A steel bending device

A bending device and steel technology, applied in the field of metal processing, can solve problems such as inconvenience in taking steel bars, and achieve the effects of improving service life and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

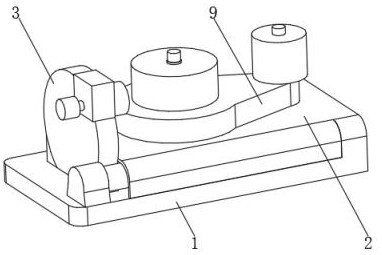

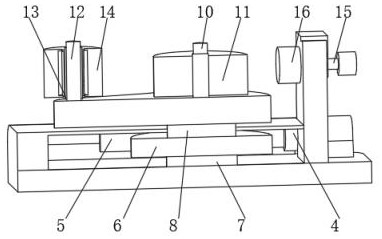

[0029] see Figure 1-4 , the present invention provides a technical solution: a steel bending device, including a bottom plate 1, the top of the bottom plate 1 is fixedly connected with a dust cover 2, and the side of the bottom plate 1 close to the dust cover 2 is fixedly connected with a fixed side plate 3, One side of the fixed side plate 3 is fixedly connected with a hydraulic telescopic rod 4, and one end of the hydraulic telescopic rod 4 runs through the fixed side plate 3 and is fixedly connected with a rack 5, and one side of the rack 5 is meshed with a gear 6, and the bottom of the gear 6 is rotated The seat 7 is rotationally connected with the bottom plate 1, the top of the gear 6 is fixedly connected with a connection block 8, the top of the connection block 8 penetrates the dust cover 2 and is fixedly connected with a turntable 9, and the side of the turntable 9 away from the connection block 8 is fixedly connected with a connection rod 10 The outer side of the con...

Embodiment 2

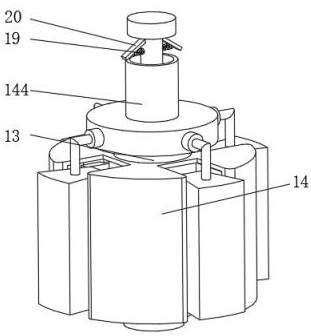

[0037] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, one end of the electric push rod 15 penetrates through the fixed side plate 3 and is fixedly connected with a clamping device 16, the clamping device 16 includes a bottom frame 161, and the outside of the bottom frame 161 Fixedly connected with the electric push rod 15 , a telescopic spring 162 is mounted symmetrically on the inner bottom of the bottom frame 161 , and a top plate 163 is fixedly connected to the end of the telescopic spring 162 away from the bottom frame 161 .

[0038] One side of the top plate 163 is fixedly connected with an elastic rod 164, one end of the elastic rod 164 runs through one side of the top plate 163, an elastic air bag 165 is installed inside the bottom frame 161, and one side of the top plate 163 is uniformly provided with round holes 166, and the round holes 166 An elastic rubber sheet 167 is fixedly connected to the inner wall of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com