Insulating fireproof cable trough box

A fire-resistant cable and slot box technology, used in electrical components, springs/shock absorbers, vibration suppression adjustment, etc., can solve the problems of cable winding, poor shock resistance, cable danger, etc., to improve installation efficiency, improve safety, and safety. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

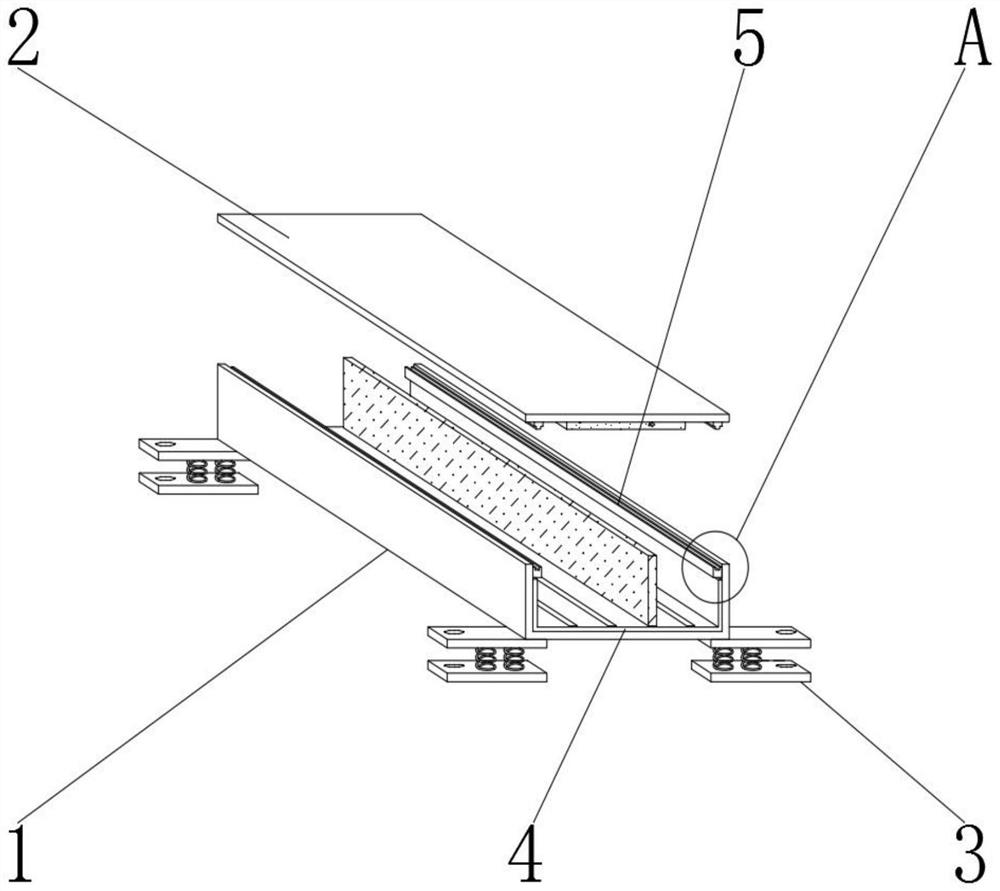

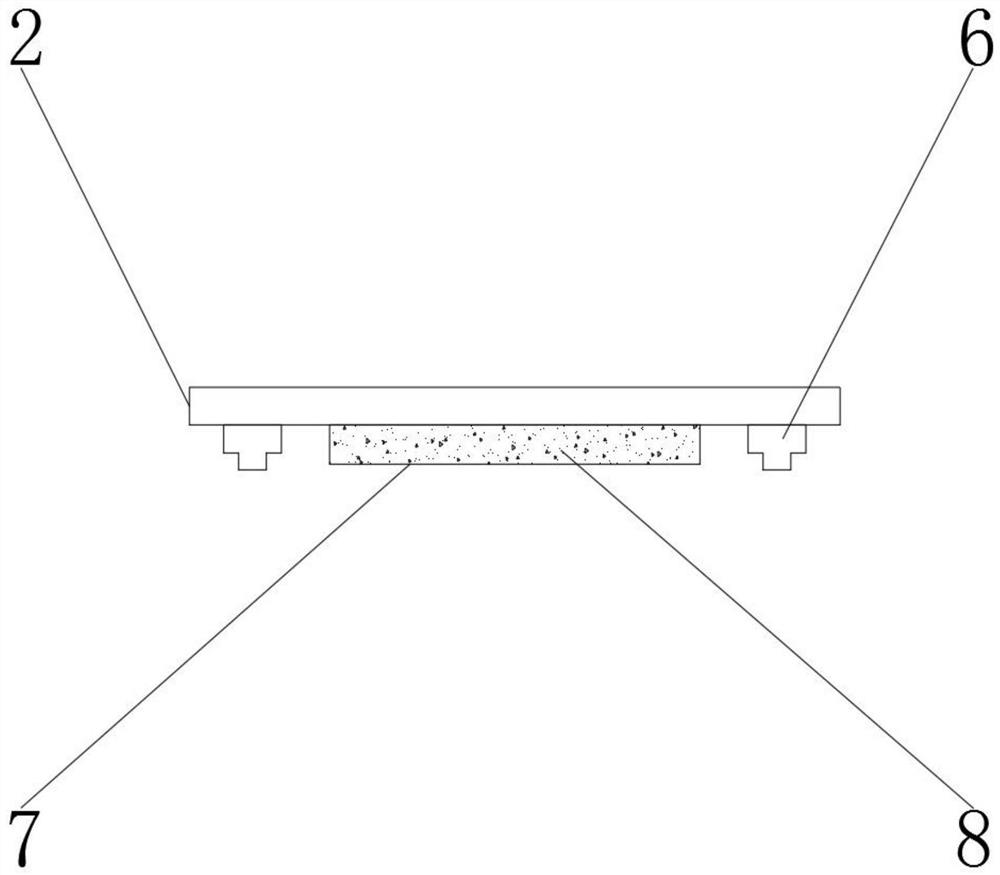

[0022] Such as Figure 1-2 As shown, an insulating fire-resistant cable trough box includes a bottom box 1 and an upper box cover 2, the bottom box 1 is located below the upper box cover 2, and the outer surface of the lower end of the bottom box 1 is provided with a fixing mechanism 3, and the bottom box The middle part of the box 1 is provided with a protective mechanism 4, the inner surface of both sides of the bottom box box 1 is provided with a concave magnetic strip 5, and the outer surface of the lower end of the upper box cover 2 is provided with a convex iron strip 6 and a fireproof airbag bag 7. Iron bar 6 is positioned at the both sides of fireproof airbag bag 7, and the interior of fireproof airbag bag 7 is provided with carbon dioxide 8.

Embodiment 2

[0024] On the basis of Embodiment 1, such as image 3 As shown, the fixing mechanism 3 includes an upper fixing piece 301, a spring 302, a lower fixing piece 303, a No. 1 screw hole 304 and a No. 2 screw hole 305, the spring 302 is located on the lower end outer surface of the upper fixing piece 301, and the lower fixing piece 303 is located On the outer surface of one end of 302, the No. 1 screw hole 304 is located in the