Anti-bending straight rail groove

A rail groove and straight shape technology, which is applied in the field of grinding and processing, can solve the problems of bending deformation of straight rail grooves, easy deformation of straight rail grooves, poor compression resistance, etc., and achieve the effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

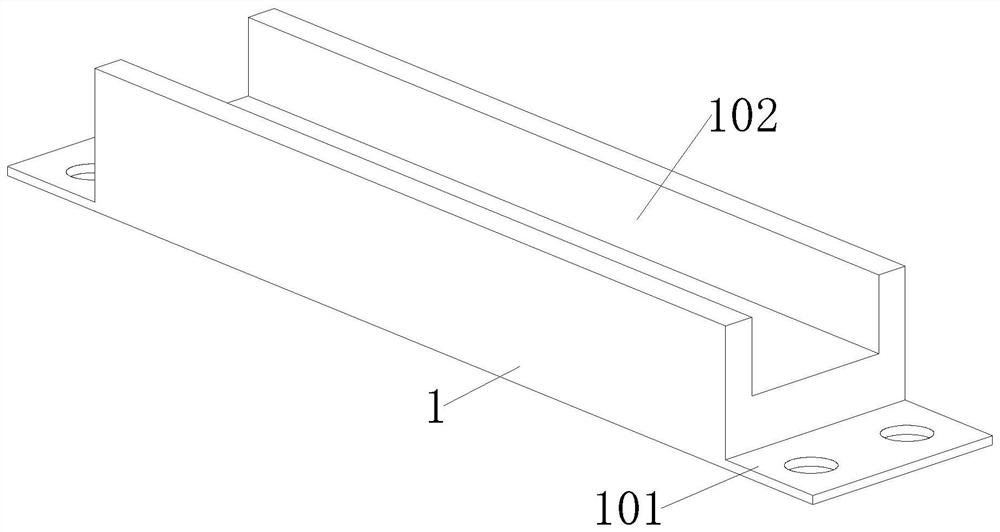

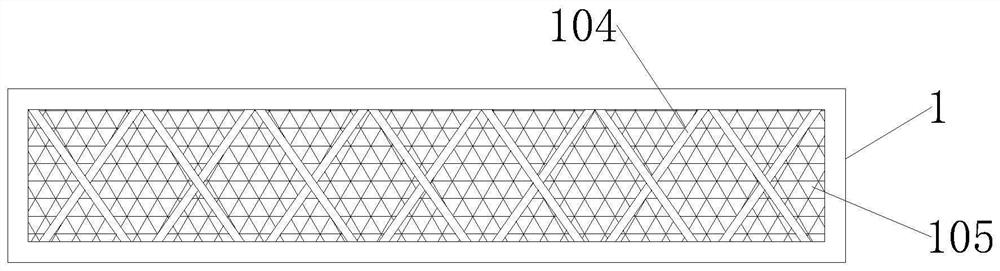

[0027] refer to Figure 1-7 , the present invention provides a bending-resistant straight rail groove, including a rail groove 1 and a mounting plate 101. The mounting plate 101 is provided with two pieces and fixed on the lower edges of the left and right ends of the rail groove 1 respectively. The plate 101 is convenient for the user to install the entire rail channel 1 at the designated installation position;

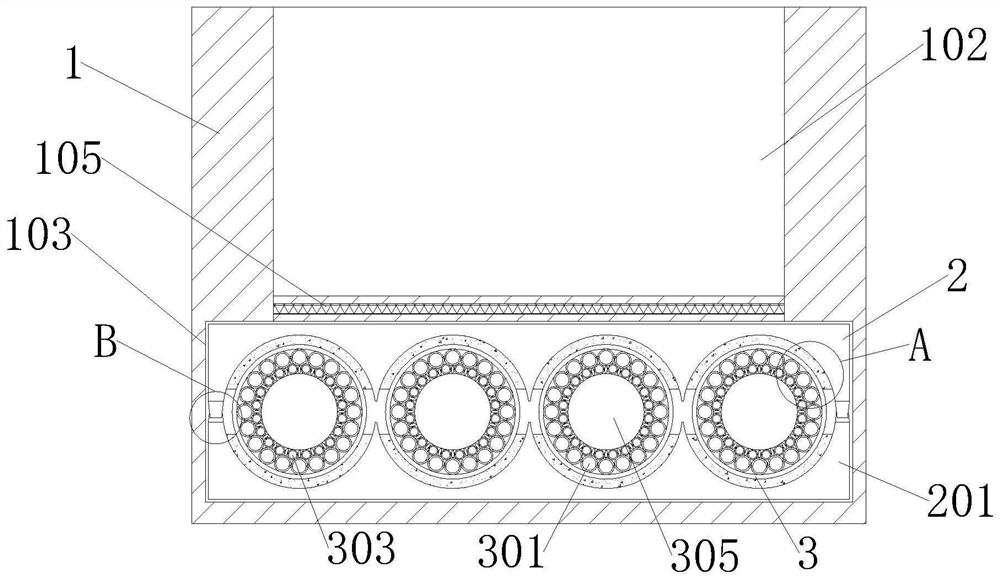

[0028] There is an inner cavity 103 at the bottom of the rail channel 1, and the upper and lower sides of the inner cavity 103 are respectively provided with an upper anti-compression plate 2 and a lower anti-compression plate 201, the lower surface of the upper anti-compression plate 2 and the upper surface of the lower anti-compression plate 201 are both There are four semi-circular grooves 202 corresponding to the upper and lower sides, and the inner walls of the semi-circular grooves 202 are fitted with extruded soft pads 203, and the front and rear side edges of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com