Lifting belt fatigue detection equipment

A technology of fatigue detection and slings, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of insufficient comprehensive detection and achieve the effect of fatigue testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

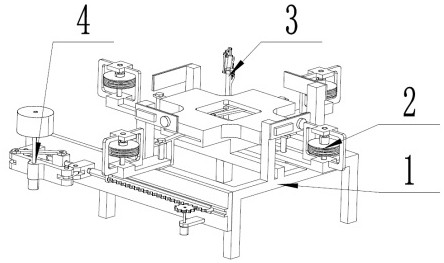

[0019] Example: Reference figure 1 A lifting belt fatigue detection device shown in -6, wherein the fatigue detection device 2, the damage detection device 3 and the adjustment device 4 are all fixedly arranged on the frame 1.

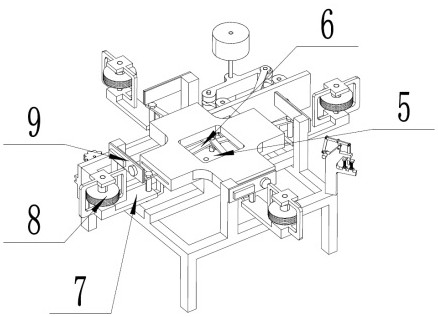

[0020] refer to figure 2 as well as Figure 4 In the fatigue detection device 2 shown, the fatigue detection power source 10 is fixedly arranged on the frame 1, the fatigue detection power source 10 is fixedly connected to the eccentric wheel 5, the eccentric wheel 5 is connected to the fatigue detection assembly, and the fatigue detection assembly is provided with 4 groups .

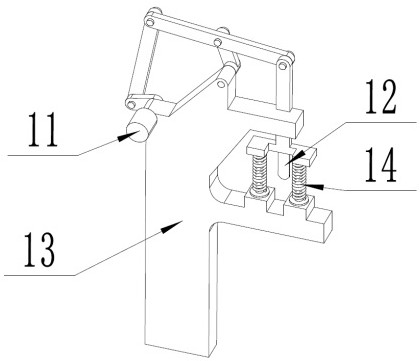

[0021] refer to figure 2 In the fatigue detection assembly shown, the first end of the driving link 6 is fixedly arranged on the eccentric wheel 5, the second end of the driving link 6 is fixedly arranged on the connecting plate 7, and the connecting plate 7 is slidably arranged on the frame 1. The sling roller 8 is rotated on the plate 7, the sling roller 8 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com