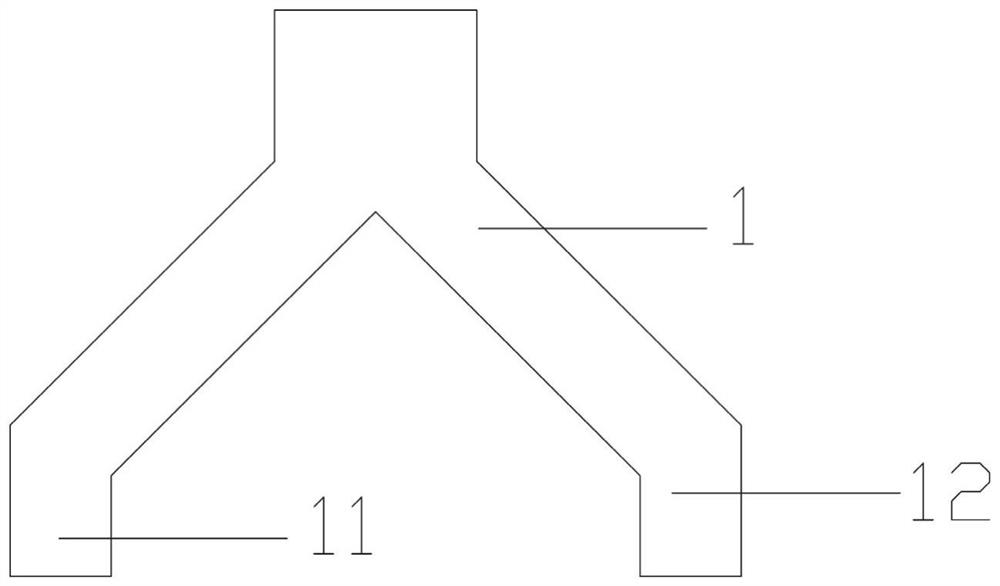

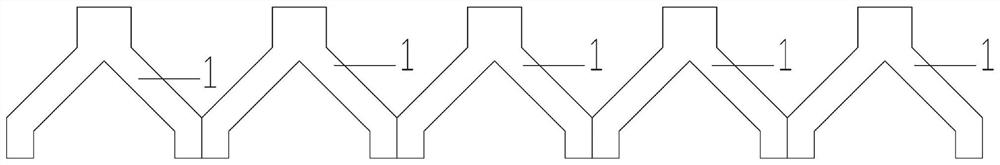

Fabricated double-T plate of propeller strut rib plate

A herringbone frame and assembled technology, which is applied in the direction of buildings, building components, and building structures, can solve the problems of storage and transportation space reinforcement constraints, increase, and project cost increase, which is conducive to application and promotion, and reduces The effect of reducing self-weight and storage and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

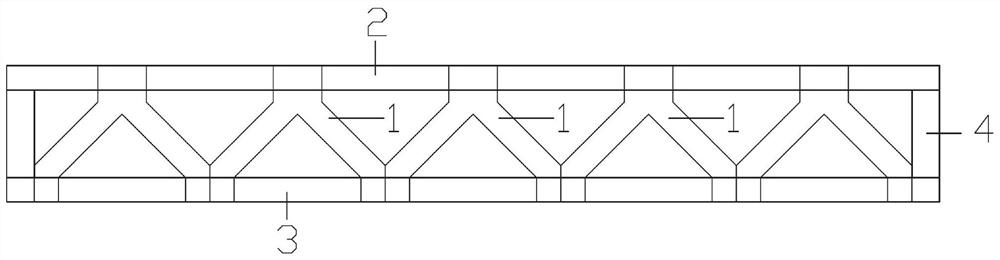

[0044] Step 1: Simultaneously prefabricate gables, wing panels, bottom chords and end bars;

[0045] Step 2: Transport the above-mentioned prefabricated components to the assembly site. First, assemble the gable frame and the lower chord, and connect the two gable frame ribs with horizontal connecting auxiliary components;

[0046] Step 3: Spread the wing plate on the gable frame, and put the upper end of the gable frame into the hole of the wing plate;

[0047] Step 4: Insert tendons into the lower chord body, and stretch the tendons to tension the lower chord;

[0048]Step 5: Hoist the assembled and integrated double T-plate with herringbone rib plate to the required position.

[0049] The assembled double T-plate structure proposed by the present invention is prefabricated in pieces and assembled on site, which is convenient for transportation and storage in the yard, saves costs, improves convenience, thereby greatly reducing the construction period, thereby bringing econ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com