Multi-element modified graphene quantum dot composite lubricating oil additive and preparation method thereof

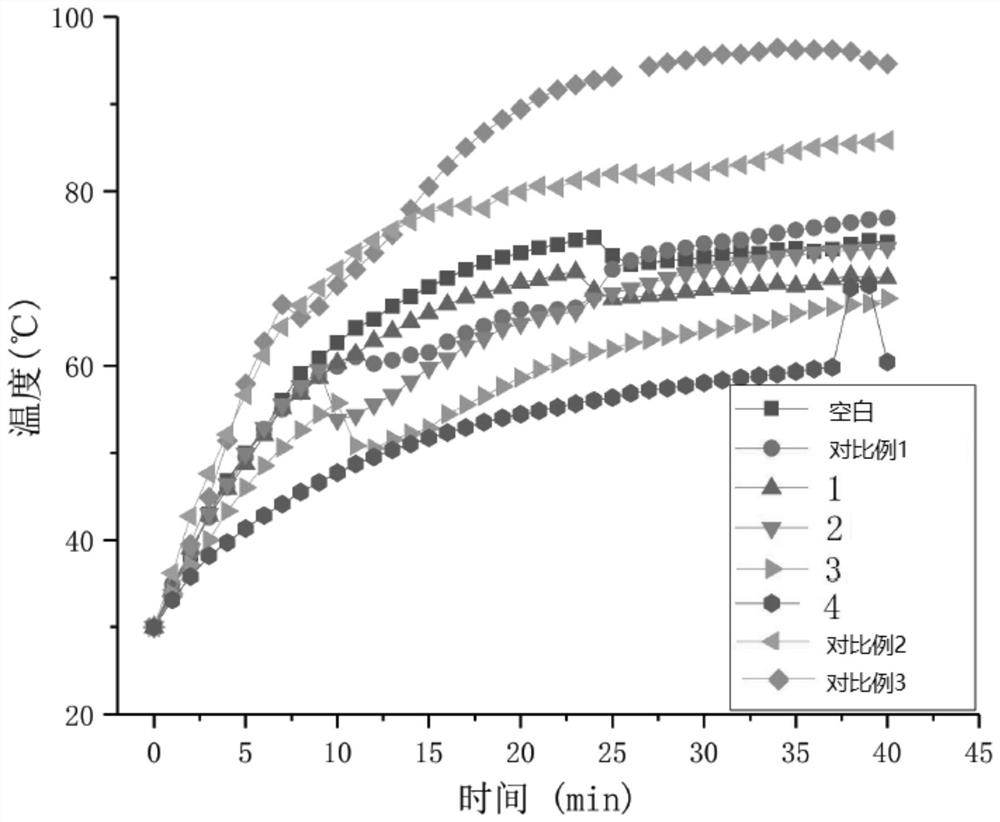

A graphene quantum dot and multi-element technology, applied in the direction of additives, petroleum industry, lubricating composition, etc., to achieve the effects of improving lubrication, shortening carbonization reaction time, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

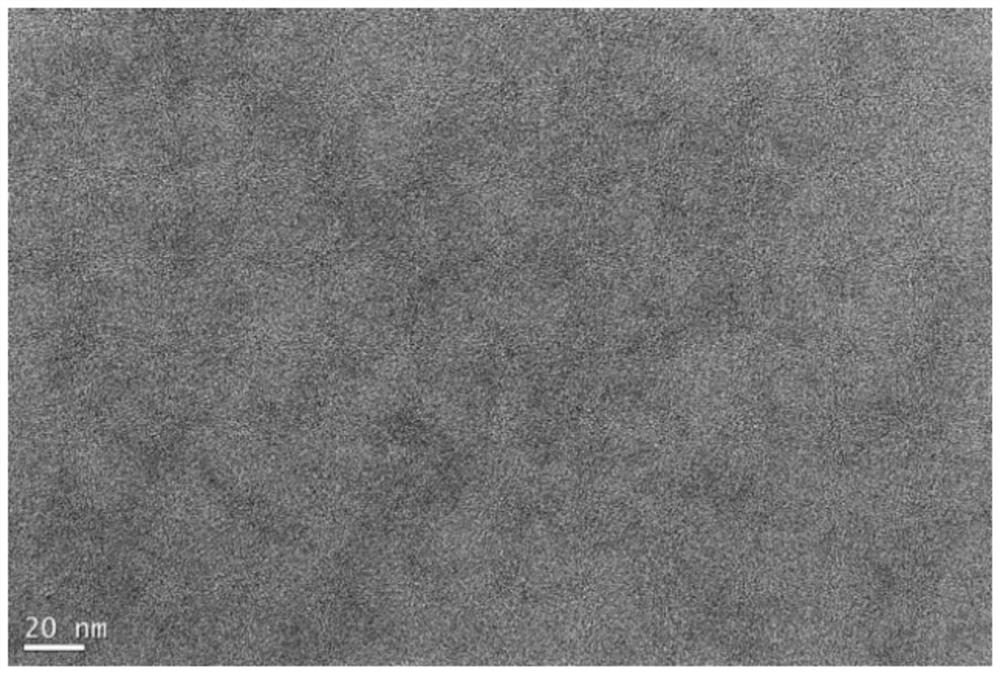

[0045] A hydrophobic multi-element modified graphene quantum dot, the preparation method of which includes the following steps:

[0046] Doping reaction: in the reaction kettle, non-aqueous solvent, carbon source, doped element precursor and catalyst were added sequentially, stirred evenly and then refluxed completely, to give mixture A;

[0047] Hydrophobic modification reaction: hydrophobic reagent is added to mixture A, the reflux reaction is sufficient, solid-liquid separation, filtrate is removed from the unless water solvent is obtained hydrophobic multi-element modified graphene quantum dots;

[0048] Wherein, the doped elements are at least 2 of B, N and Si, preferably, the amount of doped element precursors is 0.6 to 0.9 times that of the carbon source.

