Detection tool for detecting friction torque between bearing sealing ring and outer ring

A technology of bearing sealing and friction torque, which is applied in the direction of mechanical bearing testing, measuring devices, torque measurement, etc., can solve the problems of unfavorable product design quality, affecting the use of bearings, and reducing the use effect of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

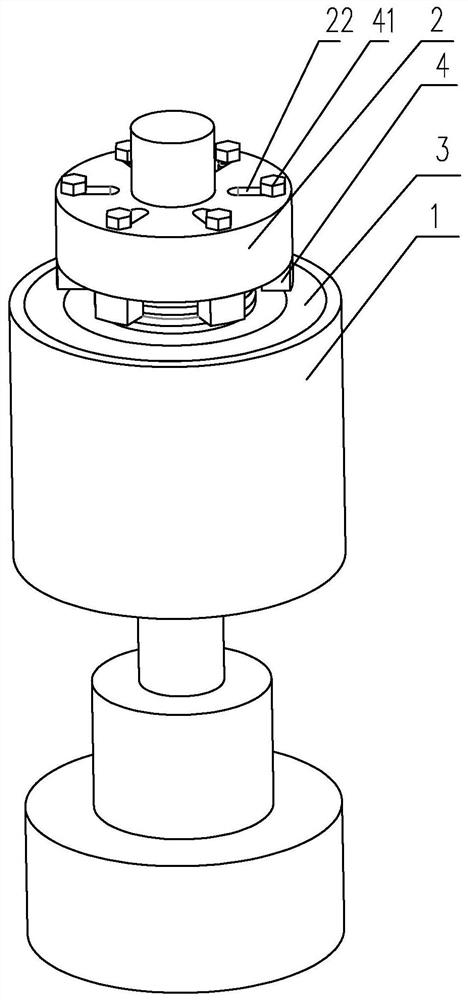

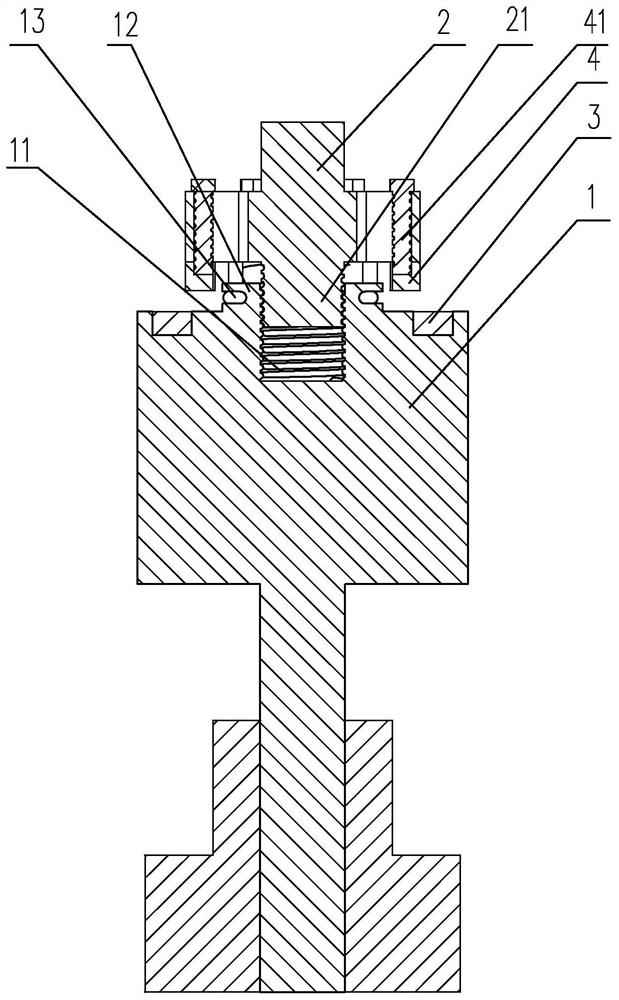

[0018] The embodiment of the detection tool for detecting the friction torque between the bearing sealing ring and the outer ring of the present invention is as follows figure 1 and figure 2 Shown: includes a base 1, one end of the base 1 is formed with a placement platform for placing the outer ring, a positioning hole 11 is opened at the center of the placement platform, and a pressing member 2 is fitted in the positioning hole 11, so that The pressing part 2 is provided with a fastening protrusion 21, and the fastening protrusion 21 is threadedly matched with the positioning hole 11, and the pressing part 2 is also provided with a ring along the circumference for resisting the sealing ring on the placement platform. Contradictions are raised 4. The beneficial effect of such setting is: setting in this way, the sealing ring is set at the position of the fastening protrusion 21, and then the outer ring to be tested is placed on the placement platform, and the pressing part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com