Pantograph catenary arcing measurement sensor calibration device and calibration method

A technology for measuring sensors and calibrating devices, which can be applied to measuring devices, measuring electrical variables, instruments, etc., and can solve problems such as unconsidered effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

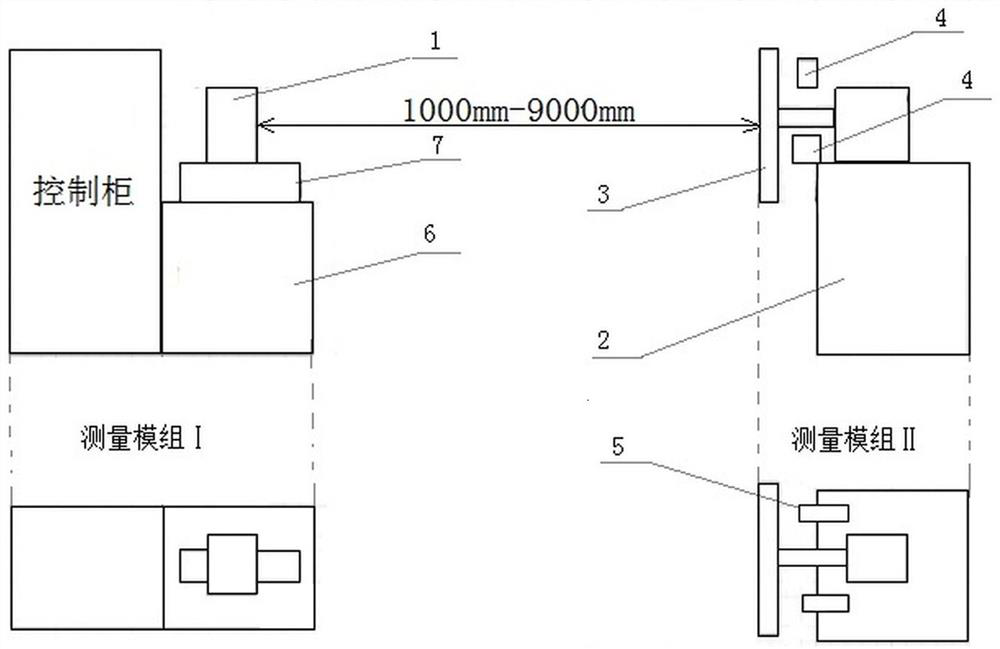

[0052] As one of the most basic implementations of the present invention, this embodiment discloses a pantograph-catenary arcing measurement sensor calibration device, such as figure 1 and 2 , including a relatively set measurement module and an arcing module, the measurement module includes an adjustment platform 6, and the adjustment platform 6 is provided with a front and rear translation platform 7, and the arc sensor 1 to be calibrated is arranged on the front and rear translation platform 7 Above, the adjustment platform 6 realizes the movement in the up and down and left and right directions under the control command, and the front and rear translation platform 7 drives the arc sensor 1 to be calibrated to realize the movement in the front and rear direction under the control command. When the up and down direction, left and right direction and Combined adjustments in the front and rear directions can ensure that different types of arcing sensors 1 to be calibrated can ...

