Bearing cooling structure of small turbojet engine

A technology of turbojet engine and cooling structure, which is used in engine cooling, engine lubrication, turbine/propulsion cooling, etc., can solve problems such as insufficient fuel combustion, increased engine cost and weight, and sufficient fuel preheating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

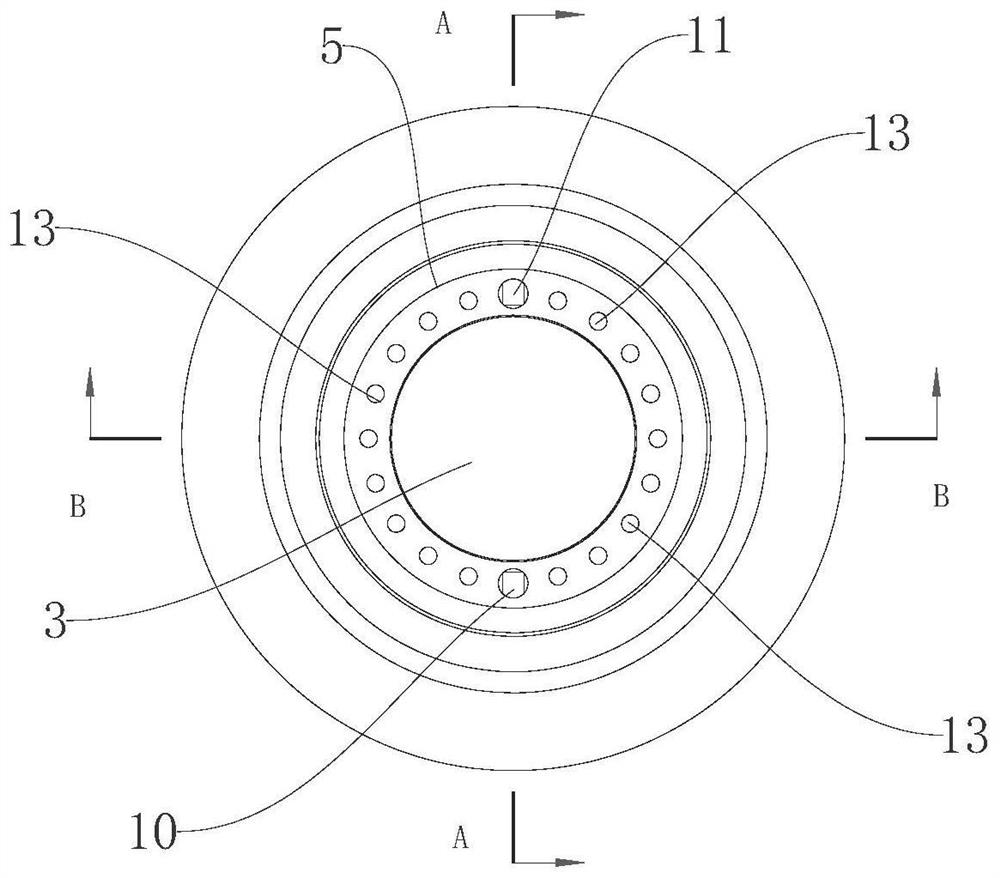

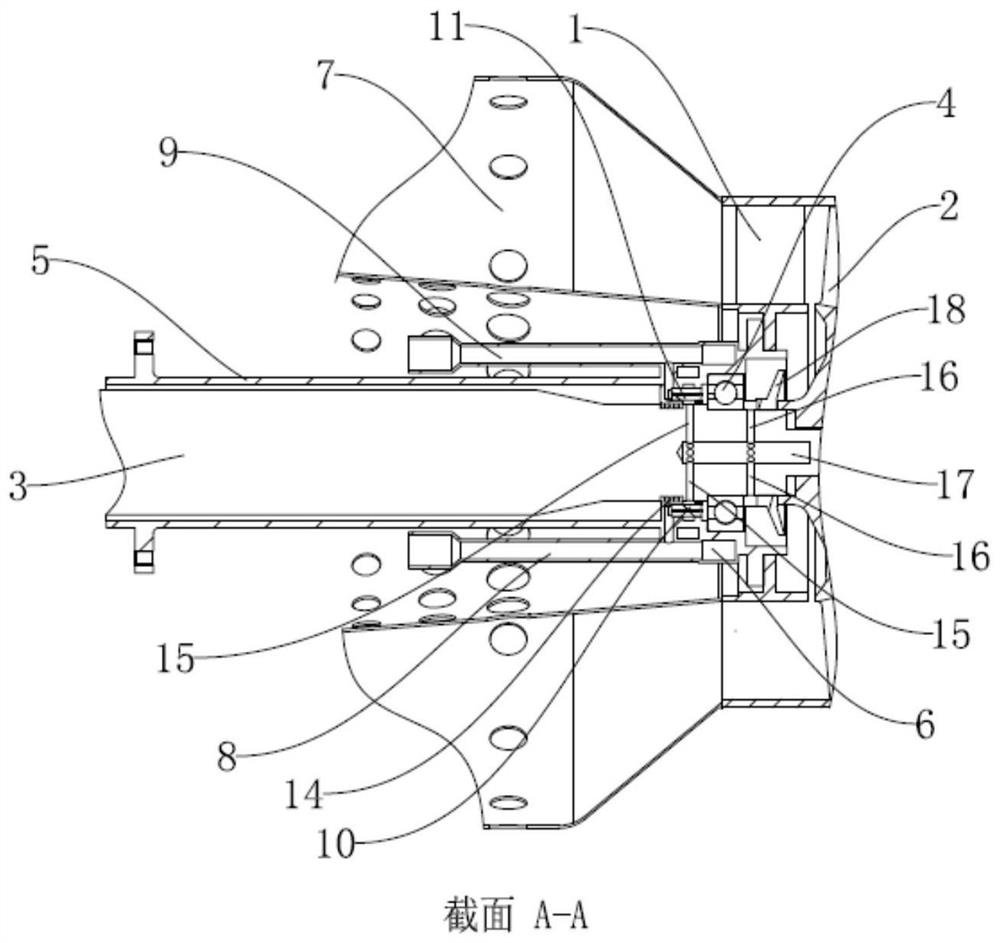

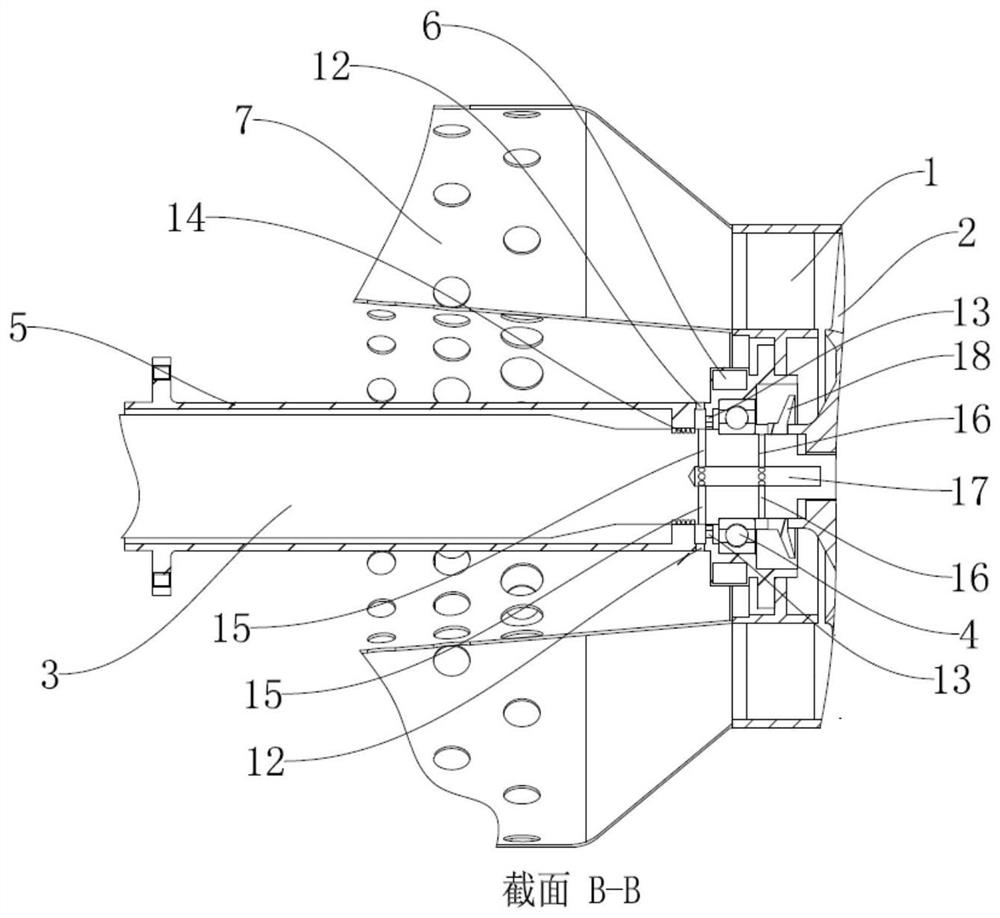

[0015] Example: Figure 1 - Figure 3As shown, a small vortex engine, a bearing cooling structure, a small vortex engine including a turbine stator 1, a turbine rotor 2, a spindle 3, a bearing 4, a bearing support 5, a fuel tube 6, a combustion chamber 7, an oil pipe 8 And the oil pipe 9, the bearing support 5 passes through the combustion chamber 7, and the main shaft 3 passes through the bearing support 5 and is mounted on the bearing support 5 through the bearing 4, and the turbine rotor 2 is mounted on the main shaft 3 and is located at the right of the bearing 4. On the side, the turbine stator 1 is mounted on the bearing support 5, the turbine stator 1 is located on the left side of the turbine rotor 2 and the right side of the bearing 4, and the fuel loop 6 is mounted on the bearing support 5 and located outside the bearing support 5, bearing 4 or all in the inner ring of the fuel loop 6, that is, the fuel loop 6 and the bearing 4, the fuel loop 6, the bearing support 5, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com