impact device

A technology of impact device and guide part, which is applied in the direction of impact tools, light impact tools, manufacturing tools, etc., can solve the problems of uneven impact force, damage, crank pin damage, etc., to ensure uniform movement direction, force transmission, Ease of exit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

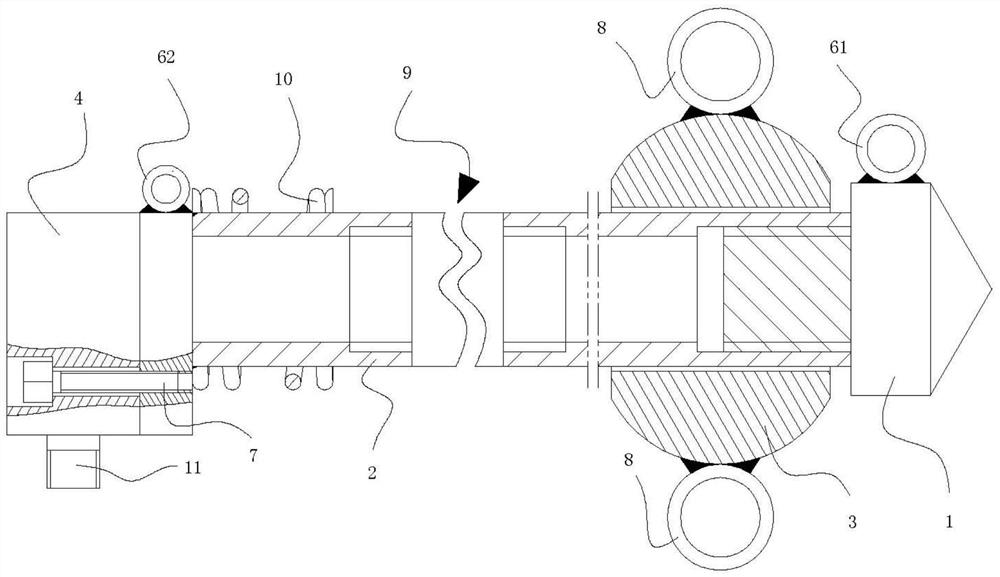

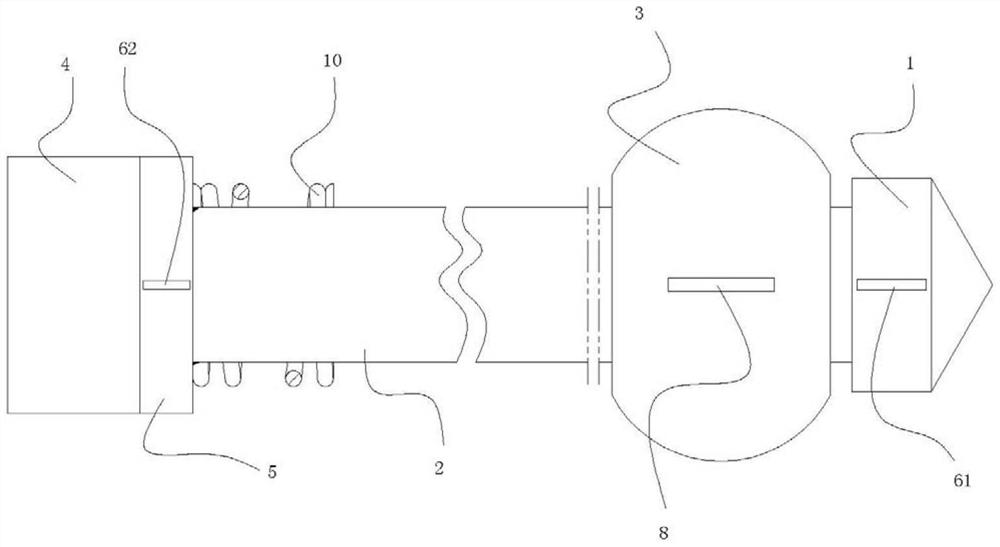

[0061] like figure 1 , figure 2 As shown, the impact device in this embodiment includes a center-of-gravity adjustment part that connects the guide part and the pressure supply part. When facing downwards, the center of gravity of the device is set along the direction of gravity. With the impact device introduced in this embodiment, the setting of the center of gravity adjustment part can further ensure the stability of the center of gravity of the device. During the sliding process of the sliding part, it is inevitable that there will be hidden dangers of changes in the direction of force applied by the user or changes in the position of the center of gravity of the device. The design of the center of gravity adjustment part is added to the device introduced in the present invention, so that the center of gravity of the device is obviously biased towards the lower side of the device, which is consistent with the direction of gravity. Similarly, even if the center of gravit...

Embodiment 2

[0065] like figure 1 , figure 2 As shown, the difference between the impact device in this embodiment and the above embodiments is that: the impact device includes a first positioning portion for positioning the tip, and the first positioning portion is arranged on one side of the tip. Preferably, the first positioning part is arranged on the other side of the center of gravity of the center of gravity adjustment part relative to the tip part. Then the projection of the connection line between the first positioning part and the center-of-gravity adjusting part in the vertical direction is the vertical direction, which is the same as the direction of gravity. The first positioning part suspends the device above the device, and the center-of-gravity adjusting part adjusts the direction of suspension below, thereby realizing the positioning and position adjustment of the device.

[0066] Further preferably, the first positioning part in this embodiment is a ring structure, whi...

Embodiment 3

[0071] like figure 1 , figure 2 As shown, the difference between the impact device in this embodiment and the above embodiment is that the impact device includes an operating part for controlling the sliding of the sliding part, the operating part is connected to the sliding part, and the number of operating parts is at least two, at least two The operating parts are arranged oppositely; the operating part is a ring structure.

[0072] Through the impact device introduced in this embodiment, the design of the operation part can assist the user to control the sliding part more conveniently. The number and setting positions of the operating parts can be designed and adjusted according to the needs of users. Preferably, the angle range between the operating parts is within the range of 60-180°. A rope can be connected to the operating part, which is convenient for the user to grasp the sliding part.

[0073] Further, the impact device in this embodiment includes a hydraulic t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com