Compact double-layer secondary Tesla type pulse transformer

A pulse transformer, compact technology, applied in the direction of transformer/inductor shell, transformer/inductor magnetic core, transformer/inductor parts, etc., can solve the problem of affecting system stability, increasing transformer volume and weight, and not meeting miniaturization , compactness requirements and other issues, to achieve the effect of reducing the probability of insulation breakdown, reducing the overall length and realizing miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

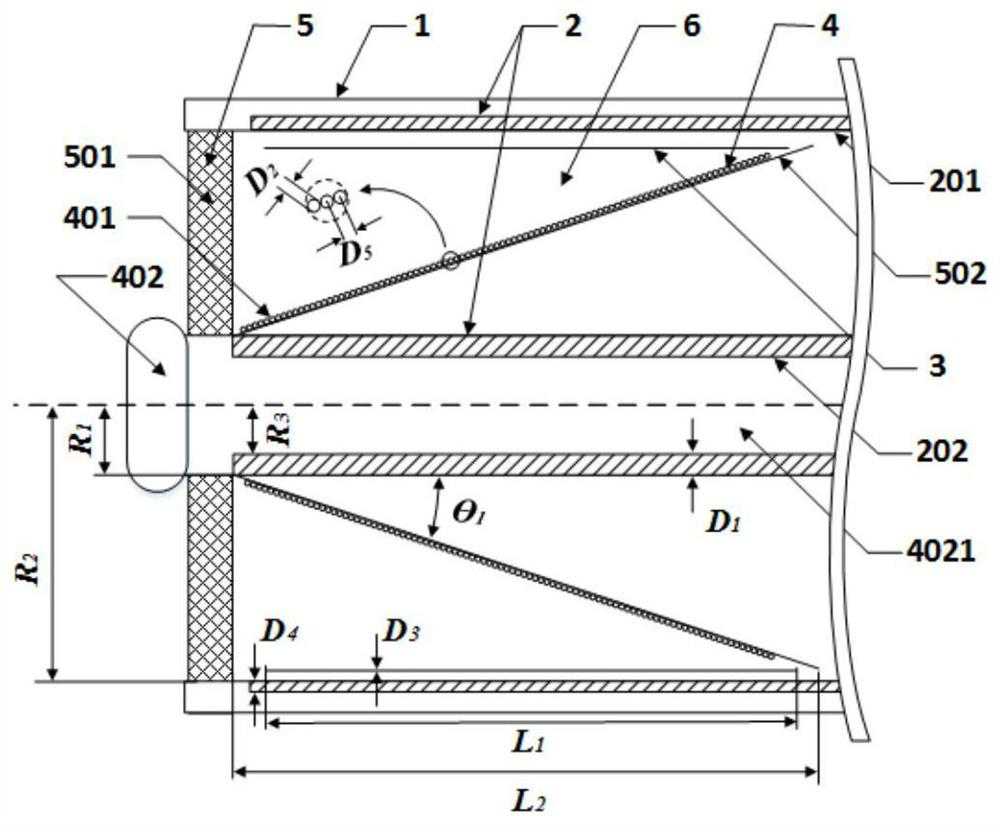

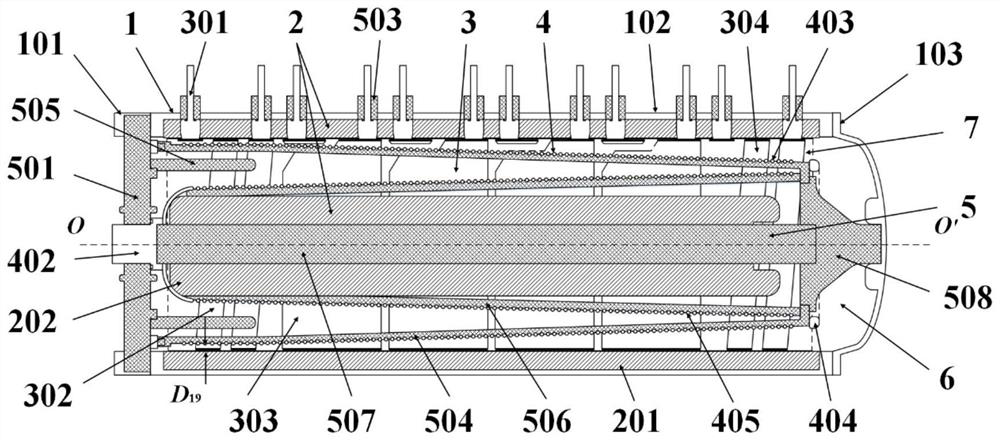

[0075] The input voltage V of the designed Tesla transformer p The peak value is 2kV, the step-up ratio N is greater than 300, and the output voltage V s The peak value is above 600kV, and the leading edge of the pulse is 46μs, which realizes stable operation with a long repetition frequency of 30Hz. The specific design dimensions of the embodiment are:

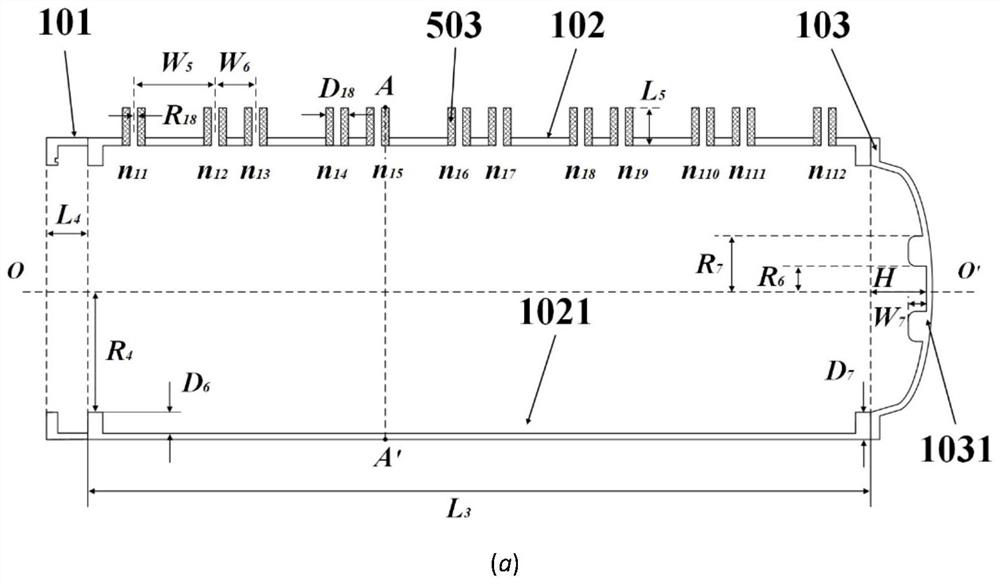

[0076] Shell 1 overall length L 3 1200mm, inner diameter R 4 164mm, thickness D 7 is 36mm. The length L of the edge pressing ring 101 4 60mm, inner diameter R 4 It is 164mm. End cover plate 103 inner diameter R 4 164mm, ring protrusion 1031 inner diameter R 6 30mm, outer diameter R 7 60mm, depth W 7 is 24mm.

[0077] Outer magnetic core 201 length L 6 1000mm, thickness D 6 is 28mm, the inner radius is equal to R 4 It is 164mm, and the width of the upper end gap is 203 W 8 30mm, the relative magnetic permeability of the outer magnetic core 201 μ s It is around 2000. Inner magnetic core 302 length L 8 950mm, o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Inner radius | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com