Embodiment 2

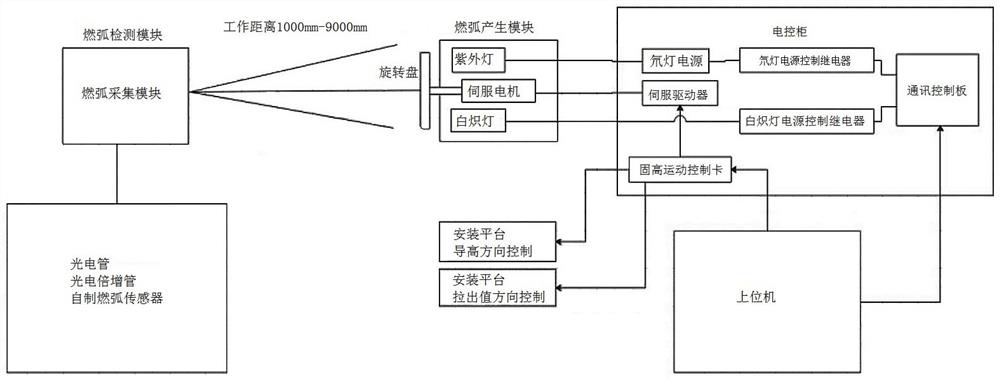

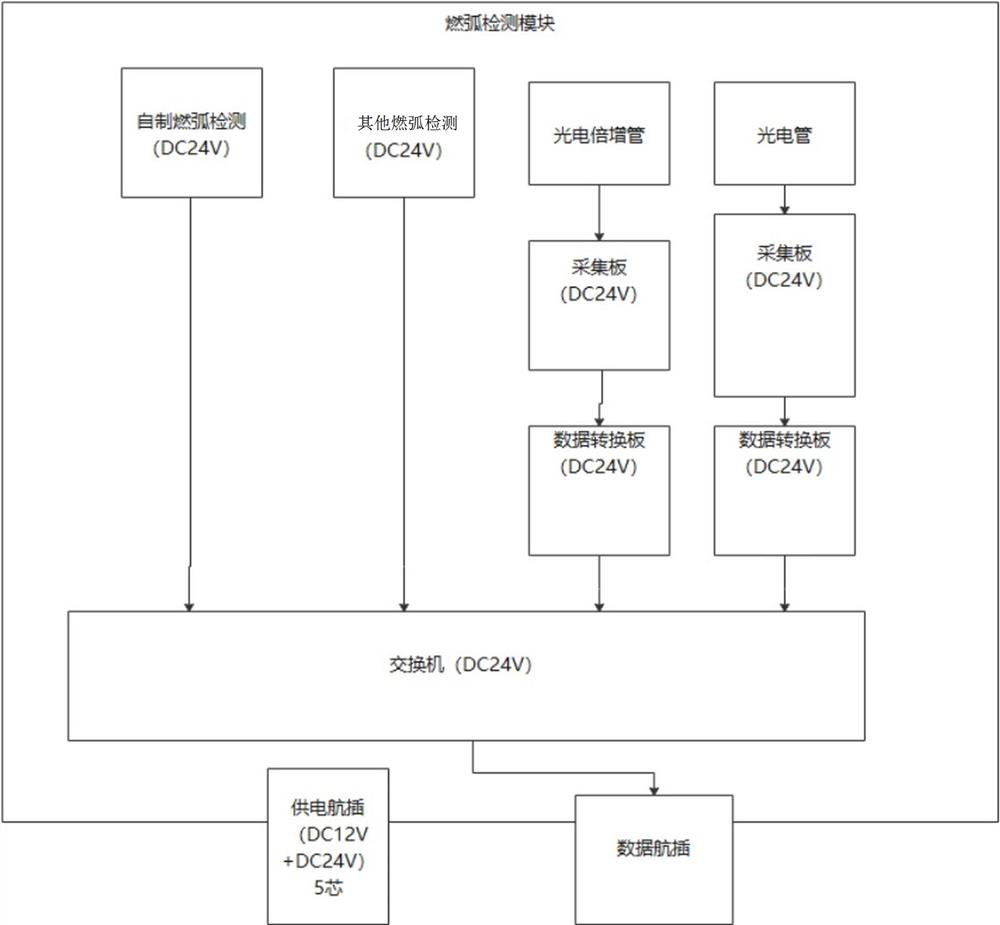

[0056] As a preferred embodiment of the present invention, on the basis of the technical solution of the above-mentioned embodiment 1, further, such as image 3 The arc sensor 1 to be calibrated is set on the forward and backward translation platform 7 through the arc acquisition module. The arc acquisition module is compatible with different types of sensors, which can facilitate the calibration of different types of arc sensors 1 .

[0057] Preferably, the installation platform 2 moves up and down (height guide direction) and left and right (pull-out value) directions under control instructions. relative movement. Optionally, the arc sensor 1 to be calibrated, the rotating disk 3 for simulating arc generation, the light source, etc. can also be installed and fixed on the measurement module and the arc module respectively.

[0058] More specifically, the vertical movement height range of the installation platform 2 and the adjustment platform 6 is + / -200mm, and the left and ...

Embodiment 3

[0069] Corresponding to the arcing calibration devices of the above-mentioned embodiments 1 and 2, this embodiment provides a calibrating method for the pantograph-catenary arcing measurement sensor, including the steps of installation and adjustment of the arcing sensor 1, data collection and parameter calibration.

[0070] Specifically, the arc sensor installation and adjustment step is to fix the arc sensor 1 to be calibrated on the front and rear translation platform 7 on the adjustment platform 6 in the measurement module, and adjust the adjustment platform 6 and the arc module. The distance between the platforms 2 and the front and rear positions of the front and rear translation platforms 7 adjust the distance between the arc sensor 1 to be calibrated and the rotating disk 3 on the arc module to a predetermined range, and by adjusting the Adjust the height and left and right positions of the platform 6 and / or the installation platform 2, and adjust the guide height in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com