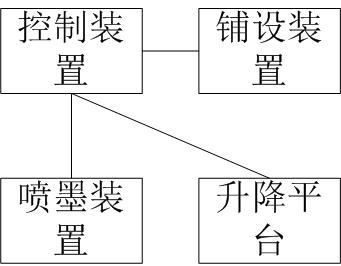

Removable-flask moulding 3D sand mold printing system

A boxless modeling and printing system technology, applied in the field of 3D printing, can solve problems such as low work efficiency, energy waste, and printing errors, and achieve the effects of improving work efficiency, saving energy, and avoiding printing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

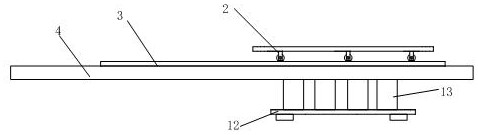

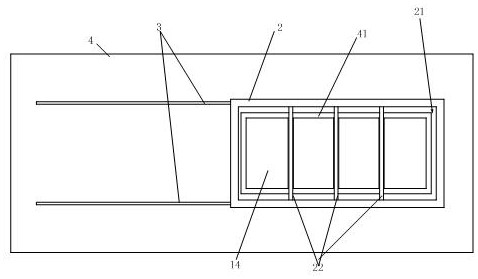

[0037] The present invention provides a boxless 3D sand mold printing system, refer to Figure 1-Figure 4 , as a specific embodiment, including a lifting platform 1 capable of vertical lifting and a bracket 2 arranged above the lifting platform 1, the lifting platform 1 includes a plurality of sub-platforms 1a, each of the sub-platforms 1a All can be lifted up and down independently, and the bracket 2 is provided with a plurality of channels 21 through which the plurality of sub-platforms 1a pass.

[0038] Specifically, by setting the lifting platform, and setting the lifting platform as multiple sub-platforms that can be lifted separately, and setting brackets on the lifting platform, in the actual printing process, the corresponding sub-platforms can be flexibly controlled according to the size of the sand mold. That is, the entire lifting platform does not need to be raised and lowered, thereby saving energy.

[0039] Further, as a preferred embodiment, refer to Figure 2...

Embodiment 2

[0047] Further, this application also provides a reference to the use method of a boxless 3D sand mold printing system Figure 5-Figure 7 , the method includes the following steps:

[0048] Step 1. Reference Figure 5 , placing a carrier plate 8 on the bracket 2;

[0049] Specifically, the carrier plate 8 is a flat plate, which is laid on the carrier plate 8 when laying the sand layer.

[0050] Step 2, controlling the lifting platform 1 to rise, and lifting the carrier plate to a preset height;

[0051] Step 3. Reference Figure 5-Figure 7 , the control device 7 controls the laying device 5 to lay a sand layer of a predetermined size on the carrier plate, (the sand layer of a predetermined size refers to a sand layer of a preset size set according to the size of the sand mold to be printed, and the laying The size of the sand layer can be guaranteed to form the coaming and sand mold mentioned below, so as to reduce the amount of sand grains); and the inkjet device 6 ejects...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com