Externally-wrapped lower chord member and propeller strut web member fabricated truss

A herringbone and outsourcing technology, applied in the direction of construction and building structure, can solve the problems of complex mold system cost of storage space reinforcement, unable to reflect the prefabricated structure, occupying a large space, etc., to improve the cost The effect of large proportion, improved construction convenience, and accelerated construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

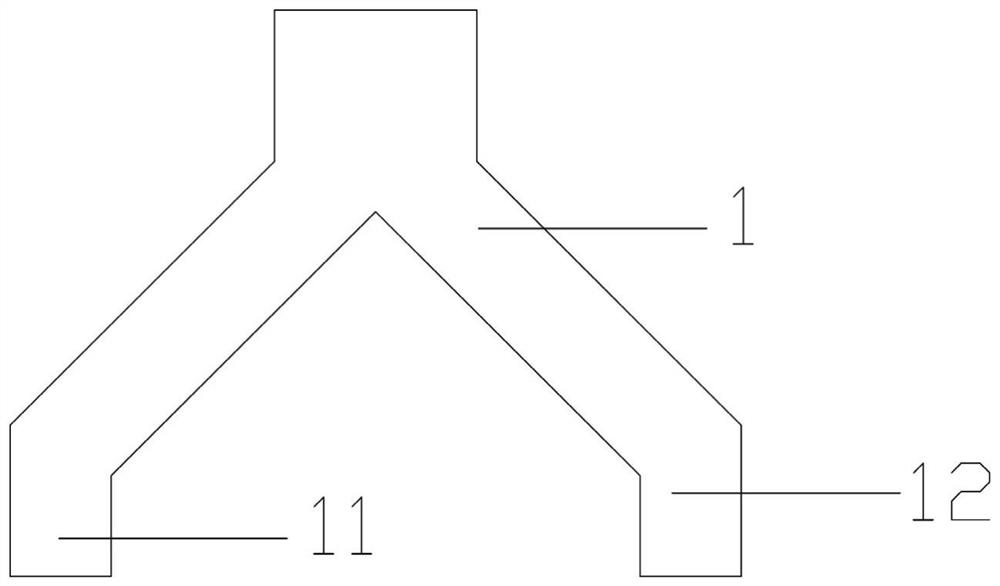

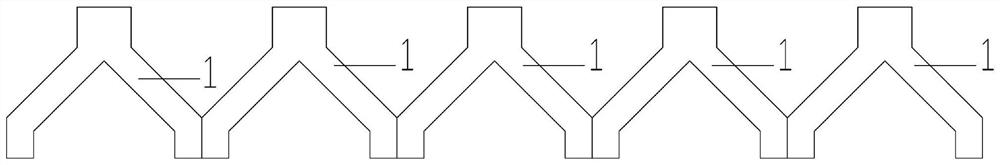

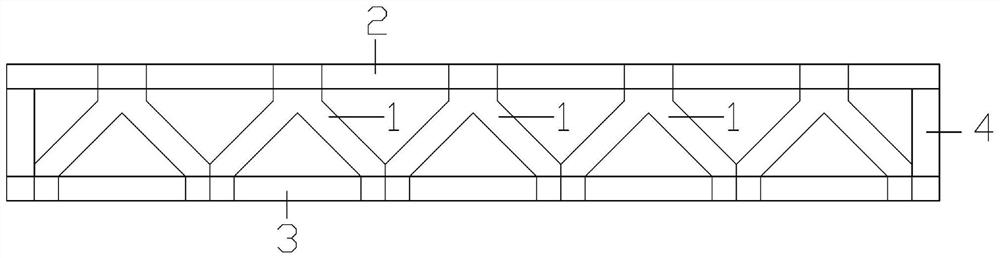

Embodiment 1

[0052] Step 1: Simultaneously prefabricate the gable frame, upper chord, outsourcing lower chord and end rod;

[0053] Step 2: Transport the above prefabricated components to the assembly site, fix the bottom chord at the set position, insert the first end of the lower part of the herringbone frame into the outsourcing bottom chord from above, between the herringbone frame and the outsourcing bottom chord Grouting in the gap between them forms the rear slurry, thereby fixing the herringbone frame and the lower chord, and assembling the prefabricated herringbone frame web;

[0054] Step 3: Spread the upper chord on the gable, and put the second end of the upper part of the gable into the hole of the upper chord;

[0055] Step 4: Insert tendons into the lower chord body, and stretch the tendons to tension the lower chord;

[0056] Step 5: Hoist the assembled and integrated outsourced bottom chord herringbone web-assembled truss to the required position.

[0057] The outsourced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com