Axle assembly for commercial vehicle and use method of axle assembly

A technology for commercial vehicles and vehicles, applied in the directions of axles, wheels, vehicle parts, etc., can solve the problems of increasing the user's vehicle maintenance cost, sliding phenomenon, tire eating, etc., to reduce abnormal tire wear phenomenon, and minimize the amount of movement interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The following examples help those skilled in the art to further understand the present invention, but do not limit the present invention in any form.

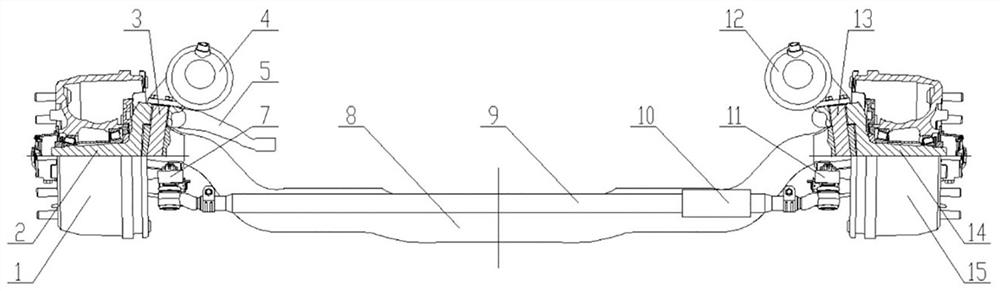

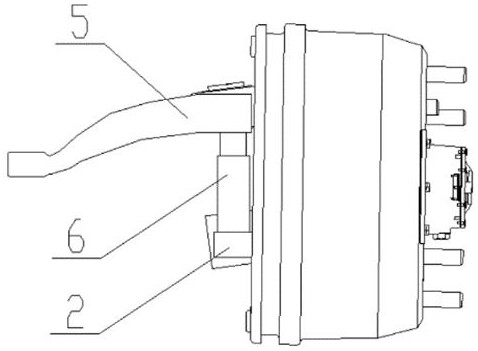

[0038] Such as figure 1 As shown, a commercial vehicle axle assembly is characterized in that it consists of a left wheel hub 1, a left steering knuckle 2, a left kingpin 3, a left brake drum 4, a steering knuckle arm 5, a steering knuckle arm expansion device 6, Left trapezoidal arm 7, I-beam 8, steering tie rod 9, steering hydraulic cylinder 10, right trapezoidal arm 11, right brake drum 12, right kingpin 13, right steering knuckle 14, and right wheel hub 15;

[0039] The left wheel hub 1 is installed on the left steering knuckle 2, the left wheel hub 1 and the left steering knuckle 2 are movably connected, and the left wheel hub 1 can rotate around the left steering knuckle 2;

[0040] The le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com