Locking device capable of adjusting nailing force of electric nail gun

A locking device and adjustable technology, applied in nailing tools, manufacturing tools, etc., can solve problems such as wear and tear, and achieve the effects of ensuring nailing quality, saving use costs, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

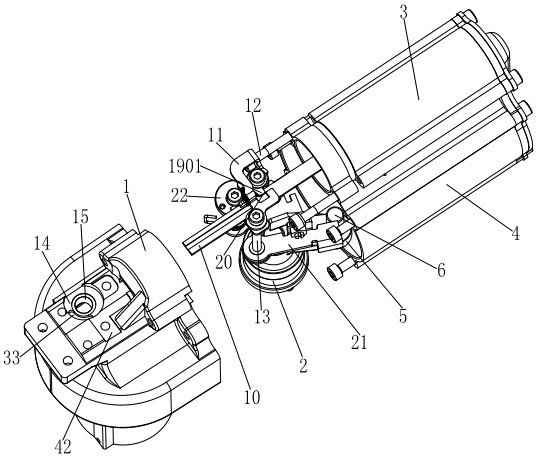

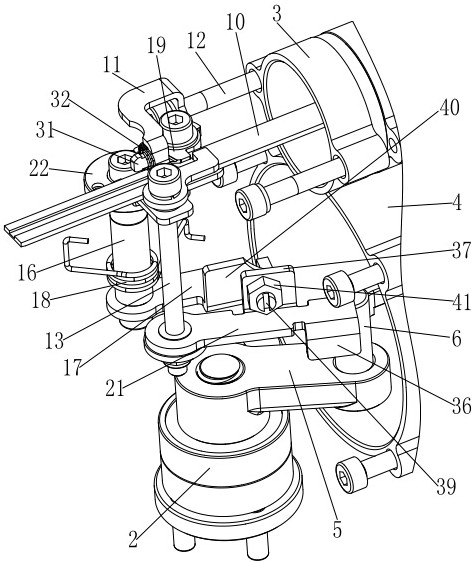

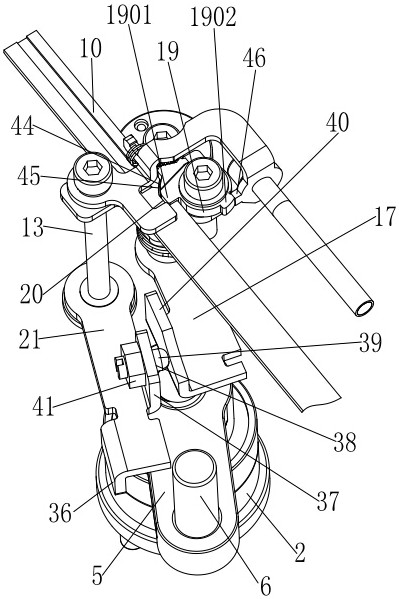

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0028] see Figure 1 to Figure 9 , the present invention provides a locking device capable of adjusting the nailing force of an electric nail gun, comprising a power box 1, a driving motor arranged in the power box 1, an upper cylinder 3 and a lower cylinder 4 arranged on the right side of the power box 1, and a lower cylinder 4 arranged on the right side of the power box 1. The cylinder 4 is located directly below the upper and lower cylinders 4, and the drive motor is connected to the connecting arm 5 through the reduction mechanism 2. The end of the connecting arm 5 is provided with an eccentric shaft 6, and the lower cylinder 4 is provided with a lower piston 7, which is provided with a corresponding The hinged piston arm 8 is connected to the eccentric shaft 6, the upper cylinder 3 is provided with an upper piston 9, and the center of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap