Industrial heating radiator painting equipment

An industrial technology for heat sinks, applied in the field of heat sink painting equipment, can solve the problems of secondary painting, uneven paint on heating heat sinks, and affecting the appearance of heating heat sinks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

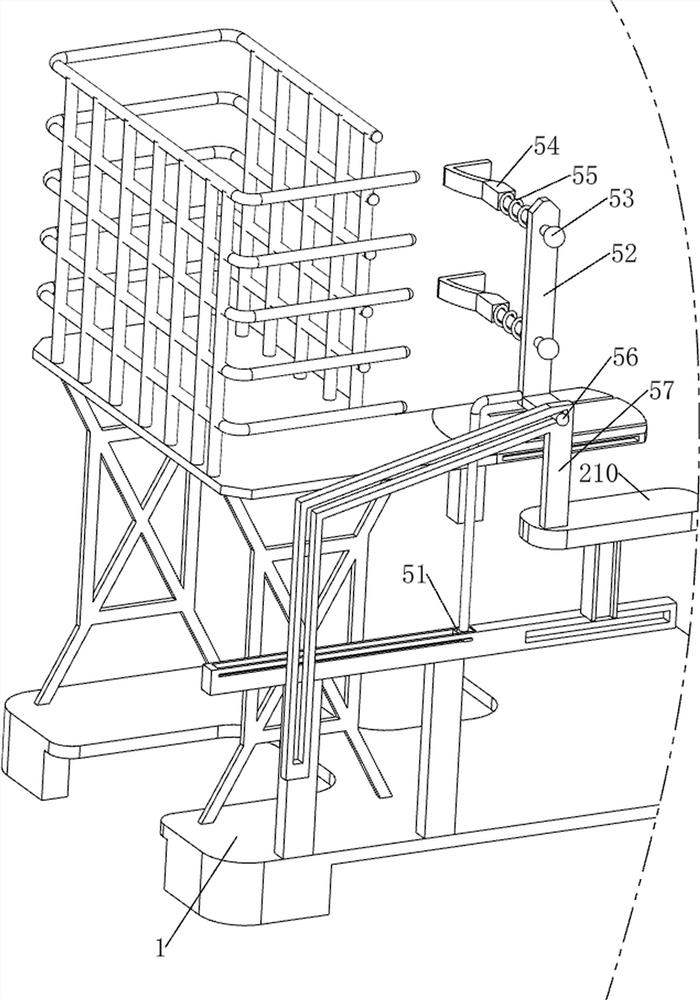

[0072] Industrial heating heat sink paint equipment, such as figure 1As shown, including the base 1, the rise mechanism 2 and the painting mechanism 3, the base 1 is provided with a spray mechanism 3 at the top of the rise mechanism 2.

[0073] When people need to laminate the heating tile, the industrial heating heat sink paint can first be placed on the pedestal 1, and the paint is poured into the paint mechanism 3, and then start the rise mechanism 2, the rise mechanism 2 moves the painting mechanism 3 upward movement so that the painting mechanism 3 can paint the heating heat sink, and when the rise mechanism 2 is moved downward, the painting mechanism 3 can be again refurbished. After the heat sink, when the rise mechanism 2 is reset down, the paint mechanism 3 stops paint on the heating heat sink, and then closing the raised mechanism 2.

