Special-shaped magnesium ingot casting mold

A mold and magnesium ingot technology, applied in the field of magnesium casting, can solve problems such as difficulty in demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

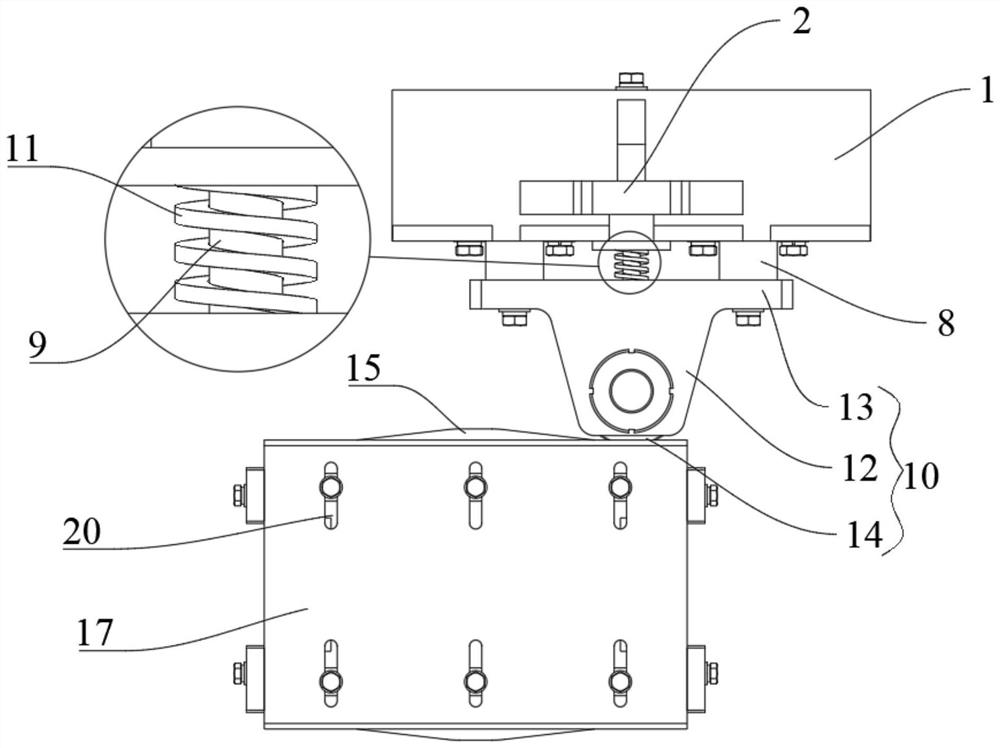

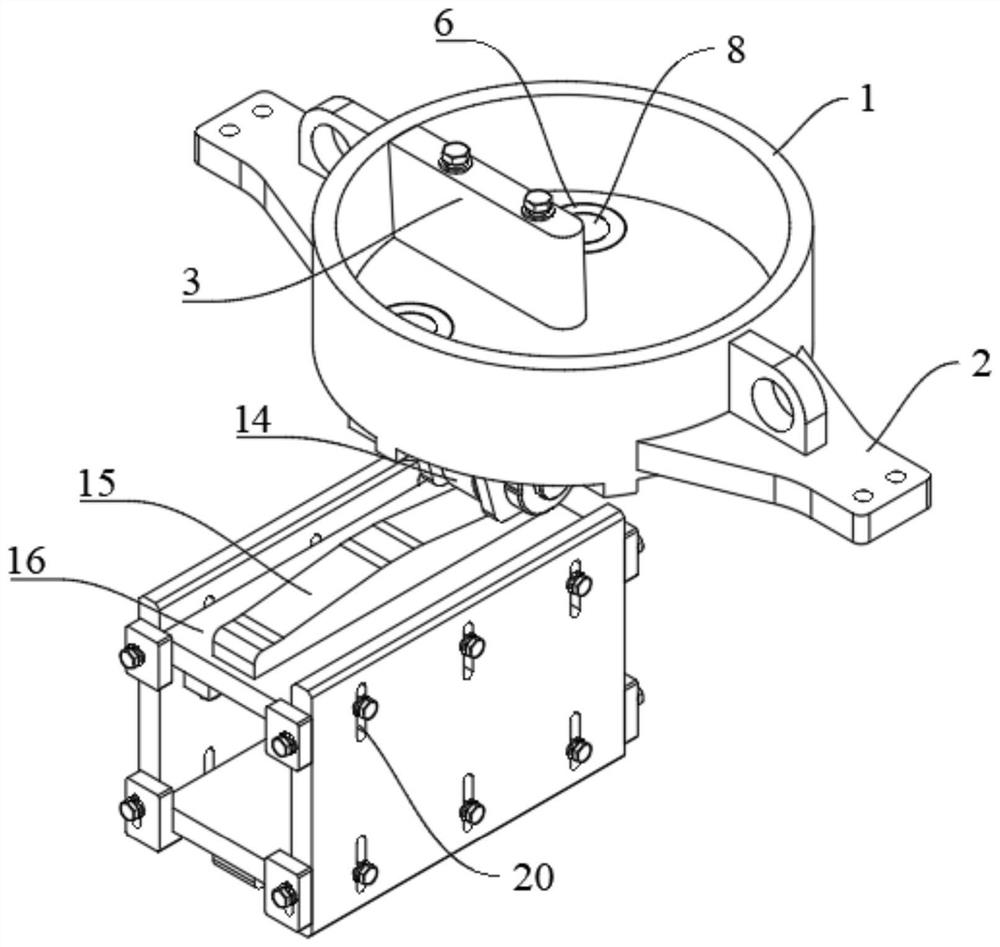

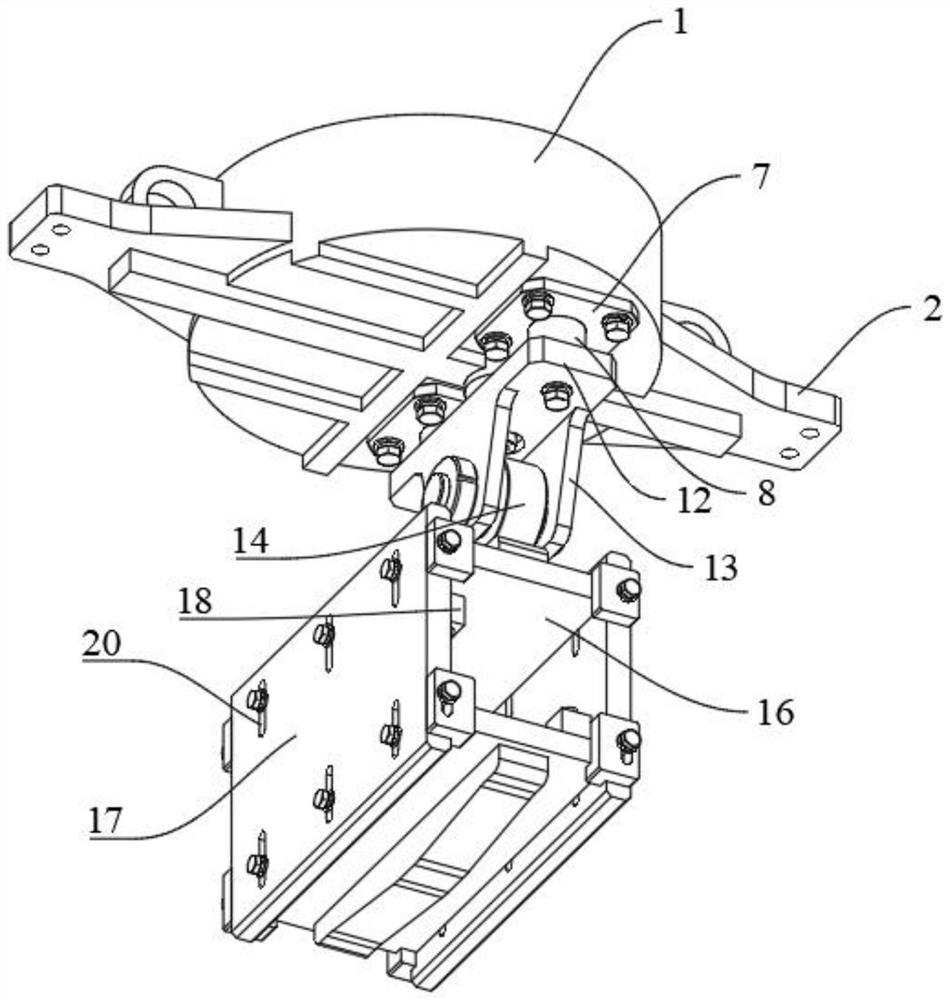

[0026] A special-shaped magnesium ingot casting mold, including a mold body, a pusher device, and a fixed base;

[0027] The mold body includes a circular tray 1, and also includes connecting wings 2 arranged on both sides of the circular tray 1, the connecting wings 2 are used to connect with the crawler of the pouring machine, and also includes a partition 3 arranged in the circular tray 1. The bottom of the circular tray 1 is also provided with two through holes 4, which are respectively arranged on both sides of the partition 3, and the through holes 4 are provided with inserts 5, and the inserts 5 are fixed to the bottom of the circular tray 1. Connection, the insert 5 includes a guide cylinder 6 and a connection seat 7, and a connection hole is opened on the connection seat 7; the guide cylinder 6 passes through the through hole 4 provided at the bottom of the circular tray 1, and the connection seat 7 and the circular tray 1 Connect the bottom surface of the bottom surf...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap