Preparation device of face filling material

A technology for filling materials and preparation devices, which is applied to mixers, dissolvers, and mixers with rotating stirring devices, which can solve problems such as inability to ensure the uniformity of solvent injection and low efficiency of manual injection, and achieve flexible debugging and avoid The cumbersome manual operation and the effect of reducing cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

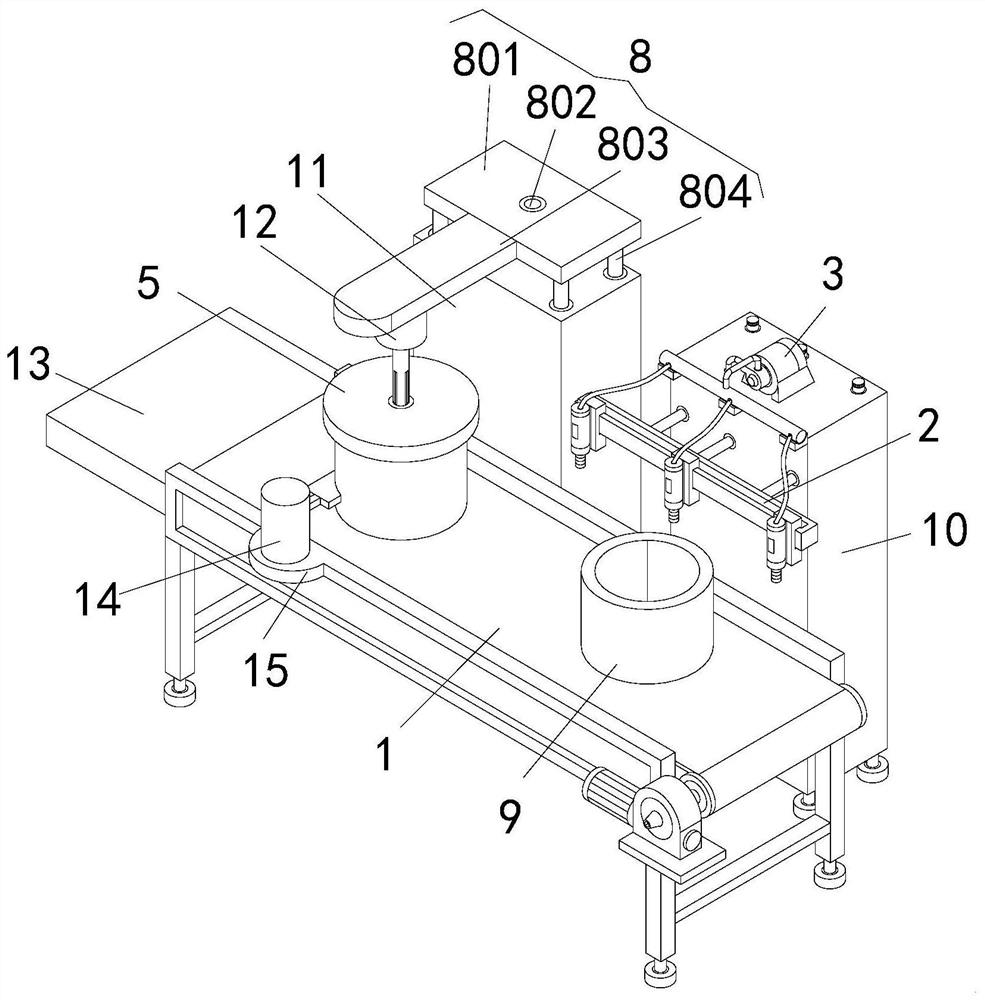

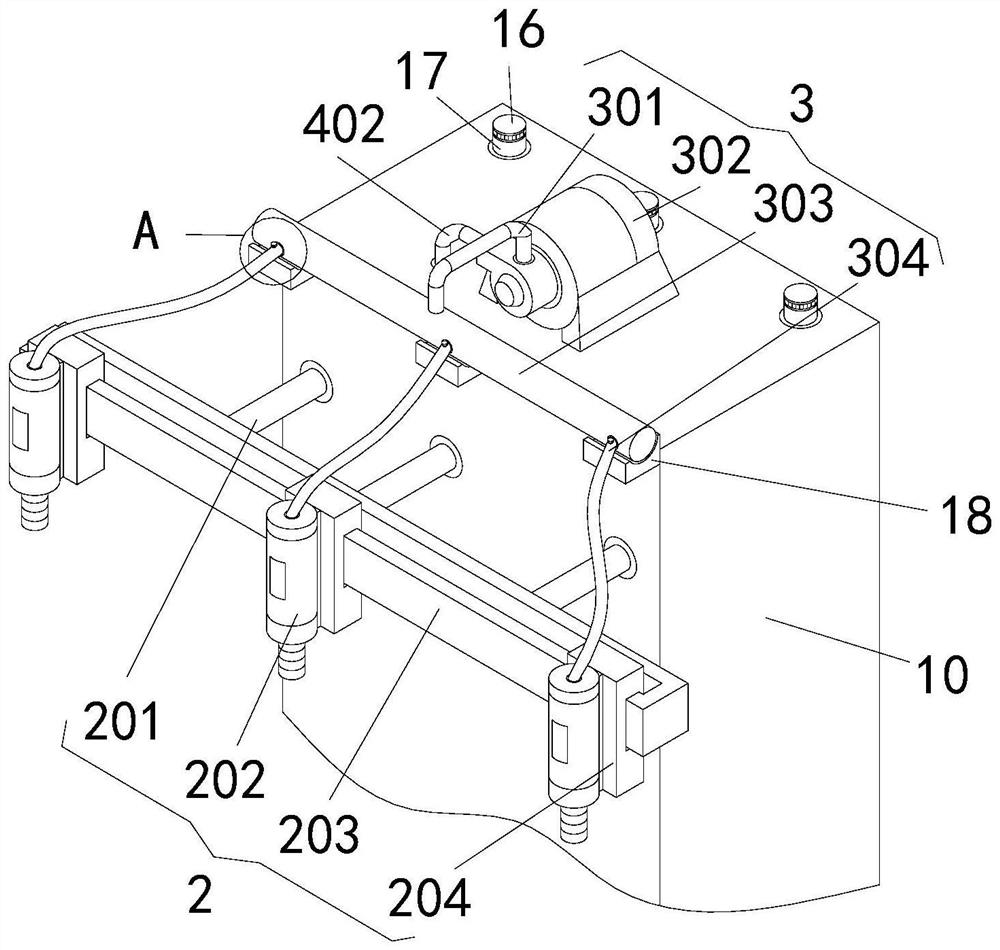

[0041] Such as Figure 1-10 As shown, a preparation device for facial filling materials includes a delivery platform 1, a liquid storage tank 