[0049] In some examples, the non-aqueous solvent is a monohydrate, a mixture of binary alcohols.

[0050] In some examples, the boiling point of the monohydrol at standard atmospheric pressure is not less than 75 ° C, furt...

Embodiment 1

[0078] 1) Doping reaction: in the reactor sequentially add 8 parts (mass ratio) ethanol and ethylene glycol (volume ratio 2:1) mixture, 1 part citric acid and its butyl ester (volume ratio 1:1) mixture, 0.1 part boric acid and ethyl borate (mass ratio 1:1), 0.6 parts tetraethyl silicate, 0.1 parts of six methyltetraamine and 0.2 parts of transition metal composite oxide LiMn 0.5 Ni 0.5 O 2 After stirring well, it should be refluxed at 180 °C for 2h and cooled to room temperature;

[0079] 2) Hydrophobic modification reaction: C18 fatty amine is added to the mixture, then refluxed for 2h, centrifuged after cooling, the filtrate is a hydrophobic fossilene quantum dot solution containing multi-element modified hydrophobic graphene, and hydrophobic poly-element doped graphene quantum dots are obtained after the solvent is removed by vacuum at 80-150 °C.

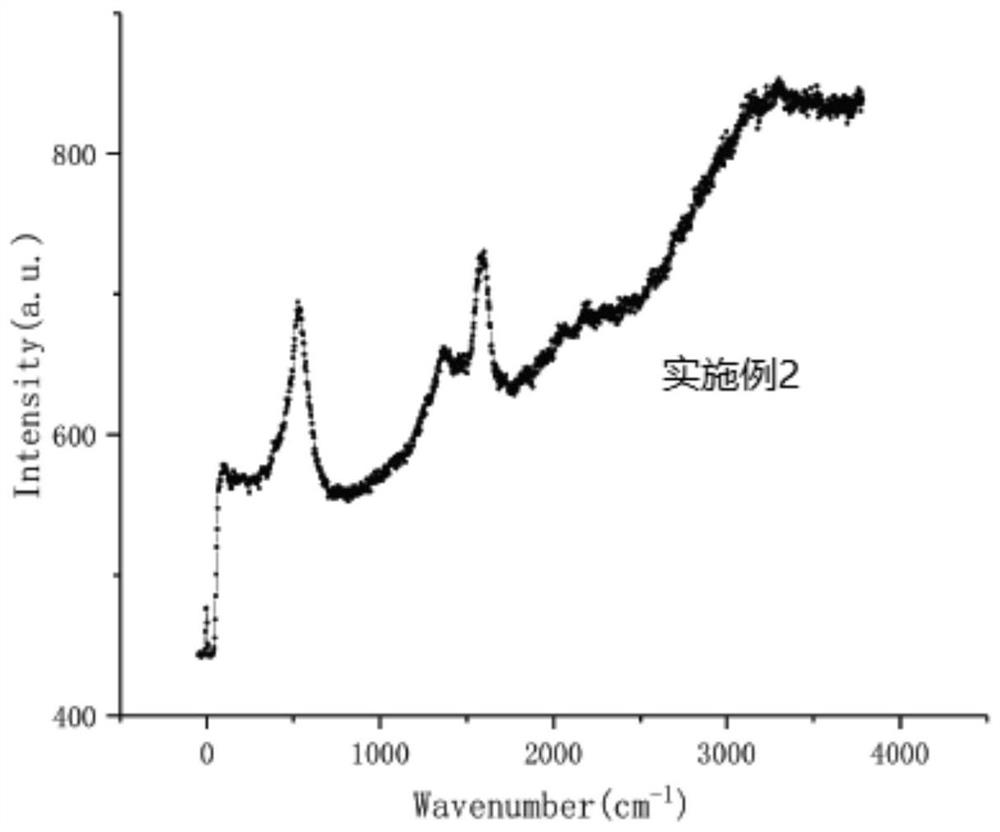

Embodiment 2

[0081] 1) Doping reaction: in the reactor sequentially added 8 parts (mass ratio) ethanol and ethylene glycol (volume ratio 1:1), 1 part butyl citrate and urea (mass ratio 1:1), 0.1 part boric acid and butyl borate ester (mass ratio 1:1), 0.6 parts tetraethyl silicate and phenyl siloxane (mass ratio 1:1), 0.1 parts of sixth methyltetraamine and 0.2 parts of LiNiO 2With ZnO (mass ratio 1:1), stir well and then reflux at 220 °C for 2h and cool to room temperature;

[0082] 2) Hydrophobic modification reaction: C10 fatty amine is added to the mixture, and then refluxed for 2h, centrifuged after cooling, the filtrate is a hydrophobic fossilene quantum dot solution containing multi-element modification, and the solid paste is obtained after the solvent is removed by vacuum at 80-160 °C, and the hydrophobic multi-element doped graphene quantum dots are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com