Copper bar assembly and electronic equipment

A technology for electronic equipment and components, applied in the direction of changing equipment structural components, circuits, contact components, etc., can solve problems such as mutual interference and uneven current flow in parallel branches, and achieve the effect of improving current sharing and reducing mutual influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

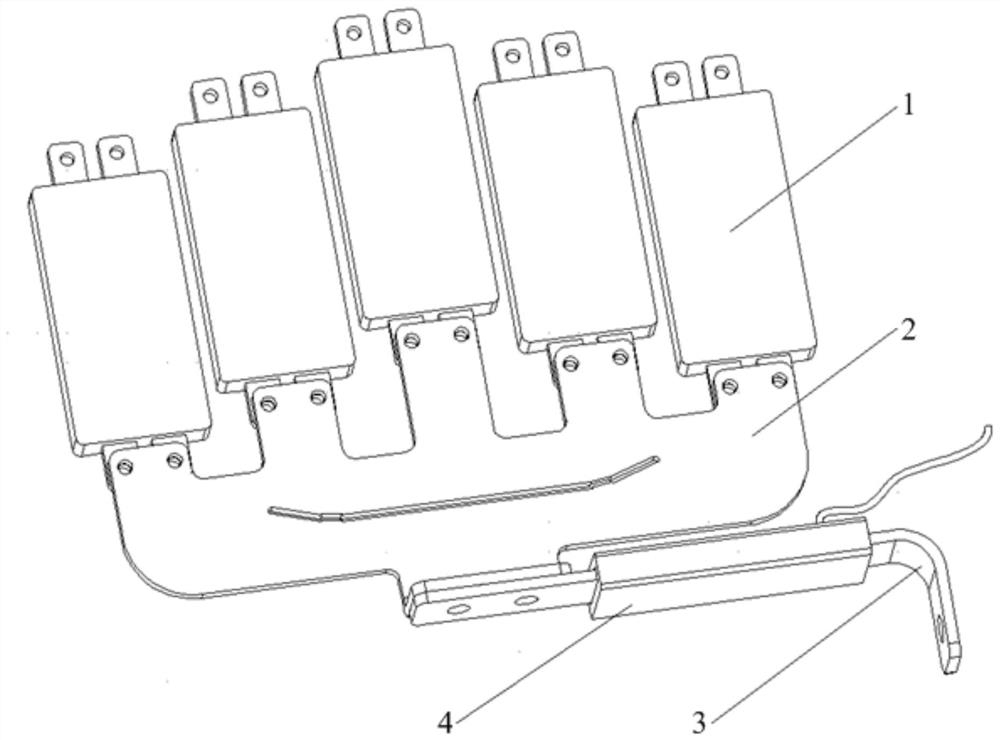

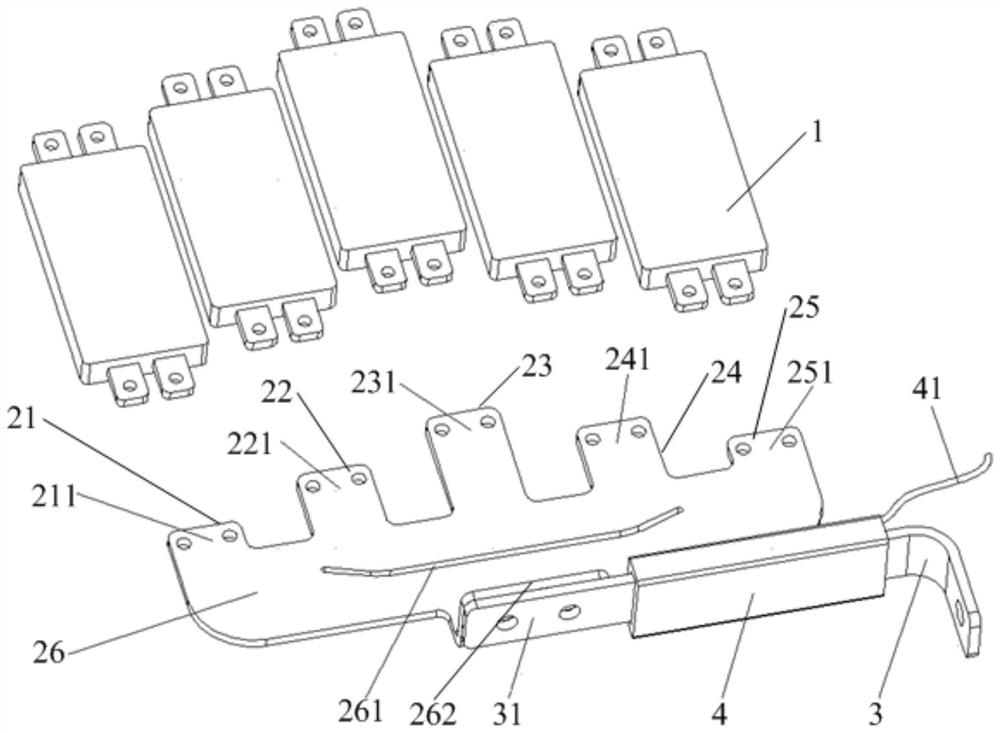

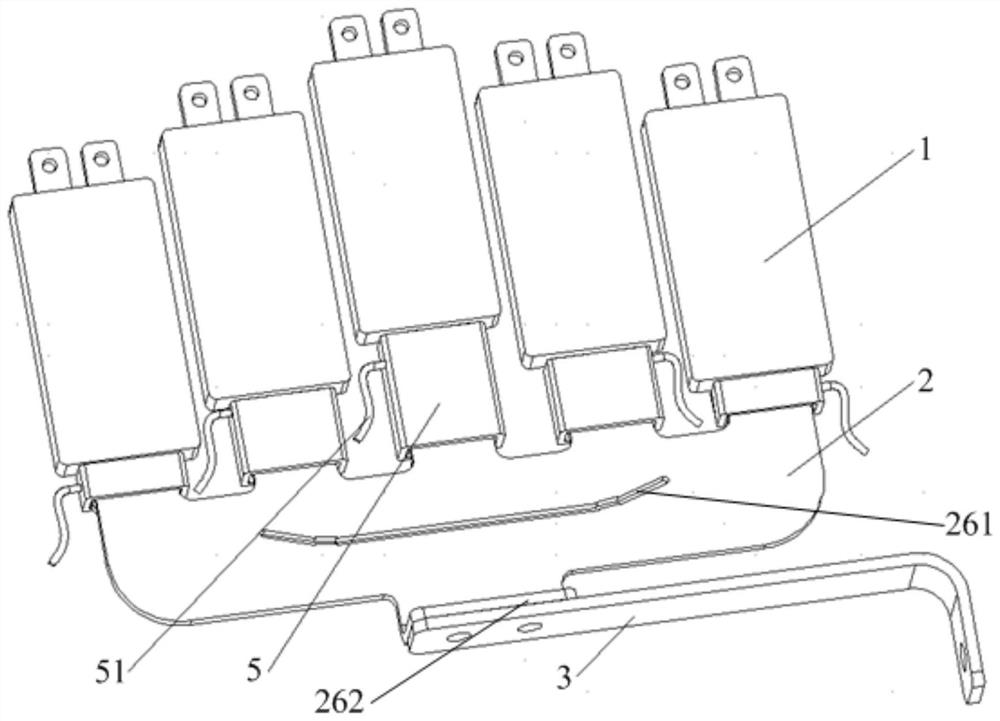

[0031] like Figure 1-6 As shown, the copper row assembly provided by the embodiment of the present invention includes a first copper row 2 and a second copper row 3, and the first copper row 2 includes a first copper row main body 26 and at least two unparalleled a copper row main body 26. The pin, the first copper row main body 26 is connected to the second copper row 3. It will be appreciated that any two pins are arranged in parallel.

[0032] The above copper discharge assem...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap