Atomizing core and atomizer

An atomizing core and atomizer technology, which is applied in the field of atomizers, can solve problems such as difficult positioning and complicated processes, and achieve the effects of good atomization effect, increasing atomization area, and improving user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

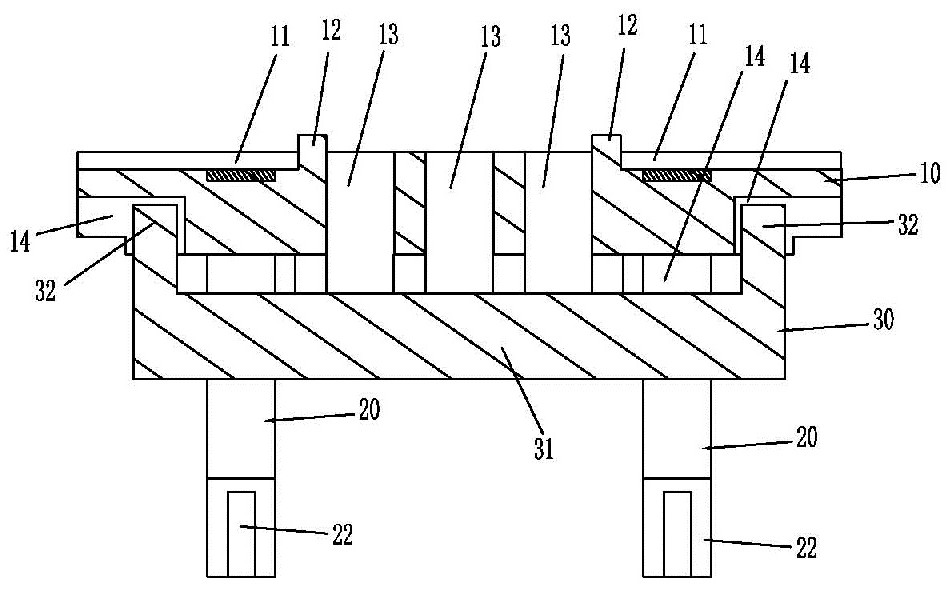

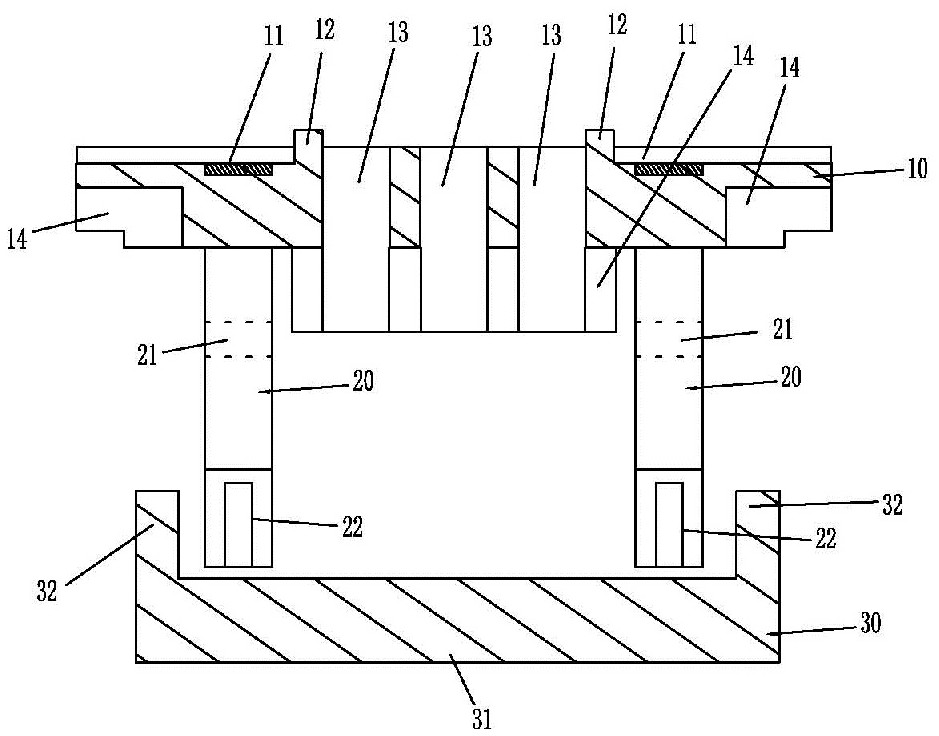

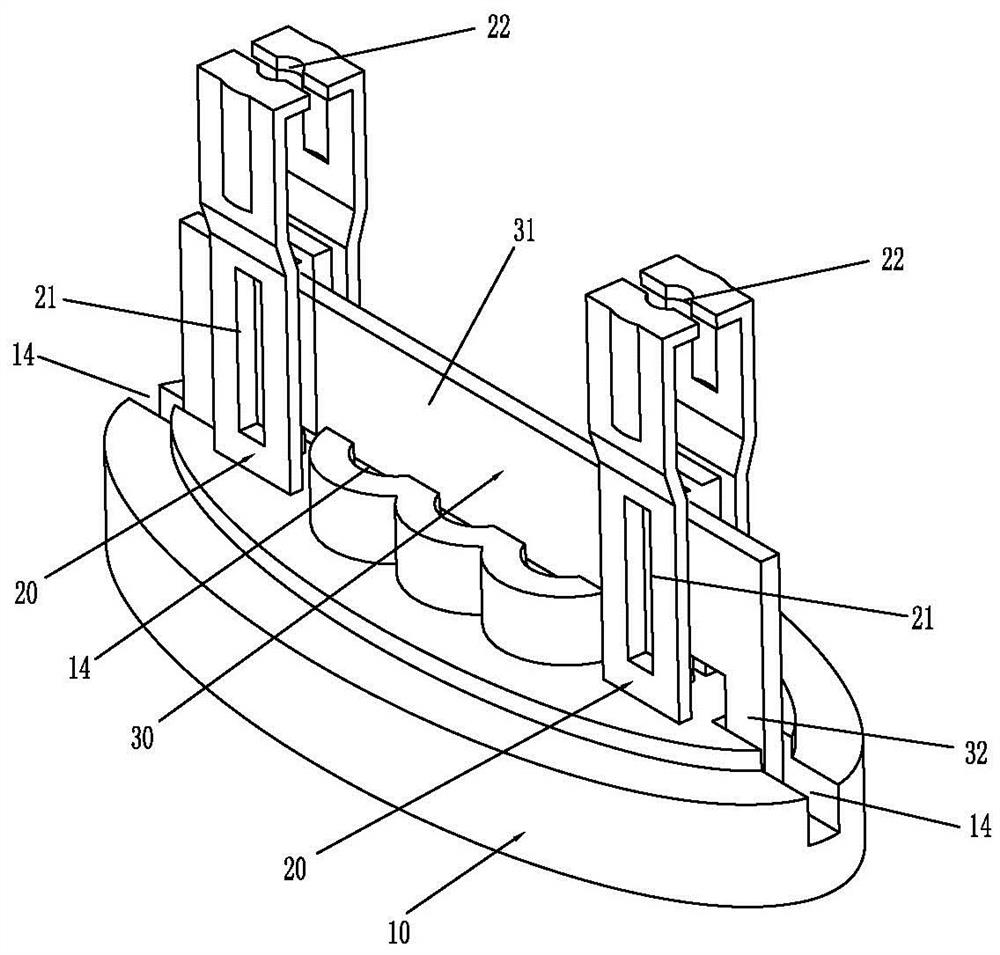

[0075] Please refer to Figure 1 to Figure 32 As shown, it shows the specific structure of the embodiment of the present invention.

[0076] First, please refer to Figure 1 to Figure 8 As shown, it shows an atomizing core, including a liquid conducting element 10, a conductive sheet 20 and an atomizing element 30; wherein:

[0077] The liquid guide element 10 adopts microporous material and utilizes capillary phenomenon to conduct liquid; the liquid guide element 10 is provided with a ventilation groove 11, a liquid blocking bone 12, an atomized gas cooling hole 13, and a liquid guide groove 14. The atomized gas cooling hole 13 runs through the liquid guide element 10 up and down, the vent groove 11 is arranged on the top of the liquid guide element 10 and is located on the outer periphery of the upper end of the atomized gas cooling hole 13, and the liquid blocking bone 12 is separated from the atomized gas cooling hole. Between the upper end of the hole 13 and the ventila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com