middle of the upper fixing piece 301, the second screw hole 305 is located in the middle of the lower fixing piece 303, and the outer surface of the lower end of the upper fixing piece 301 is welded to the other end outer surface of the spring 302. , the outer surface of one end of the spring 302 is welded to the upper outer surface of the lower fixing piece 303, the number of springs 302 is two groups, the size of the first screw hole 304 is the same as the size of the second screw hole 305, and the first screw hole 304 It is opposite to the No. 2 screw hol...

Embodiment 3

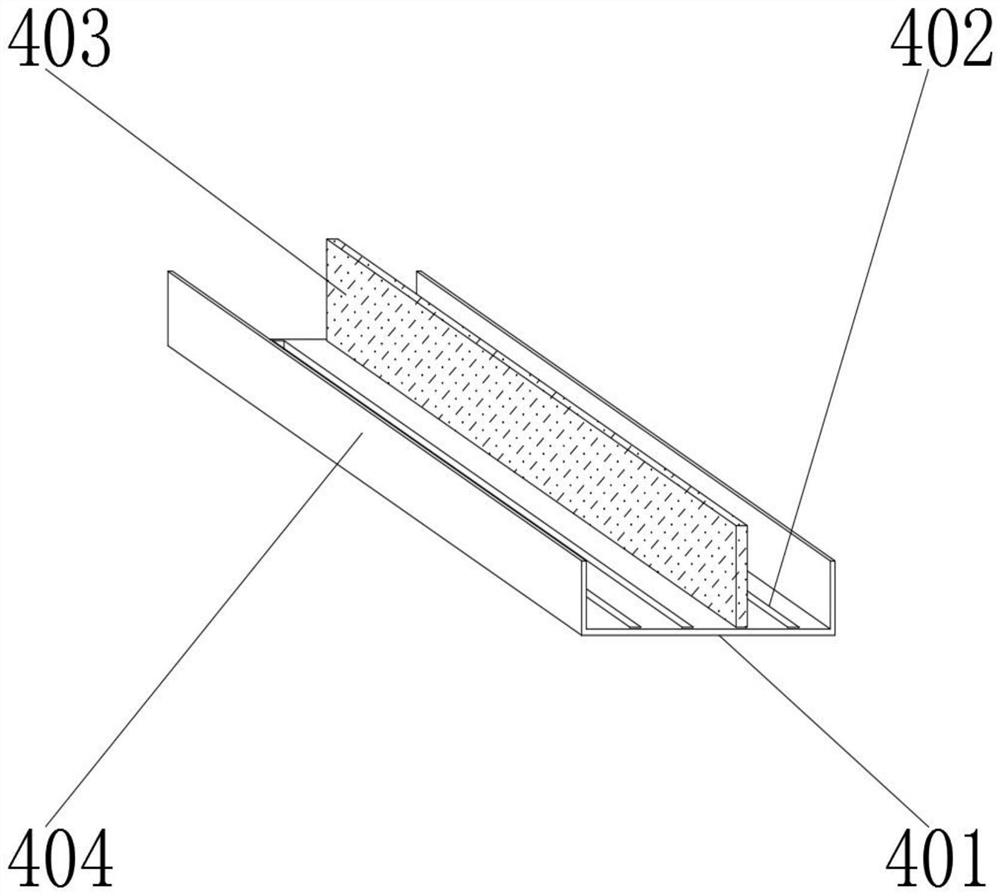

[0026] On the basis of Embodiment 1, such as Figure 4 As shown, the protective mechanism 4 includes a bottom plate 401, a connecting groove 402, a partition plate 403 and a side plate 404, the connecting groove 402 is located in the middle of the bottom plate 401, the partition plate 403 is located in the middle of the connecting groove 402, and the side plate 404 is located in the bottom plate The outer surface of the upper end of 401, the bottom plate 401 and the side plate 404 are integrally formed, the connecting groove 402 is opened in the middle of the bottom plate 401, the number of connecting grooves 402 is four groups, and the partition plate 403 is detachable from the bottom plate 401 through the connecting groove 402 connection, the separating plate 403 is made of glass fiber, the bottom plate 401 and the side plate 404 are made of insulating rubber, and the protective mechanism 4 can separate different types of cables through the separating plate 403 during use. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com