Pressure gauge movement and working method thereof

A working method and pressure gauge technology, which is applied in the measurement of fluid pressure, fluid pressure measurement through mechanical components, elastic deformation gauge fluid pressure measurement, etc., can solve the movement prone to shaking, pressure gauge measurement error, low efficiency, etc. problems, to achieve high assembly efficiency, avoid damage, and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

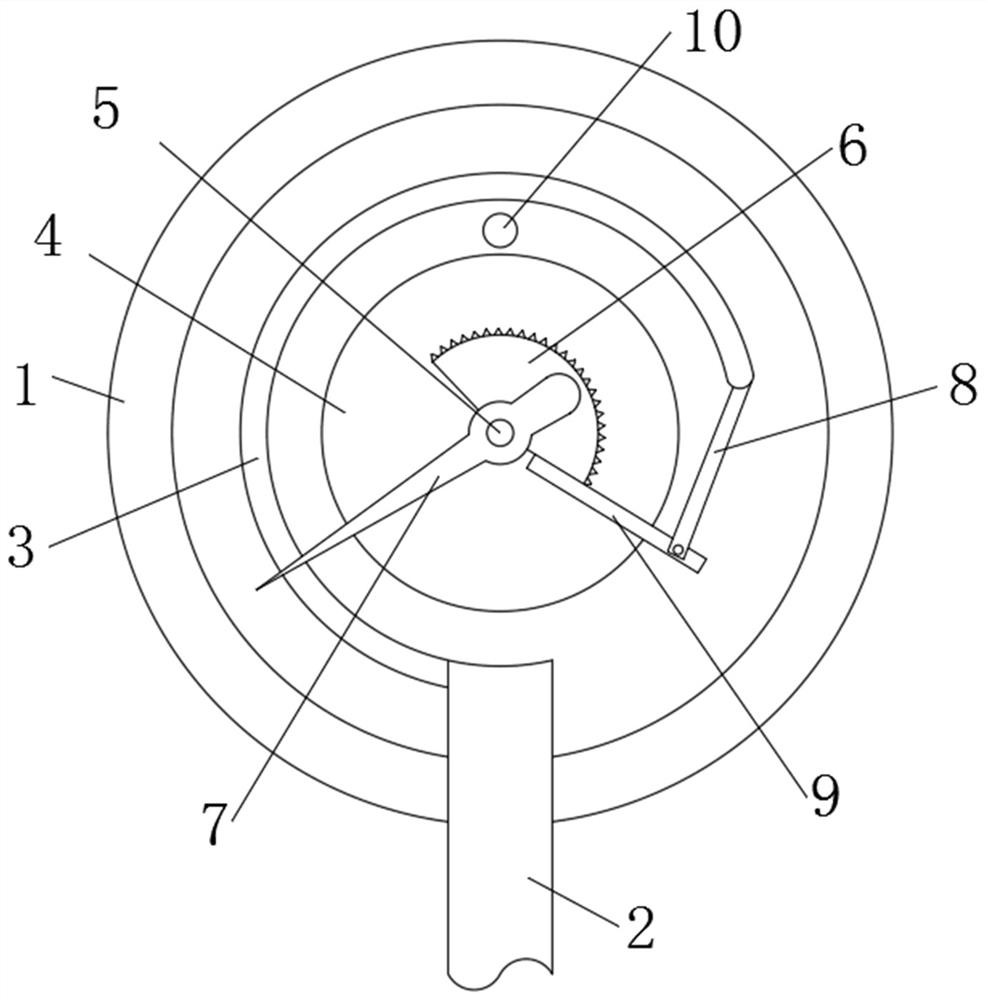

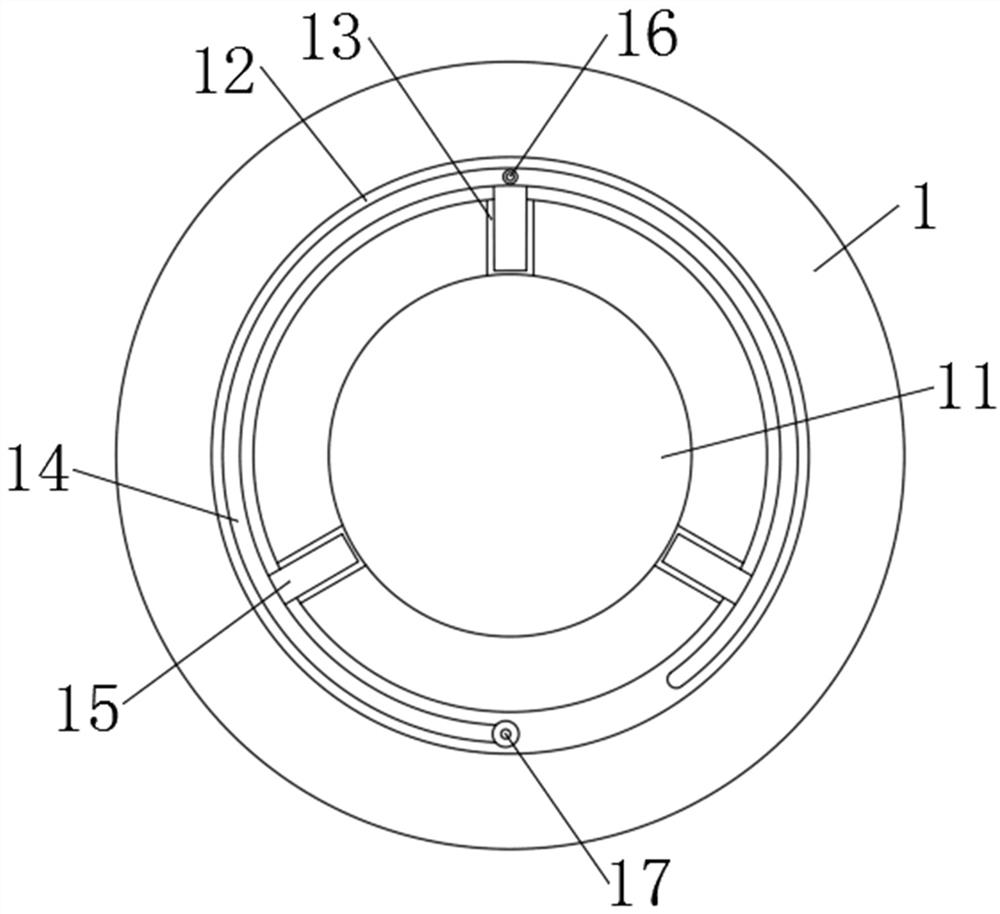

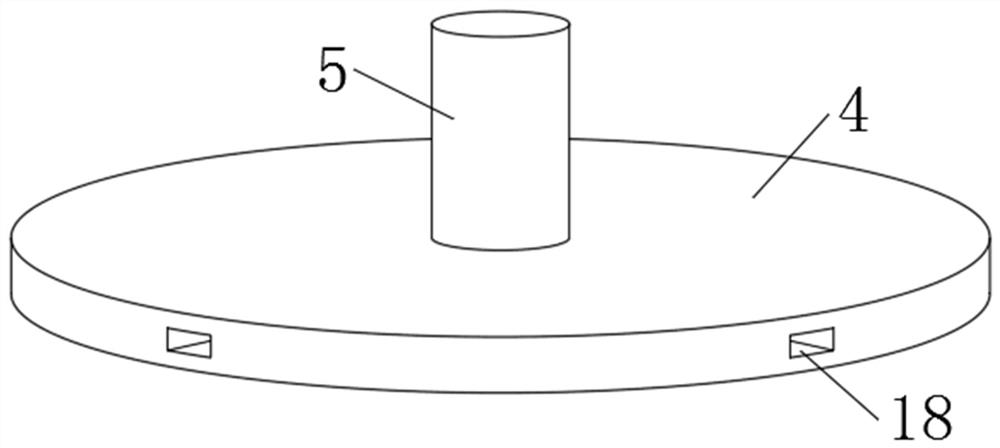

[0027] Such as Figure 1-5 As shown, a pressure gauge movement includes a housing 1, the bottom of the inner wall of the housing 1 is provided with a mounting groove 11, the inside of the mounting groove 11 is provided with a bottom plate 4, and the inside of the housing 1 is provided with a first cavity 12 And the second cavity 13, the first cavity 12 is circular, the second cavity 13 communicates with the first cavity 12 and the installation groove 11, the inside of the first cavity 12 is placed with an air bag 14, the second cavity 13 The inside of the airbag 14 is placed with a board 15, and the side of the airbag 14 near the installation groove 11 is fixedly connected with the board 15. The top of the airbag 14 is fixedly equipped with an inflation valve 16, and the tail of the airbag 14 is fixedly installed with an air supply valve 17. The installation groove 11 has the same shape and size as the bottom plate 4.

[0028] In this embodiment, the side of the bottom plate ...

Embodiment 2

[0034] Such as Figure 1-5 As shown, a pressure gauge movement includes a housing 1, the bottom of the inner wall of the housing 1 is provided with a mounting groove 11, the inside of the mounting groove 11 is provided with a bottom plate 4, and the inside of the housing 1 is provided with a first cavity 12 And the second cavity 13, the first cavity 12 is circular, the second cavity 13 communicates with the first cavity 12 and the installation groove 11, the inside of the first cavity 12 is placed with an air bag 14, the second cavity 13 The inside of the airbag 14 is placed with a board 15, and the side of the airbag 14 near the installation groove 11 is fixedly connected with the board 15. The top of the airbag 14 is fixedly equipped with an inflation valve 16, and the tail of the airbag 14 is fixedly installed with an air supply valve 17. The installation groove 11 has the same shape and size as the bottom plate 4.

[0035] In this embodiment, an intake pipe 2 is installed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com