Embodiment 2

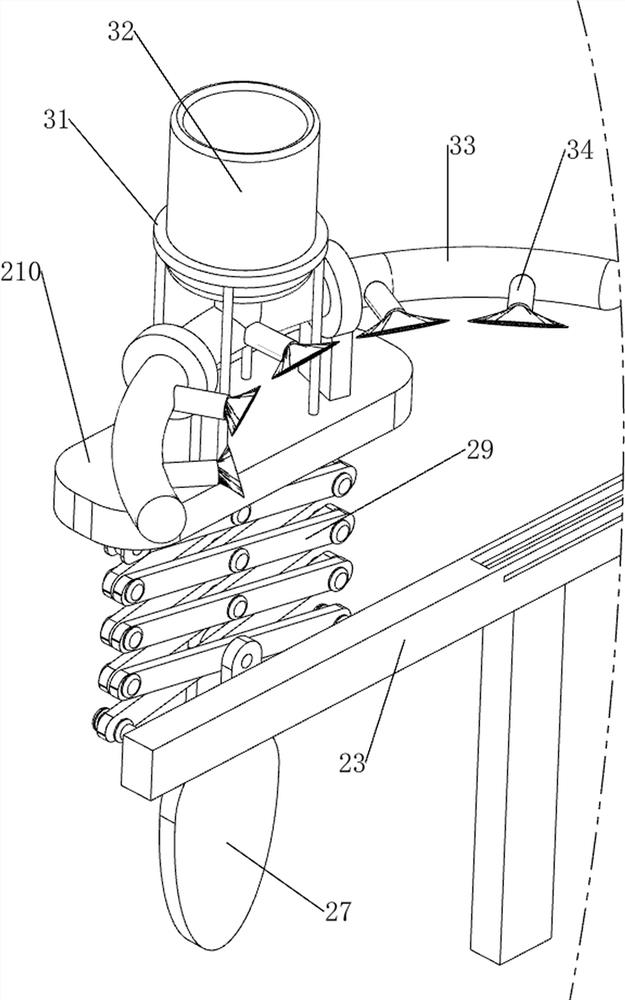

[0075] On the basis of Example 1, such as figure 2 and image 3 As shown, the rise mechanism 2 includes a first support frame 21, a motor 22, a first fixing block 23, a second fixing block 24, a housing 25, a rotating shaft 26, a cam 27, a top block 28, a folding frame 29, a second support. The frame 210 and the first slider 211, and the seat 1 are provided with a first support frame 21, and a motor 22 is attached to the top of the first support frame 21, and the first fixed block 23 is provided on the top of the base 1. The base 1 is provided with a second fixing block 24 on the upper right portion. The first support frame 21 is provided with a bearing housing 25, and the output shaft on both sides of the motor 22 is connected to the housing 25, respectively. There is a cam 27 in the outer side of the rotating shaft 26, and the left side and the second fixing block 24 of the first fixing block 23 are provided with a folded frame 29, and the lower side of the two folded frames 29 i...

Embodiment 3

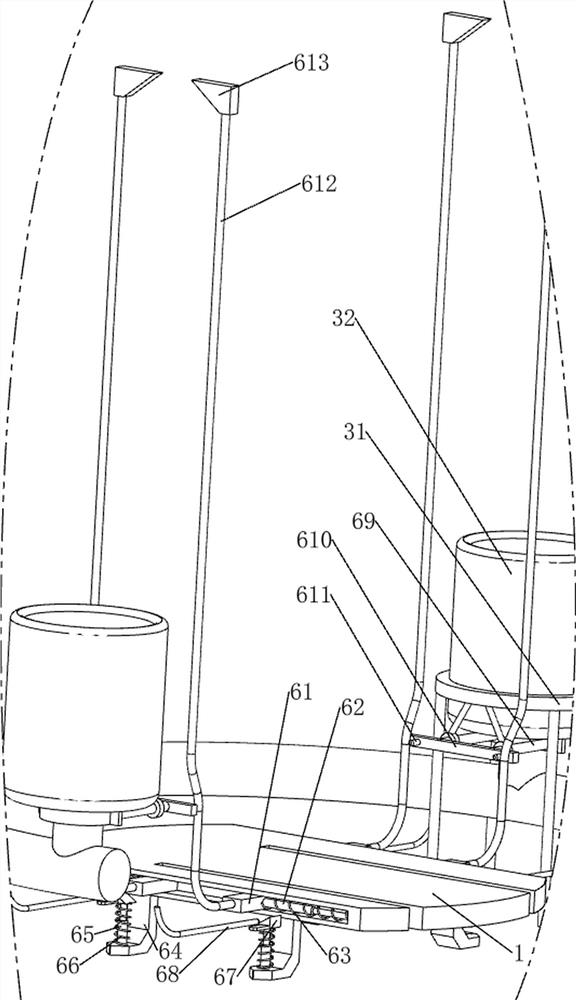

[0080] On the basis of Example 2, such as Figure 4 - Figure 7 As shown, there is also a push mechanism 4, and the pincer portion includes a first fixing plate 41, a first stretch rod 42, a first push plate 43, and a first spring 44, and the base 1 is provided. The first fixing plate 41, both sides of the left and right sides of the first fixing plate 41 are provided with a first retracting rod 42, and there is a first push plate 43, two first stretch rods. 42 is around the first spring 44, and both ends of the first spring 44 are connected to the first push plate 43 and the first fixing plate 41, respectively.

[0081] After the plurality of heating heat sinks are placed on the base 1, the first push plate 43 is moved backward due to the pressure of the heating heat sink, so that the first retracting rod 42 is contracted, the first spring 44 is compressed, when people After the first spring 44 is reset, the first push plate 43 is moved forward due to the reduction of the pressure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com