10, and a support base 11. The liquid storage tank 10 and the support base 11 are located at the rear side of the delivery platform 1, and are respectively distributed on the delivery platform 1. both sides of

[0042] Mixing tank 9, the mixing tank 9 is located on the top of the conveyor table 1;

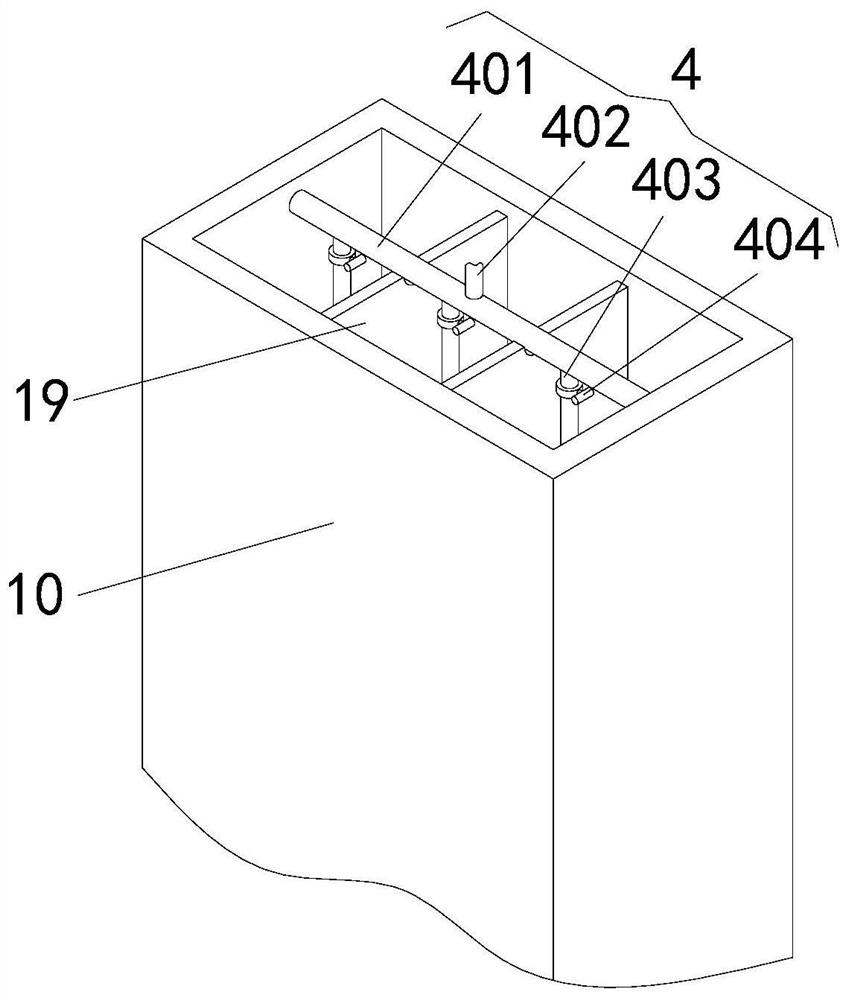

[0043] An injection mechanism 2, an infusion mechanism 3 and a liquid suction mechanism 4, the injection mechanism 2 is installed on the front side of the liquid storage tank 10, the infusion mechanism 3 is installed on the top of the liquid storage box 10, and the liquid suction mechanism 4 is install...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap