Tyre with heat radiation slot formed on the tyre shoulder for automobile

A heat dissipation groove and tire shoulder technology, which is applied in tire measurement, tire parts, tire tread/tread pattern, etc., can solve the problem of increased abnormal wear, lack of abnormal wear of the tread, and inability to effectively block the linkage of the tread, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

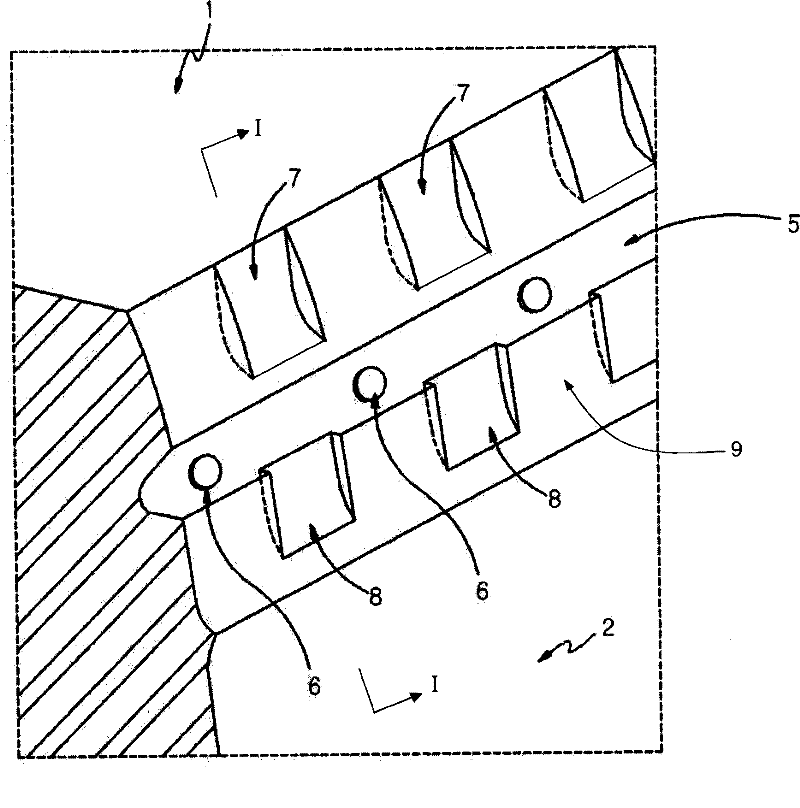

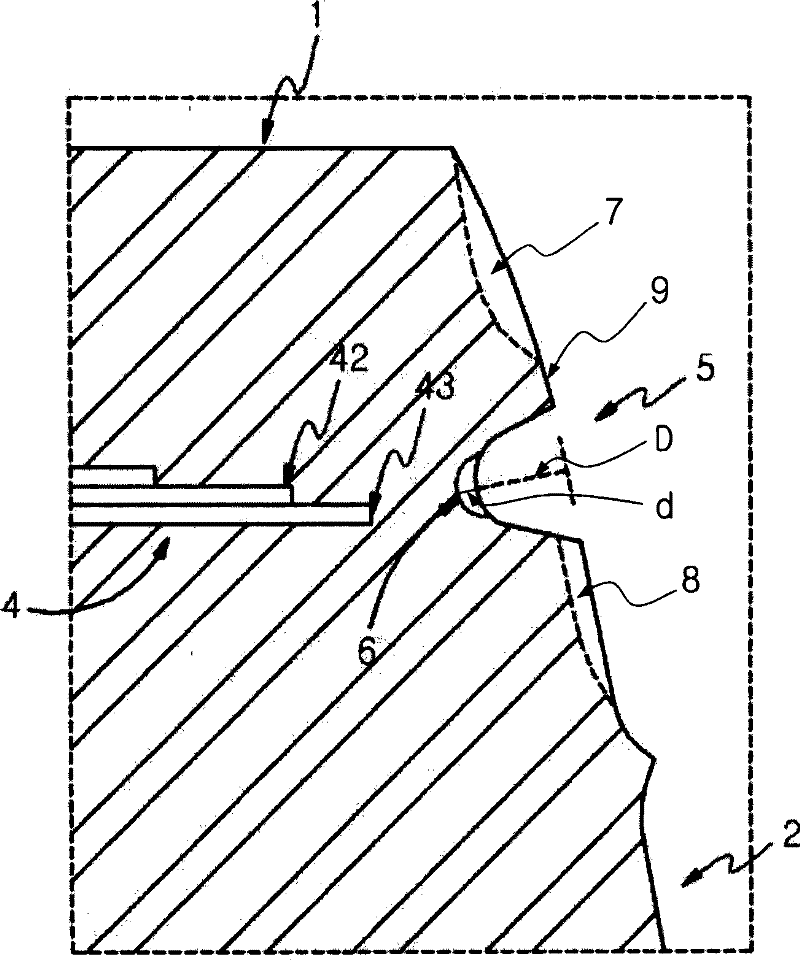

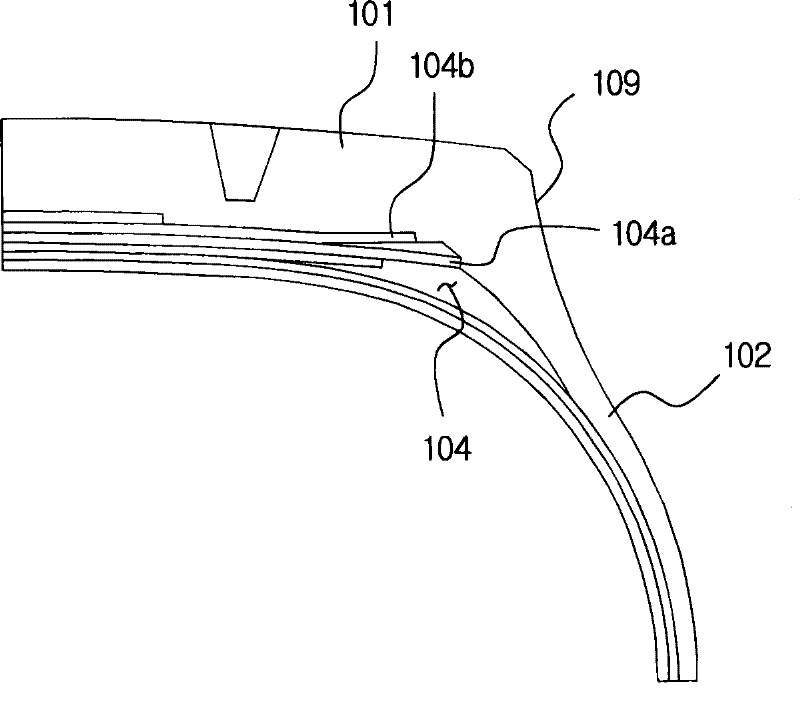

[0012] figure 1 It is a diagram showing an automobile tire having heat radiation grooves formed in the shoulders according to the present invention, and shows a partially cutaway tire of a part of a shoulder (9) connected to a tread (1) and a sidewall (2) in the tire stereogram, figure 2 yes figure 1 Line sectional view of I-I.

[0013] The automobile tire of the present invention is composed of a tread (1), a sidewall (2) and a bead portion, and on the inner bottom of the tread (1), there is provided a belt (42, 43) laminated The resulting belt (4), wherein grooves (5) are formed in the circumferential direction on the shoulders (9) apart from the edge of the belt (4), and further A plurality of heat dissipation holes (6) are formed at equal intervals, between the above-mentioned heat dissipation holes (6) and adjacent heat dissipation holes (6), and bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com