Trailer coupler with good mounting performance

A coupler and trailer technology, which is applied in traction connectors, vehicle parts, transportation and packaging, etc., can solve the problem of reducing the performance of the trailer coupler, and achieve the effect of improving the performance of the mount and avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

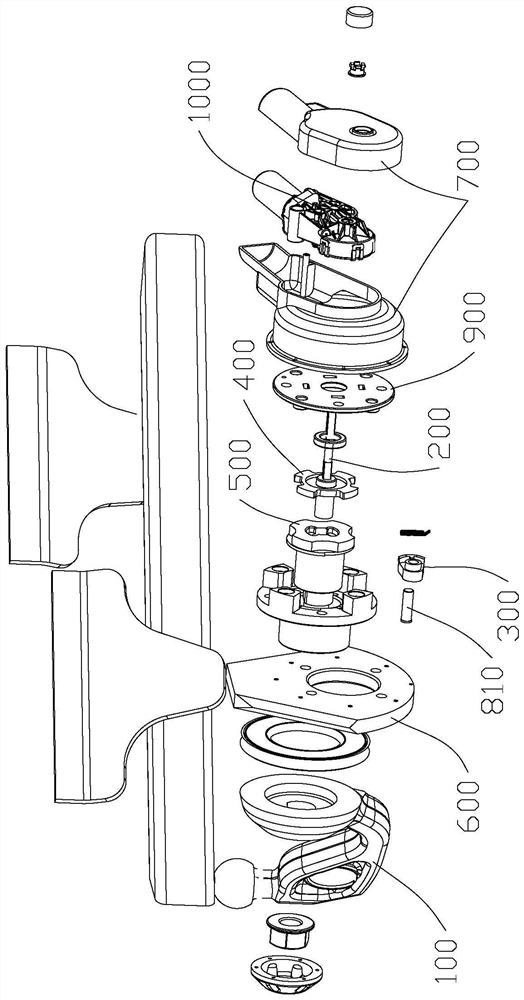

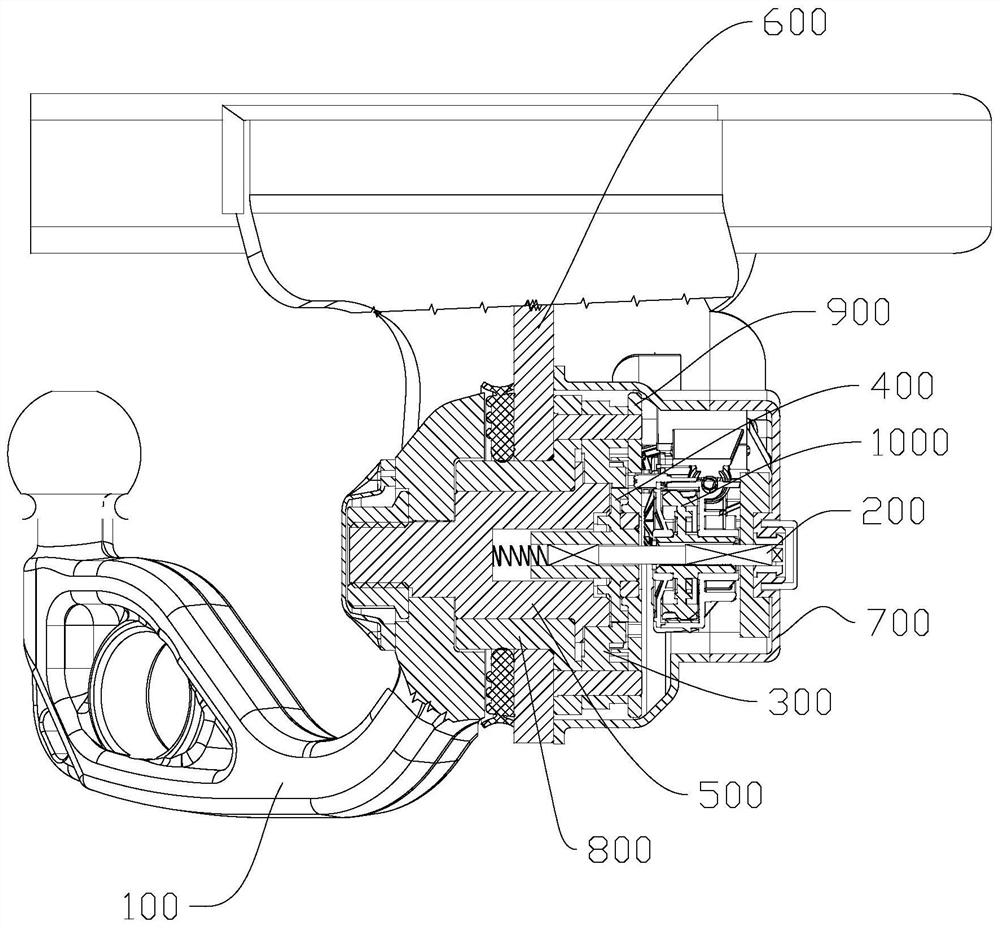

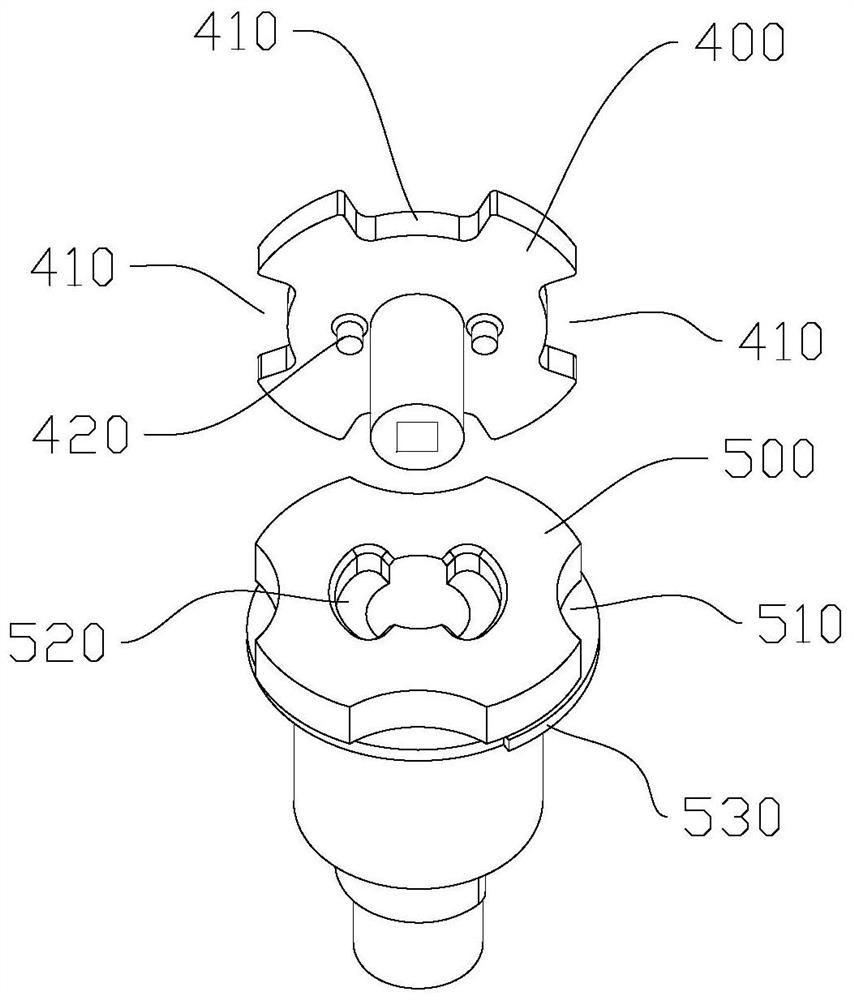

[0040] refer to Figure 1 to Figure 8 As shown, the trailer coupler in this embodiment includes a main body and a trailer hook 100, the main body is fixed on the anti-collision beam of the vehicle body, the main body includes a driving shaft 200, a locking member 300, a transmission disc 400 and a driven shaft 500, from The driving shaft 500 is connected with the tow hook 100 and rotates synchronously. The driving shaft 200 drives the transmission disc 400 to idle, so that the locking member 300 locks or unlocks the rotation of the driven shaft 500. When the locking member 300 unlocks the rotation of the driven shaft 500, The driving shaft 200 drives the driven shaft 500 to rotate through the transmission disc 400, so that the tow hook 100 can be switched between the folded position and the unfolded position. When the tow hook 100 is in the folded position or the unfolded position, the locking member 300 locks the turn.

[0041] In this embodiment, when the drive shaft 200 dr...

Embodiment 2

[0057] Such as Figure 9 As shown, compared with Embodiment 1, the difference of this embodiment is that teeth 320 are provided on the arc surface of the claw, and tooth grooves meshing with the teeth are provided on the outer peripheral side of the transmission disc 400, preferably the transmission disc 400 is a gear, and the tooth groove forms the driving groove 410 . Such a design can also push the pawl out of the locking groove 510 through the groove wall of the driving groove 410 .

Embodiment 3

[0059] Compared with Embodiment 1 and Embodiment 2, the difference of this embodiment is that no motor assembly is provided in the housing 700 in this embodiment, and in this case, one end of the drive shaft 200 extends out of the housing 700 In addition, the user can also drive the drive shaft 200 to rotate by turning the end of the drive shaft 200 protruding out of the housing 700 with a wrench or by hand, so that the tow hook 100 can be switched between the folded position and the unfolded position, thereby reducing the manufacturing cost of the product. Cost, but also to avoid the phenomenon that the product cannot be used normally due to electrical failure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com