Coal face advancing speed optimization method based on coal rock stress loading experiment

A coal mining face, stress loading technology, applied in the direction of applying stable tension/pressure to test material strength, material inspection products, measuring devices, etc., can solve the problem of inability to accurately restore the deformation and failure characteristics of coal and rock mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

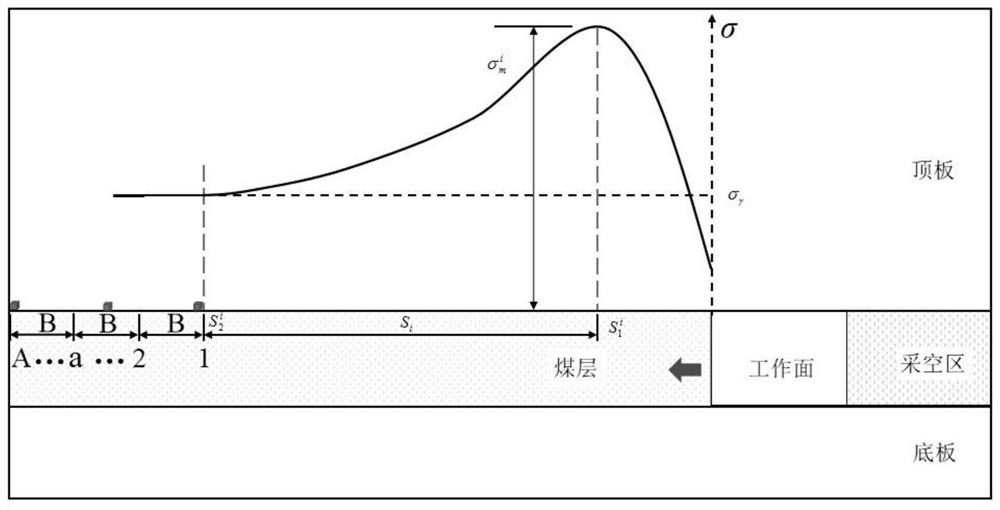

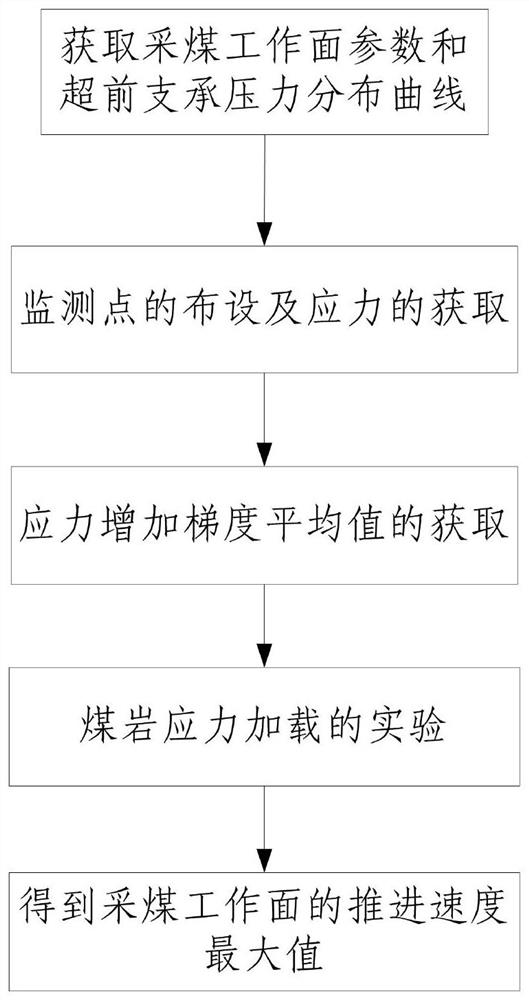

[0057] like Figure 1 to Figure 3 A method for optimizing the advancing speed of coal mining face based on the stress loading experiment of coal and rock is shown, and the method includes the following steps:

[0058] Step 1. Obtain the parameters of the coal mining face and the distribution curve of the advance bearing pressure:

[0059] Step 101, obtaining the cutting depth B of the shearer and the burial depth H of the coal mining face;

[0060] Step 102, according to formula v i =n i ×B, get the ith propulsion speed v i ; where n i Indicates the i-th daily set value of the number of coal cutting knives, i is a positive integer;

[0061] Step 103: According to the mine pressure monitoring system, take the distance from the coal mining face as the abscissa and the pressure as the ordinate to obtain the i-th propulsion speed v i The leading bearing pressure distribution curve of the coal seam before the lower coal face is recorded as the i-th leading bearing pressure di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com