, the center of the measuring body 1 is provided with a longitudinal passage 2 along its axial direction, and the inside of the longitudinal passage 2 is arranged from top to bottom There is a lifting system 21, an intermediate system 22, a top block 23, and a pressure gauge 3 associated with the intermediate system 22. The bottom surface of the measuring body 1 is flush with the bottom surface of the top block 23 and forms the same contact plane that contacts the magnetic module. One of the measuring body 1 and the top block 23 is magnetically conductive, and the other is not magnetically conductive. When the lifting system 21 is subjected to an external force, it can drive the intermediate system 22 to move upward or downward in the longitudinal channel 2 to measure the The top block 23 exerts force to lift up or push the top bloc...

no. 2 approach

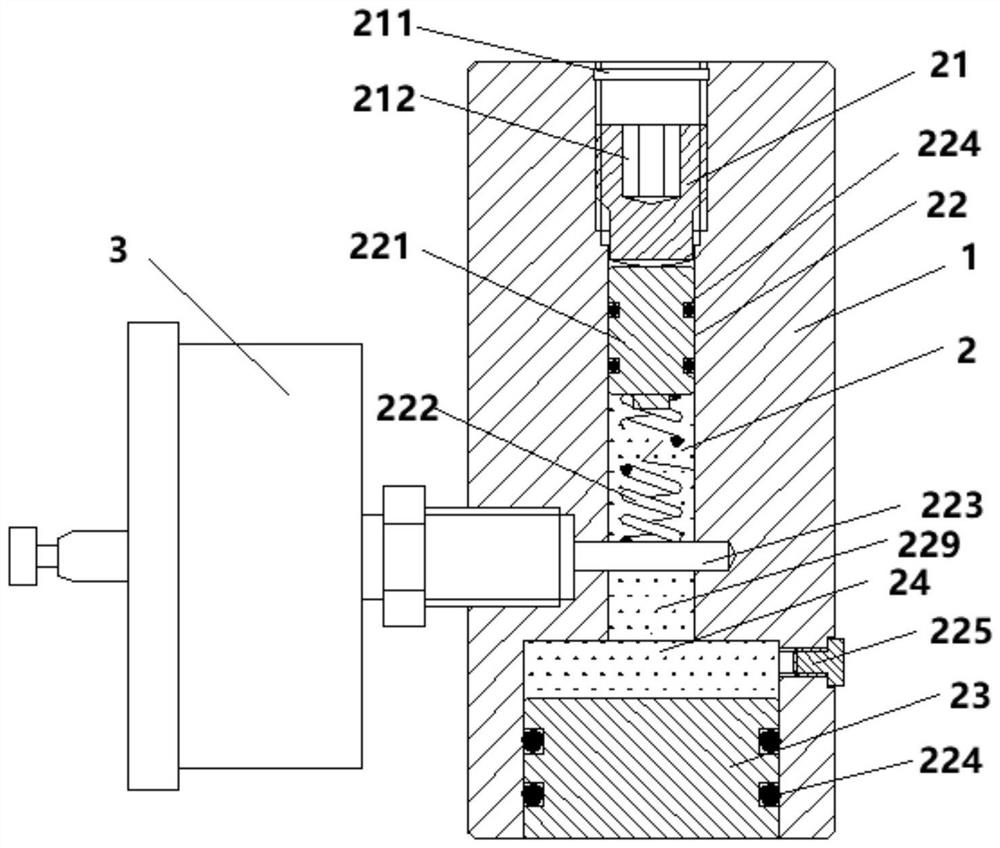

[0043] Such as figure 2 As shown, the second embodiment of the present invention discloses a magnetic measuring device, including a measuring body 1, the center of the measuring body 1 is provided with a longitudinal passage 2 along its axial direction, and the interior of the longitudinal passage 2 is arranged from top to bottom There is a lifting system 21, an intermediate system 22, a top block 23, and a pressure gauge 3 associated with the intermediate system 23. The bottom surface of the measuring body 1 is flush with the bottom surface of the top block 23 and forms the same contact plane that contacts the magnetic module. The measuring body 1 is magnetically conductive, and the top block 23 is not magnetically conductive. When the lifting system 21 is subjected to an external force, it can drive the intermediate system 22 to move upward or downward in the longitudinal channel 2, and the intermediate system 22 moves downward. When pushing the top block 23 to press the up...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap