Image-sensing system and detection and correction method for defective photosensitive element

A technology of image sensing and image sensor, which is applied to TV system components, electrical components, image communication, etc., and can solve the problem of decreased power consumption of buffers and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] A variety of embodiments of the present invention will be described below. The basic concepts of the present invention are described below and is not intended to limit the contents of the invention. The scope of the actual invention should be defined in accordance with the scope of the application.

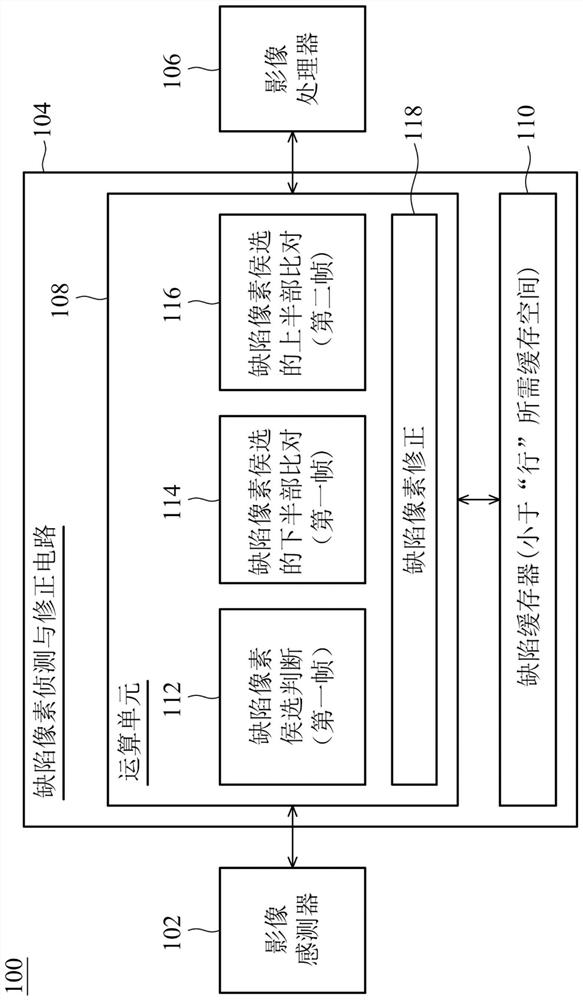

[0041] figure 1 An image sensing system 100 implemented in accordance with an embodiment of the present case, for example, a camera, or a camera. Image sensing system 100 includes an image sensor 102 (e.g., CMOS Image Sensor), a defective pixel detection and correction circuit 104, and an image processor 106. The defective pixel detection and correction circuit 104 are coupled between the image sensor 102, and between the image processor 106, including one operation unit 108, and a defect buffer 110. The arithmetic unit 110 can include a logical operation hardware, and a memory containing a hardware operation code. The arithmetic unit 110 detects a defective photosensitive ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com